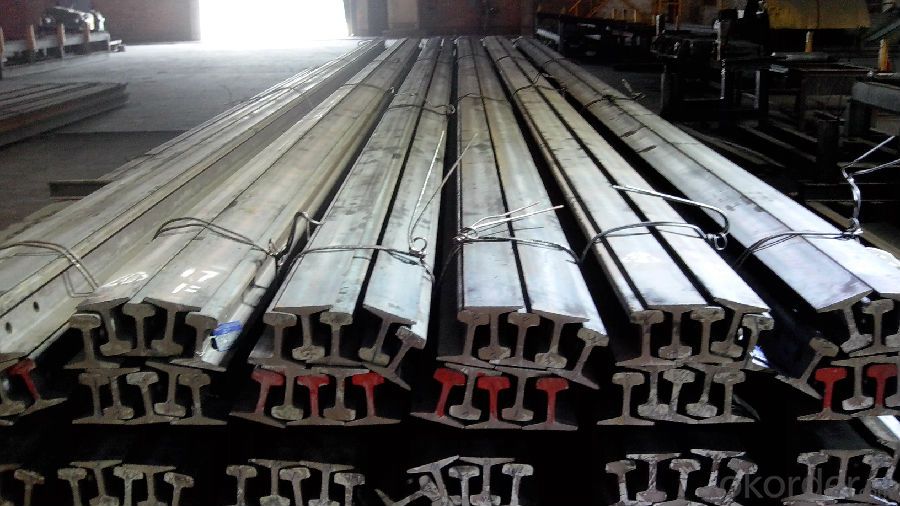

Railroad Steel Rail in High Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Railroad Steel Rail in High Quality at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to African, South American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Railroad Steel Rail in High Quality are ideal for structural applications and are widely used in forest region, Mines, factories and construction sites laid of the place such as temporary transport line and light motorcycles with line.etc.

Product Advantages:

OKorder's Railroad Steel Rail in High Quality are durable, strong, and wide variety of sizes.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: Q235, 55Q

Certificates: ISO, SGS, BV, CIQ

Length:6m, 12m,12.5m

Package: Packed in bundles and shipped by break bulk or containers.

LIGHT RAIL/HEAVY RAIL | Height (mm) | Bottom (mm) | Head width (mm) | Head height (mm) | Waist height | Bottom height (mm) | Waist thichness (mm) | Section cm2 | Mass: Kg/m |

9 | 63.50 | 63.50 | 32.10 | 17.48 | 35.72 | 10.30 | 5.90 | 11.30 | 8.94 |

12 | 69.85 | 69.85 | 38.10 | 19.85 | 37.70 | 12.30 | 7.54 | 15.54 | 12.2 |

15 | 79.37 | 79.37 | 42.86 | 22.22 | 43.65 | 13.50 | 8.33 | 19.33 | 15.2 |

22 | 93.66 | 93.66 | 50.80 | 26.99 | 50.00 | 16.67 | 10.72 | 28.39 | 22.3 |

30 | 107.95 | 107.95 | 60.33 | 30.95 | 57.55 | 19.45 | 12.30 | 38.32 | 30.1 |

FAQ:

Q1: How many tons of steel products could be loaded in containers?

A1: Usually the steel products are delivered by bulk vessel because of the large quantity and the freight. However, there are no bulk vessel enter some seaports so that we have to deliver the cargo by containers. The 6m steel product can be loaded in 20FT container, but the quantity is changed according to the size, usually from 18tons to 25tons.

Q2: what is the difference between actual weight and theoretical weight?

A2: All the section steel has two weights: actual weight and theoretical weight. Actual weight is the weighing out when the product delivered from the mill. Theoretical weight is calculated by pieces. The invoice can be based on each of them as your request.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The normal sizes with the normal grade can be produced within one month. The specific shipping date is dependent upon international and government factors, the delivery to international main port about 45-60days.

Images:

- Q: How do steel rails handle wear from train wheels?

- The wear and tear caused by train wheels is handled by steel rails in a variety of ways. Firstly, the steel used in rails is a strong alloy that can handle heavy loads and constant contact with train wheels. This ensures that the rails remain intact and do not deform or break. Regular inspections and maintenance are also conducted to detect any signs of wear or damage. This includes monitoring the condition of the rail surface, checking for cracks, and measuring wear on the rail head. By doing this, any potential issues can be addressed proactively before they become severe and pose a danger. To further reduce wear, protective coatings are often applied to steel rails. These coatings can include anti-corrosion treatments like galvanization, which prevents rust and prolongs the lifespan of the rails. They may also include friction-reducing coatings to minimize contact and friction between the wheels and rails, thereby decreasing wear. Furthermore, maintaining proper track alignment and rail profile is crucial in minimizing wear. Incorrect alignment or distorted rail profiles can result in uneven weight distribution and increased wear in specific areas of the rail. Regular inspections and adjustments are necessary to ensure proper alignment and rail profile. In conclusion, steel rails are designed to handle wear from train wheels through the use of high-strength alloys, regular maintenance and inspections, protective coatings, and proper track alignment. These measures guarantee that the rails can endure the constant pressure and friction caused by train wheels, leading to a safe and efficient railway system.

- Q: What is the impact of heavy axle loads on steel rail track maintenance?

- Heavy axle loads have a significant impact on steel rail track maintenance. When trains with heavy axle loads pass over the tracks, they exert increased pressure on the rails, causing them to deform and wear out more quickly. This results in increased maintenance requirements and expenses for rail track operators. One of the primary effects of heavy axle loads is increased rail wear. The excessive pressure exerted by heavy trains leads to accelerated metal fatigue, causing the rails to develop cracks and become more susceptible to breakage. This not only compromises the safety of the railway system but also requires more frequent inspections and repairs to prevent catastrophic failures. Moreover, heavy axle loads also contribute to increased track settlement and deformation. The continuous pounding of heavy trains puts excessive stress on the track structure, causing the ballast and subgrade to settle and shift. This results in uneven track surfaces, misalignment, and track geometry irregularities. To maintain the desired track alignment and prevent derailments, regular track realignment and releveling become essential. Additionally, heavy axle loads necessitate more frequent maintenance activities such as rail grinding and re-profiling. As the tracks wear out faster under heavy loads, grinding becomes necessary to remove surface irregularities and restore the desired rail profile. This process helps to reduce noise, improve ride quality, and extend the lifespan of the tracks. However, it also adds to the maintenance workload and costs. Furthermore, heavy axle loads can impact the longevity of railway components such as switches and crossings. These crucial elements experience increased stress and wear due to the heavy loads passing over them. As a result, they require more frequent inspections, lubrication, and replacement to ensure smooth and safe operations. Overall, the impact of heavy axle loads on steel rail track maintenance is significant. It necessitates increased monitoring, inspection, and maintenance activities to ensure the safety and efficiency of the railway system. Rail track operators must allocate additional resources and implement proactive maintenance strategies to mitigate the accelerated wear and tear caused by heavy axle loads.

- Q: Can steel rails be used for light rail transit systems?

- Yes, steel rails can be used for light rail transit systems. Steel rails are commonly used in rail tracks for various types of trains, including light rail vehicles. Steel is a durable and strong material that can withstand the weight and load of light rail vehicles, making it suitable for light rail transit systems.

- Q: What are the different types of rail fastening clips used with steel rails?

- Rail fastening clips used with steel rails come in various types, each serving to securely and efficiently fasten the rail to the track. Some commonly utilized variants include: 1. Elastic Rail Clips: These clips, featuring a metal clip with an elastic pad, offer flexibility and vibration absorption. They enjoy popularity across diverse rail applications due to their easy installation and adjustability. 2. Pandrol Clips: Named after the company that developed them, these clips find widespread use in railway systems worldwide. Their unique design enables effortless installation and maintenance while ensuring a dependable grip on the rail. 3. E-Clips: Also referred to as "Elastic Clips," these fasteners, resembling elastic rail clips, boast a distinct shape. They see extensive use in North America and Europe, valued for their easy installation and secure hold on the rail. 4. Nabla Clips: Popular in Europe, these clips sport a recognizable "N" shape, designed to firmly hold the rail in place while allowing for convenient adjustment and maintenance. They excel at resisting vertical and lateral movements. 5. KPO Clips: Commonly employed in India and other South Asian countries, these clips possess a simple design, making them effortless to install and maintain. They provide a reliable grip on the rail and suit various rail applications. 6. W-Clips: With their unique "W" shape, these clips find frequent use in North America. They are renowned for their strength and ability to withstand lateral movement, making them ideal for heavy-duty applications and high-speed rail systems. These examples represent only a small selection of the diverse range of rail fastening clips employed with steel rails. Each clip type is specifically designed to meet particular requirements and offer a secure and efficient method of fastening the rail to the track. The choice of clip depends on factors such as the rail system in use, track conditions, and desired performance.

- Q: Are steel rails affected by vibrations caused by passing trains?

- Yes, steel rails are indeed affected by vibrations caused by passing trains. These vibrations can lead to various issues such as rail wear, fatigue, and even structural damage over time. Therefore, regular monitoring and maintenance of the rails is necessary to ensure their longevity and safety.

- Q: What are the potential risks associated with steel rail installation?

- Consideration should be given to several potential risks associated with the installation of steel rails. 1. Workers face safety hazards during the installation process, including accidents and injuries caused by the weight of the rails, heavy machinery usage, or improper handling and lifting techniques. There is also a risk of slips, trips, and falls while working on elevated surfaces or in challenging weather conditions. 2. Infrastructure damage can occur during steel rail installation when trenches are dug or holes are drilled for rail placement. This poses a risk to existing underground utilities, such as gas lines, water pipes, or electrical cables. Accidental damage to these components can disrupt essential services, necessitate costly repairs, and even result in dangerous situations like gas leaks or electrical hazards. 3. The installation process can have environmental impacts, such as vegetation removal, excavation, or earthmoving activities. Without proper erosion control measures, this can lead to soil erosion, habitat disturbance, and potential pollution of nearby water bodies. Additionally, the noise and vibrations generated during rail installation can negatively affect local wildlife and ecosystems. 4. Steel rail installation projects may encounter unexpected challenges, leading to cost overruns and delays. These challenges can include unforeseen ground conditions, permitting issues, or design errors. Delays in rail installation can disrupt transportation networks, impacting commuters, businesses, and overall economic activity. 5. Inadequate planning, design, or execution of steel rail installation can result in operational risks once the rail system is in use. These risks include track misalignment, excessive wear, or failure of the rail infrastructure, which can lead to derailments or service disruptions. Regular maintenance and inspection are crucial to mitigate these risks and ensure the rail system operates safely and efficiently. Proper planning, risk assessment, and implementation of appropriate safety measures are essential for project managers, engineers, and stakeholders involved in steel rail installation to identify and address these potential risks.

- Q: How do steel rails handle heavy axle loadings?

- Steel rails are able to handle heavy axle loadings due to their high strength and durability. The steel material used in rails has excellent load-bearing capacity and can withstand the weight of heavy trains passing over them. Additionally, steel rails are designed to distribute the weight evenly, reducing the stress on individual sections and ensuring a safe and stable track for trains to travel on.

- Q: What is the role of steel rails in railway signaling systems?

- The role of steel rails in railway signaling systems is to provide a stable and secure path for trains to travel on. The steel rails act as a guide for the train's wheels, ensuring that it stays on track and follows the designated route. Additionally, the steel rails also play a crucial role in transmitting electrical signals for various signaling systems, such as track circuits, which help detect the presence of trains and control their movements. Overall, steel rails are essential for maintaining safety and efficiency in railway signaling systems.

- Q: What are the safety standards for steel rails?

- The safety standards for steel rails vary depending on the country and specific application, but generally, they include factors such as the material quality, dimensions, hardness, strength, and resistance to corrosion and wear. These standards also cover specifications for rail installation, maintenance, and inspection to ensure proper alignment, stability, and overall safety of the rail system.

- Q: How are steel rails protected from damage caused by sandstorms?

- Steel rails are protected from damage caused by sandstorms through various measures. Firstly, rail tracks are typically designed with a specific profile that helps prevent sand accumulation. The shape of the rails is designed to minimize any areas where sand can gather, ensuring that the wind can blow the sand away more easily. Additionally, rail tracks are often treated with a protective coating or paint that helps prevent sand particles from sticking to the surface. This coating not only makes it easier to remove sand but also provides a barrier against corrosion and wear. Railway companies also employ regular maintenance practices to protect steel rails from sandstorm damage. These include routine inspections to identify any areas where sand accumulation may be occurring and promptly clearing or cleaning these areas. During sandstorms or periods of high sand activity, rail operators may also increase maintenance efforts or temporarily halt train operations to prevent excessive sand build-up. Moreover, sand fences or barriers are sometimes installed along the rail tracks in areas prone to sandstorms. These fences act as a physical barrier, reducing the amount of sand that reaches the tracks and minimizing the potential for damage. Overall, a combination of preventive measures, regular maintenance, and protective coatings help safeguard steel rails from the damaging effects of sandstorms, ensuring the safe and efficient operation of railways.

Send your message to us

Railroad Steel Rail in High Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords