Stainless HRB500 Deformed Steel Bar with 6M, 9M,12M or As Required

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Stainless HRB500 Deformed Steel Bar with 6M, 9M,12M or As Required at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Stainless HRB500 Deformed Steel Bar with 6M, 9M,12M or As Required are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Stainless HRB500 Deformed Steel Bar with 6M, 9M,12M or As Required are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Specifications of Stainless HRB500 Deformed Steel Bar with 6M, 9M,12M or As Required:

Standard | GB | HRB500 | |

Diameter | 6mm,8mm,10mm,12mm,14mm,16mm,18mm,20mm, 22mm,25mm,28mm,32mm,36mm,40mm,50mm | ||

Length | 6M, 9M,12M or as required | ||

Payment term | TT or L/C | ||

Application | mainly used in construction industry to reinforce concrete structures and so on | ||

Quality | First quality, the goods are from Chinese big manufacturers. | ||

Type | Hot rolled deformed steel bar | ||

Brand name | DRAGON | ||

Chemical Composition: (Please kindly find our chemistry of our material based on HRB500 as below for your information)

Grade | Technical data of the original chemical composition (%) | ||||||

C | Mn | Si | S | P | V | ||

HRB500 | ≤0.25 | ≤1.60 | ≤0.80 | ≤0.045 | ≤0.045 | 0.08-0.12 | |

Physical capability | |||||||

Yield Strength (N/cm²) | Tensile Strength (N/cm²) | Elongation (%) | |||||

≥500 | ≥630 | ≥12 | |||||

Theoretical weight and section area of each diameter as below for your information:

Diameter(mm) | Section area (mm²) | Mass(kg/m) | Weight of 12m bar(kg) |

6 | 28.27 | 0.222 | 2.664 |

8 | 50.27 | 0.395 | 4.74 |

10 | 78.54 | 0.617 | 7.404 |

12 | 113.1 | 0.888 | 10.656 |

14 | 153.9 | 1.21 | 14.52 |

16 | 201.1 | 1.58 | 18.96 |

18 | 254.5 | 2.00 | 24 |

20 | 314.2 | 2.47 | 29.64 |

22 | 380.1 | 2.98 | 35.76 |

25 | 490.9 | 3.85 | 46.2 |

28 | 615.8 | 4.83 | 57.96 |

32 | 804.2 | 6.31 | 75.72 |

36 | 1018 | 7.99 | 98.88 |

40 | 1257 | 9.87 | 118.44 |

50 | 1964 | 15.42 | 185.04 |

Usage and Applications of Stainless HRB500 Deformed Steel Bar with 6M, 9M,12M or As Required:

Deformed bar is widely used in buildings, bridges, roads and other engineering construction. Big to highways, railways, bridges, culverts, tunnels, public facilities such as flood control, dam, small to housing construction, beam, column, wall and the foundation of the plate, deformed bar is an integral structure material. With the development of world economy and the vigorous development of infrastructure construction, real estate, the demand for deformed bar will be larger and larger..

Packaging & Delivery of HRB500 Deformed Steel Bar:

Packaging Detail: products are packed in bundle and then shipped by container or bulk vessel, deformed bar is usually naked strapping delivery, when storing, please pay attention to moisture proof. The performance of rust will produce adverse effect.

Each bundle weight: 2-3MT, or as required

Delivery Detail: within 45 days after received advanced payment or LC.

Label: to be specified by customer, generally, each bundle has 1-2 labels

Trade terms: FOB, CFR, CIF

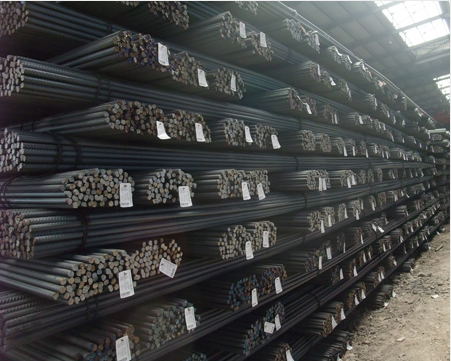

Deformed Steel Bar in stock

Note:

1. Our products are produced according to national standard (GB), if not, supply according to national standards (GB) or agreement as customer required.

2. Other Grade and Standard Deformed Steel Bar we can supply:

Grade: GR40/GR60, G460B/B500A/B500B/B500C,BST500S

Standard: ASTM, BS, DIN

The Minimum Order Quantity of these products is high, and need to be confirmed.

3. We can not only supply Deformed Steel Bar; if you need anything about building materials, please contact us for further information.

4. Please send us your detail specifications when inquire. We will reply to you as soon as possible. We sincerely hope we can establish a long stable business relationship.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

- Q: What are the factors that can cause steel rebars to corrode prematurely?

- Premature corrosion of steel rebars can be influenced by various factors. Some of these include: 1. Moisture exposure: The presence of moisture is a primary catalyst for rebar corrosion. Prolonged exposure to water or high humidity levels can lead to rust or oxidation on the rebar surface. 2. Chloride ions: The corrosion process of steel rebars can be accelerated by chloride ions, commonly found in seawater or de-icing salts. These ions can enter the concrete cover and come into contact with the rebar, causing faster corrosion. 3. Carbonation of concrete: Concrete carbonation occurs when atmospheric carbon dioxide reacts with the alkaline components of concrete. This process reduces pH levels, diminishing the concrete cover's ability to passivate and increasing the likelihood of rebar corrosion. 4. Inadequate concrete cover: Insufficient concrete cover exposes rebars to external elements like moisture and chloride ions, leading to accelerated corrosion. Poor construction practices or inadequate design specifications can result in insufficient cover. 5. Poor concrete quality: Low-quality concrete used in construction may contain impurities or lack proper curing, making the concrete more permeable. This allows harmful substances like moisture and chlorides to penetrate easily, causing premature rebar corrosion. 6. Galvanic corrosion: Galvanic corrosion occurs when dissimilar metals come into contact in the presence of an electrolyte, such as moisture. For instance, if steel rebars come in contact with aluminum or copper materials, galvanic corrosion can occur. 7. Construction defects: Issues during the construction phase, such as inadequate workmanship or insufficient protective measures, can contribute to premature rebar corrosion. Examples include poor concrete compaction, improper reinforcement placement, or inadequate waterproofing. To prevent premature corrosion of steel rebars, it is essential to use high-quality materials, ensure adequate concrete cover, apply corrosion-resistant coatings or inhibitors, and employ appropriate construction practices. Regular inspections and maintenance can also help identify and address potential corrosion issues before they worsen.

- Q: How do steel rebars enhance the bond between concrete and reinforcement?

- Steel rebars enhance the bond between concrete and reinforcement through various mechanisms. Firstly, the presence of rebars in concrete increases the mechanical interlock between the two materials. As concrete is poured around the rebars, it fills the gaps between the steel bars, creating a strong bond when it hardens. This mechanical interlock helps to prevent the separation of concrete and reinforcement, especially under tensile loads. Secondly, steel rebars enhance the bond by providing additional surface area for adhesion. The rough texture of the rebars allows the concrete to grip onto the steel surface, creating a stronger bond. This adhesion is further improved by the corrosion products that form on the surface of the steel rebars over time. These products create a rougher surface, increasing the bond strength between the concrete and reinforcement. Thirdly, rebars act as load transfer devices in concrete structures. When external forces are applied to the structure, the rebars distribute and transfer these forces to the surrounding concrete. This load transfer mechanism helps to improve the overall structural integrity and performance of the concrete element. Additionally, steel rebars also enhance the bond between concrete and reinforcement through their ability to resist deformation. Under tensile loads, the rebars elongate and absorb the stress, preventing the concrete from cracking. This prevents the development of cracks that could weaken the bond between the two materials. In summary, steel rebars enhance the bond between concrete and reinforcement by providing mechanical interlock, increased surface area for adhesion, load transfer capabilities, and resistance to deformation. These factors collectively contribute to the overall strength, durability, and performance of reinforced concrete structures.

- Q: What is the maximum length of a steel rebar available in the market?

- The maximum length of a steel rebar available in the market can vary depending on the manufacturer and the specific needs of the construction industry. However, the most commonly available lengths of steel rebar range from 20 feet (6 meters) to 60 feet (18 meters). These lengths are typically preferred due to transportation and handling constraints. However, it is important to note that custom lengths can be specially ordered from manufacturers to meet specific project requirements.

- Q: What is the average tensile strength of steel rebars?

- The average tensile strength of steel rebars typically ranges from 400 to 600 megapascals (MPa).

- Q: How do steel rebars contribute to the overall occupant comfort of a building?

- The overall occupant comfort of a building is greatly influenced by the role that steel rebars play in several ways. To begin with, steel rebars are essential for reinforcing concrete structures like walls, columns, and beams, providing the building with stability and strength. This ensures that the structure can withstand external forces such as wind, earthquakes, or heavy loads, without compromising the safety of the occupants. Additionally, the reinforced concrete helps to reduce vibrations, minimizing any discomfort caused by movement or shaking of the building. Moreover, the use of steel rebars enhances the building's durability and prevents cracks and deterioration over time. This is crucial in maintaining a comfortable indoor environment as it prevents issues like water leaks, moisture penetration, and the growth of mold or mildew. By avoiding these problems, steel rebars contribute to creating a healthy and comfortable living space for the occupants. Furthermore, steel rebars are commonly employed in the construction of high-rise buildings, which are susceptible to thermal expansion and contraction. By reinforcing the concrete structure, steel rebars assist in minimizing the effects of temperature changes, reducing the risk of structural damage, and ensuring a consistent indoor temperature. This, in turn, helps to create a comfortable environment for the occupants, regulating the temperature and preventing drafts or heat loss. Additionally, steel rebars also play a crucial role in fire resistance. Concrete structures reinforced with steel rebars have a higher fire resistance compared to other materials. This is due to the fact that steel has a high melting point and does not burn, providing occupants with extra time to evacuate the building in the event of a fire. This increased fire resistance contributes to the overall occupant comfort by enhancing their safety and reducing the risk of injuries or fatalities. In conclusion, the use of steel rebars significantly contributes to the overall occupant comfort of a building by providing stability, durability, thermal regulation, and fire resistance. Their role in reinforcing concrete structures ensures the safety, longevity, and functionality of the building, ultimately creating a comfortable and secure environment for the occupants.

- Q: Are steel rebars suitable for use in seismic zones?

- Yes, steel rebars are suitable for use in seismic zones. They are commonly used in construction to enhance the strength and durability of concrete structures, making them more resistant to seismic forces. The added reinforcement provided by steel rebars helps prevent concrete from cracking or collapsing during an earthquake, ensuring the safety and stability of the building.

- Q: How do steel rebars affect the overall structural integrity of a building?

- The overall structural integrity of a building is greatly enhanced by steel rebars. These rebars provide reinforcement and strength to the concrete, making it more durable and resistant to external forces. To begin with, the role of steel rebars in reinforced concrete structures is that of tension members. While concrete itself is strong in compression, it lacks strength in tension. By embedding steel rebars within the concrete, the composite material becomes capable of withstanding tensile forces without cracking or failing. This ensures that the building can endure the tensile stresses caused by factors like wind load, seismic activity, and ground settlement. Additionally, steel rebars aid in the even distribution and dissipation of loads throughout the structure. They enhance the load-bearing capacity of the concrete, enabling it to withstand heavier loads and prevent crack formation. Moreover, the rebars help control the spread of cracks resulting from shrinkage or thermal expansion, thereby averting catastrophic failure. Moreover, the inclusion of steel rebars enhances the ductility of the reinforced concrete structure. Ductility refers to a material's ability to deform under stress before breaking. By incorporating steel rebars, the concrete gains the capacity to bend and stretch without losing its strength. This is particularly crucial in earthquake-prone areas, as the building can absorb and dissipate the energy generated by seismic forces. Furthermore, steel rebars contribute to the durability and longevity of the building. They safeguard the concrete by preventing corrosion and degradation. When properly coated and installed, rebars act as a barrier against moisture and other corrosive elements, thereby preserving the building's structural integrity over time. In conclusion, the impact of steel rebars on the overall structural integrity of a building is significant. They reinforce the concrete, enhance its load-bearing capacity, improve ductility, and increase durability. Incorporating steel rebars into construction ensures that the building can withstand various external forces and maintain its stability and safety for an extended period.

- Q: How do steel rebars affect the overall crack width of concrete structures?

- Steel rebars affect the overall crack width of concrete structures in several ways. Firstly, rebars provide reinforcement to the concrete, making it stronger and more resistant to cracking. The presence of rebars helps distribute the tensile forces within the concrete, preventing cracks from spreading and widening. This is because when the concrete is subjected to tensile stress, the rebars take on a significant portion of the load, reducing the stress on the concrete itself and minimizing crack formation. Moreover, the use of rebars also influences the spacing and size of cracks in concrete structures. By adding rebars at specific intervals and in appropriate sizes, engineers can control the crack width of the concrete. The rebars act as barriers that limit the width of cracks by providing resistance to the tensile forces acting on the concrete. This is particularly important in structures that are exposed to heavy loads or external forces, as it helps maintain the structural integrity and durability of the concrete. Additionally, steel rebars can also affect the propagation of cracks in concrete structures. When cracks do occur, the presence of rebars can help prevent the cracks from extending further. The rebars act as anchors, holding the cracked sections of the concrete together and preventing the cracks from spreading. This is crucial in ensuring the overall stability of the structure and minimizing the risk of structural failure. In summary, steel rebars play a vital role in influencing the overall crack width of concrete structures. They enhance the strength of the concrete, distribute tensile forces, control crack spacing and size, and prevent crack propagation. By incorporating rebars into concrete structures, engineers can effectively manage and reduce the formation and severity of cracks, ensuring the longevity and safety of the structures.

- Q: Can steel rebars be used in pre-stressed or post-tensioned concrete structures?

- Yes, steel rebars can be used in both pre-stressed and post-tensioned concrete structures. In pre-stressed concrete, the rebars are tensioned before the concrete is poured, while in post-tensioned concrete, the rebars are tensioned after the concrete has hardened. The tensioned rebars help to improve the strength and durability of the concrete structures.

- Q: What is the maximum allowable percentage of rust on steel rebars?

- The maximum allowable percentage of rust on steel rebars is typically 5%. However, this may vary depending on specific industry standards and project requirements.

Send your message to us

Stainless HRB500 Deformed Steel Bar with 6M, 9M,12M or As Required

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords