Q13(QB)250 MACHINE VICE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are a specialized company for machine vises , whoseproducts are exported to Europe and America as well as developed countries .Wehave Q12,Q13,Q41,QM,QMN series .All the products have high precision ,and reasonabledesigns and reach the JB/T2329-11 standards .

Weare insisting that the quality is first and reputation is the best. We refocusing on our quality and innovation , We are looking forward to havingopportunities to set up more business relations with customers from all overthe word and establish the long-term cooperation with best products and perfectafter-service.

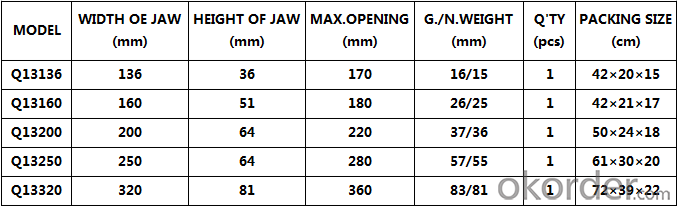

Q13(QB) SeriesMachine Vice

Performance and character:

1. It adopts the high-quality cast irons.

2. Both parallelismand verticality about the two jaws are 0.025mm/100mm.

3. It is widelyused for the milling machine and the drilling machine to process some surface,slots and holes.

- Q: What does mechanical forceps mean?

- The fitter is the method of working the engineering material with the handheld tool. The work of the fitter is composed mainly of the workbench and vice.

- Q: What is the commonly used workpiece in milling machine

- The machine has a vice with vice. Hope to help you.There are also versatile fixture and special fixture

- Q: How to find a positive two vice

- Recommended to directly purchase side-by-side vise, because the vice of this style guide is high, it is convenient to use, whether you are using several, and each can be used independently, and can be installed to the machine tool worktable by side.

- Q: What is the industry, what field?

- Generally called vice is refers to the mechanical processing vice, so the mechanical processing industry to the purpose of the application is for the clamping fixed to the workpieces, the biggest characteristics is a different style with different structure and the precision of the standard ~

- Q: Do you use a hammer to hit the handle with a clamp?

- The following statement is true (A) A. use A hammer to hit the handle when clamping the workpiece with A vice B. saw a blade tightening with two fingers to tighten the butterfly nut. It feels hard to pull the saw blade In order to increase the efficiency of sawing and cutting, the force should be applied properly when pulling the handsaw The iron filings of the vice of a vice, which can be blown off by the mouth or by hand

- Q: What does Taiwan's vice President stand for

- So according to metric units, the tongs of the tongs are 200mm.

- Q: What should be noticed using a bench vice?

- Do not knock on the active clamp and smooth surface. (4) the surface should be cleaned and lubricated regularly to prevent rust.

- Q: What is mechanical vice material

- Chromium vanadium steel, chemical symbol CRV, which is a high quality in steel,

- Q: The working principle of machine vice

- Provisions of clamp body can be installed on the machine working table, function frame, using a wrench, eight screw rotating parts can drive the nut for around 9 parts move, because the helix has two movements:

- Q: The difference between bench vice and vice! ~! ??

- Flat pliers are a kind of common jig for machine tools, which need to be used with machine tool, milling machine and planer.

Send your message to us

Q13(QB)250 MACHINE VICE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches