QM16160L ACCU-LOCK MACHINE VICE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are a specialized company for machine vises , whoseproducts are exported to Europe and America as well as developed countries .Wehave Q12,Q13,Q41,QM,QMN series .All the products have high precision ,and reasonabledesigns and reach the JB/T2329-11 standards .

Weare insisting that the quality is first and reputation is the best. We refocusing on our quality and innovation , We are looking forward to havingopportunities to set up more business relations with customers from all overthe word and establish the long-term cooperation with best products and perfectafter-service.

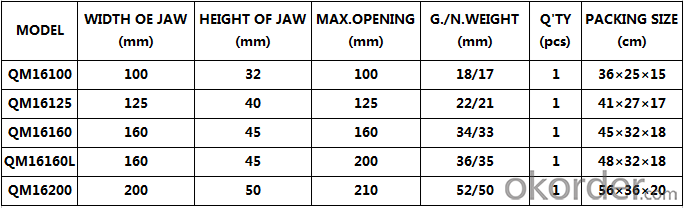

QM Series MachineVice

Performance and character:

1. It is one of main attachmentsfor milling、drillingmachine ,it is particularly suitable for the finishing of precision parts.

2. The accuracy of vice (parallelismand squareness) is 0.025mm/100mm.

3. The special segment in themovable jaw forces the vertical pressure downward when the horizontal pressureworks, so that this jaw does not lift the work piece.

4. Four positions allow extracapacity to change opening of jaw.

- Q: Pneumatic vice and hydraulic vice are good

- Hydraulic pliers are used for hydraulic oil, which is just different

- Q: Numerical control milling machine vice school table

- With a dial indicato.I hope my answer will help you.r

- Q: How do you mill a step up the miller's vice

- If necessary for holding the piece, remove the clamp and replace it with homemade tongs. Don't lose this good part for some reason.

- Q: Is there a god who is good at drawing mechanical drawings?

- On the tongs, such as saw, file, chisel, and assembly and disassembly of parts. Installed on the bench, the width of the tongs is the calibration specification. Common specifications range from 75mm to 300mm. Use of bench vice: the machine is on the workbench, which can be used to clip the workpiece, which is a necessary tool for the fitter workshop.

- Q: How to find a positive two vice

- Recommended to directly purchase side-by-side vise, because the vice of this style guide is high, it is convenient to use, whether you are using several, and each can be used independently, and can be installed to the machine tool worktable by side.

- Q: What is the use of a vice

- Machine vise has a very wide range of USES, common in processing various parts on machine tool clamping. Such as milling machine, up &will waste on the bed, drilling machine is commonly used when machining parts with vice clamp fixed parts processed. Machine use vise has the advantages of simple structure, reliable clamping.

- Q: What should be noticed using a bench vice?

- The clamp shall not be made of the casing or hammer, and the workpiece shall not exceed two-thirds of the maximum travel of the tongs

- Q: What is the width of the tongs? Is it the same thing?

- The width of the jaw is the width of the clamp. Opening is the maximum distance between two holding ends.

- Q: What is the use of bench vice

- Installed on the bench, the width of the tongs is the calibration specification. Common specifications range from 75mm to 300mm. Use of bench vice: the machine is on the workbench, which can be used to clip the workpiece, which is a necessary tool for the fitter workshop.

- Q: How do you beat the sink hole of the pincers with two screws, with a drill or a milling cutter

- Method has a good variety of, see which one do you prefer, today the mood is good, just tell you two ways, vise has medium commonly used three, the main difference between the two screws of center distance, the most common and I guess you said is belong to medium, two hole center distance is 98 MM, the bottom of the grip to 23 MM hole center distance. (punch position must be less than 23 MM) with metric coarse threads M10, general specification M10 screw, screw diameter of 10 MM, (through hole, is bigger than him, 11, 12 MM or so can) hat head size is between 14 to 16, more than he can Lazy person programming: 8MM thick milling cutter screw, milling through hole 11, total thickness left 5 to 10MM above all milling more than 16MM head hole Most efficient programming, 11 drilling, 16 drilling to 5-10mm, thick milling cutter with two knives milling flat head holes It is not impossible to use only the drill bit, but the force area is too small and the lock screws are not very good and easy to loosen. You will regret it when you loosen the clamp, so it is absolutely not recommended to drill with a drill

Send your message to us

QM16160L ACCU-LOCK MACHINE VICE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches