Q12(QH)160 MACHINE VICE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are a specialized company for machine vises , whoseproducts are exported to Europe and America as well as developed countries .Wehave Q12,Q13,Q41,QM,QMN series .All the products have high precision ,and reasonabledesigns and reach the JB/T2329-11 standards .

Weare insisting that the quality is first and reputation is the best. We refocusing on our quality and innovation , We are looking forward to havingopportunities to set up more business relations with customers from all overthe word and establish the long-term cooperation with best products and perfectafter-service.

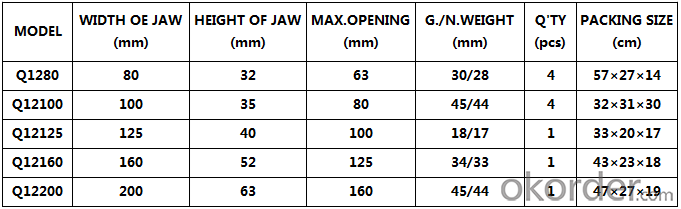

Q12(QH)series Machine Vice:

Performanceand character:

1. It adopts the high-quality castirons.

2. Both parallelism andverticality about the two jaws are 0.025mm/100mm.

3. It is widely used for themilling machine and the drilling machine to process some surface ,slots andholes.

- Q: What does mechanical forceps mean?

- Vice. It is the vice that is attached to the table. Also known as the vise.

- Q: What's the difference between a vice and a vice

- In order not to damage and maintain the surface of the tongs, place the piece of copper on the clamp. D, use the hand to move the iron to check the clamping degree, if there is loose, to show that the workpiece is not good to the padded iron, should loosen the flat tongs clamp again (4) it is not enough to be rigid: the workpiece needs to be firm, so as to prevent the clamping force from deforming the workpiece. Bench vice: use: device on the workbench, used to clip the machining workpiece, for the fitter workshop essential tool. The rotary clamp can rotate to make the workpiece rotate to the appropriate position.

- Q: How to draw a vice assembly drawing

- Draw a secondary structure. Check the proofs and revise the supplement.

- Q: How to find a positive two vice

- Then adjust the level of water level (both of which are consistent with the working table) - the magnetic watch seats are drawn on the main shaft

- Q: What is the industry, what field?

- It's going to be a lot of things, and it's a very important toolI hope my answer will help you.

- Q: Describe the method of attaching the piece of work to the machining center with vice clamp.

- So that's the same thing as the X-axis. And then fix it,I hope my answer will help you

- Q: What does Taiwan's vice President stand for

- The inches here are the units used in the past: inches. The length of an inch is a metric unit of 25.4mm, and a metric system of 8 inches is 203.2mm.

- Q: Several basic USES of bench vice

- Chinese name: vise English name: bench vice "definition: installed on the bench, with the tool of jaw clamping workpiece Essential tool vise for fitter, and fitter for the name of the source, because the bench most of the work is done on the vise, such as saws, file, chisel, and the components of the assembly and disassembly. Installed on the bench, the width of the tongs is the calibration specification. Common specifications range from 75mm to 300mm. Use of bench vice: the machine is on the workbench, which can be used to clip the workpiece, which is a necessary tool for the fitter workshop

- Q: What is the width of the tongs? Is it the same thing?

- I check "QBT 1558.2-1992 vice bench vice", The width of the vice jaw is the same as the opening. If you want "QBT 1558.2-1992 vice bench vice" electronic press, give email address.

- Q: What is the use of the screw on the pincers of the flat slot with two orifices

- These two should be used to locate the tiger's mouth.I hope my answer will help you.

Send your message to us

Q12(QH)160 MACHINE VICE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords