Q41(QHK)100 MACHINE VICE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are a specialized company for machine vises , whoseproducts are exported to Europe and America as well as developed countries .Wehave Q12,Q13,Q41,QM,QMN series .All the products have high precision ,and reasonabledesigns and reach the JB/T2329-11 standards .

Weare insisting that the quality is first and reputation is the best. We refocusing on our quality and innovation , We are looking forward to havingopportunities to set up more business relations with customers from all overthe word and establish the long-term cooperation with best products and perfectafter-service.

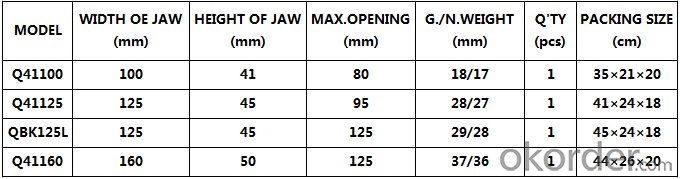

Q41(QHK) SeriesMachine Vice

Performance and character:

1. It adopts the high-quality cast irons.

2. Both parallelismand verticality about the two jaws are 0.025mm/100mm.

3. The vice can beadjusted and locked at random from the horizontal position to the verticalposition (0°-90°)with swiveling base being rotated 360°.

4. It can be widelyused for processing all kinds angels of surface, slots and holes.

- Q: Pneumatic vice and hydraulic vice are good

- The price ranges from a thousand yuan to a thousand yuan。I hope my answer will help you。

- Q: Numerical control milling machine vice school table

- With a dial indicato.I hope my answer will help you.r

- Q: Who knows the calculation and selection of the tongs?

- According to the requirement of dustproof protection and the requirement of interplay and pre-tightening, the appropriate structure can be chosen.

- Q: Is there a god who is good at drawing mechanical drawings?

- Bench vice, also called vice, bench vice. A bench vice is a common fixture for holding a piece of work. The equipment is on the workbench, which can be used to clip the workpiece, which is a necessary tool for the fitter workshop. The rotary clamp can rotate to make the workpiece rotate to the appropriate position.

- Q: What is the meaning of 1/8-3 of the tongs in the pipe

- A pair of pliers that can clamp down to the size of a tube of 1/8-3.I hope my answer will help you.

- Q: Ask questions! How large a bench vice is a carpenter?

- Woodworking is not suitable for use of bench vice, different USES.I hope my answer will help you.

- Q: Which is the strength of the hardware and wooden bench pliers?

- So, a slightly stout value is not high of the bench vise is a must, choose a platform with small bench vise can satisfy some sporadic and at the same time, won't make you heartache; The machine can be used to clip delicate small pieces. The idea is that instead of buying a single piece of die-cast steel bench clamp that is nearly 1,000 yuan, you can buy a machine with a flat tongs and a regular bench clamp, and the price is still in surplus. Buy instruments of cross-industry tend to make you happy surprises, for example, a flask with a frosted bottle stopper chemical sealing is good and cheap, is a good vessels of coffee beans, red wine, etc, and some of the bottles and hundreds of yuan coffee storage bottle sealing is less than the price at the same time and several times more expensive.

- Q: Is the thread of a vice with a zigzag thread

- So don't generalize! The truth is the combination of theory.I hope my answer will help you

- Q: How to position the pongs

- Flat vice positioning: the first is to place the flat to the position of vice (basically flat) clean up, and then a layer of anti-rust oil to clean up the bottom of the vice, a layer of anti-rust oil reservation will vice placed in want to place the position of vice, plain vice grip on to the workers themselves, visual jaw to workers from each of the two surfaces of roughly parallel to the right direction, will be flat on both sides of the vice two fixed screw knob (also some flat vice with hexagonal screw nut) must be clockwise gently lock moderately,

- Q: What is the use of bench vice

- Essential tool vise for fitter, and fitter for the name of the source, because the bench most of the work is done on the vise, such as saws, file, chisel, and the components of the assembly and disassembly.

Send your message to us

Q41(QHK)100 MACHINE VICE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches