QM16100 ACCU-LOCK MACHINE VICE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are a specialized company for machine vises , whoseproducts are exported to Europe and America as well as developed countries .Wehave Q12,Q13,Q41,QM,QMN series .All the products have high precision ,and reasonabledesigns and reach the JB/T2329-11 standards .

Weare insisting that the quality is first and reputation is the best. We refocusing on our quality and innovation , We are looking forward to havingopportunities to set up more business relations with customers from all overthe word and establish the long-term cooperation with best products and perfectafter-service.

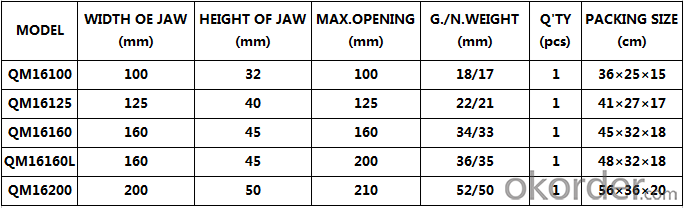

QM Series MachineVice

Performance and character:

1. It is one of main attachmentsfor milling、drillingmachine ,it is particularly suitable for the finishing of precision parts.

2. The accuracy of vice (parallelismand squareness) is 0.025mm/100mm.

3. The special segment in themovable jaw forces the vertical pressure downward when the horizontal pressureworks, so that this jaw does not lift the work piece.

4. Four positions allow extracapacity to change opening of jaw.

- Q: What does mechanical forceps mean?

- Vice. It is the vice that is attached to the table. Also known as the vise.

- Q: What are the characteristics and advantages of precision vice?

- Precision pliers structure similar to ordinary clamp structure, is a clamp body activity, fixed jaw, jaw, drive screw, nut, is only relevant parts of higher precision, cooperate more closely. There is no necessary relationship between structure principle and precision

- Q: The approximate variety of a vice

- The specification of table vice is indicated by the width of tongs, 100mm, 125mm, 150mm etc. The bench vice is a common fixture for holding the workpiece. There are two kinds of fixed and rotating type. According to the appearance function cent: have the anvil and no anvil two kinds.

- Q: What is the commonly used workpiece in milling machine

- Flat nose pliers, pressed bolts, v-shaped iron, divided head top, split head chuck (vertical), dividing head (tilt)

- Q: Do you use a hammer to hit the handle with a clamp?

- The following statement is true (A) A. use A hammer to hit the handle when clamping the workpiece with A vice B. saw a blade tightening with two fingers to tighten the butterfly nut. It feels hard to pull the saw blade In order to increase the efficiency of sawing and cutting, the force should be applied properly when pulling the handsaw The iron filings of the vice of a vice, which can be blown off by the mouth or by hand

- Q: Ask questions! How large a bench vice is a carpenter?

- There are conditions for a 5-inch, heavy-duty, working, cleaning tool. Remember to buy a good brand.

- Q: What should be noticed using a bench vice?

- When clamping the piece of work, it should be pressed properly, only with the handboard grip, and no other tool should be used. (2) when working hard, try to keep the force toward the fixed pliers.

- Q: Which is the strength of the hardware and wooden bench pliers?

- Play gold worker's bench clamp. Play woodworking small pieces can be used to make wooden clamp.. big piece afraid is still need carpenter's bench clamp.

- Q: What is the width of the tongs? Is it the same thing?

- I check "QBT 1558.2-1992 vice bench vice", The width of the vice jaw is the same as the opening. If you want "QBT 1558.2-1992 vice bench vice" electronic press, give email address.

- Q: The difference between bench vice and vice! ~! ??

- he feature is that there is no chopping on the work surface, the accuracy is higher than the bench clamp, the function is similar to the tongs, and they are all the same.

Send your message to us

QM16100 ACCU-LOCK MACHINE VICE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches