Q13(QB)200 MACHINE VICE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are a specialized company for machine vises , whoseproducts are exported to Europe and America as well as developed countries .Wehave Q12,Q13,Q41,QM,QMN series .All the products have high precision ,and reasonabledesigns and reach the JB/T2329-11 standards .

Weare insisting that the quality is first and reputation is the best. We refocusing on our quality and innovation , We are looking forward to havingopportunities to set up more business relations with customers from all overthe word and establish the long-term cooperation with best products and perfectafter-service.

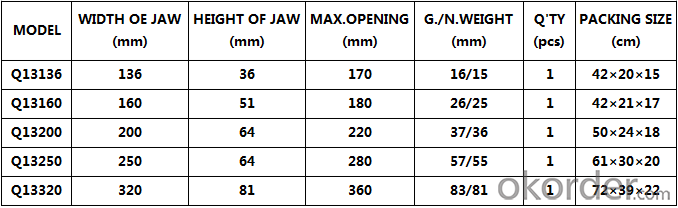

Q13(QB) SeriesMachine Vice

Performance and character:

1. It adopts the high-quality cast irons.

2. Both parallelismand verticality about the two jaws are 0.025mm/100mm.

3. It is widelyused for the milling machine and the drilling machine to process some surface,slots and holes.

- Q: Is there a god who is good at drawing mechanical drawings?

- The bench vice is the necessary tool for the fitter, and is also the source of the fitter's name, because most of the work of the fitter is vise

- Q: Will the bench work on the bench vice?

- The work of the bench is based on the work of the fitter, which is made of wood

- Q: The bench vice is used by the fitter to have which two kinds

- vise The use and type of bench vice: A and USES: a bench vice is specialized in holding the work piece, B, specification: the size of the tongs is the width of the tongs, and the usual 100mm, 125 mm and 150 mm, etc C, type: type has a fixed and rotary type

- Q: What is the industry, what field?

- Vice is generally used in mechanical processing industry, divided into two kinds of machine with vice and vise, the former is used for machining on the machine tool clamping for processing parts, which is installed on the bench work clamping for processing parts, so that the bench manual operation.

- Q: Use of bench vice (simple point)

- When the vice is installed on the tongs, the sweet mouth of the clamps must be placed outside the edge of the tongs.

- Q: Describe the method of attaching the piece of work to the machining center with vice clamp.

- Put it flat, at least you will use a percentage of the watch to tighten the surface of the face.

- Q: What does Taiwan's vice President stand for

- The inches here are the units used in the past: inches. The length of an inch is a metric unit of 25.4mm, and a metric system of 8 inches is 203.2mm.

- Q: Several basic USES of bench vice

- Installed on the bench, the width of the tongs is the calibration specification. Common specifications range from 75mm to 300mm.

- Q: Is the thread of a vice with a zigzag thread

- Inside is a t-nut, the letter "Tr". It is usually 4-6 pressure, single thread nut

- Q: What type are the tongs?

- There are many types of silk rods, many of them, sometimes with the manufacturer's abbreviation, serial number, etc., so it is impossible to say

Send your message to us

Q13(QB)200 MACHINE VICE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords