Q41(QHK)160 MACHINE VICE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are a specialized company for machine vises , whoseproducts are exported to Europe and America as well as developed countries .Wehave Q12,Q13,Q41,QM,QMN series .All the products have high precision ,and reasonabledesigns and reach the JB/T2329-11 standards .

Weare insisting that the quality is first and reputation is the best. We refocusing on our quality and innovation , We are looking forward to havingopportunities to set up more business relations with customers from all overthe word and establish the long-term cooperation with best products and perfectafter-service.

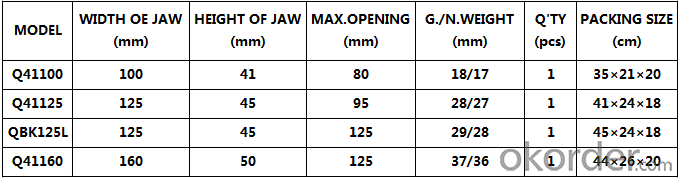

Q41(QHK) SeriesMachine Vice

Performance and character:

1. It adopts the high-quality cast irons.

2. Both parallelismand verticality about the two jaws are 0.025mm/100mm.

3. The vice can beadjusted and locked at random from the horizontal position to the verticalposition (0°-90°)with swiveling base being rotated 360°.

4. It can be widelyused for processing all kinds angels of surface, slots and holes.

- Q: One: what is a heavy bench vice? 2: what is the characteristic of heavy bench vice? What's the performance? What is it for?

- Its structure consists of forceps, base, guide nut, screw and tongs. The active tongs glide through the guide track of the guide and the fixed clamp. The screw is mounted on an active tongs, which can be rotated, but not moved, and fitted with the screw nut mounted inside the clamp. When the handle is moved to rotate the screw, it can be used to move the clamps to move the shaft of the clamps, which can be tightened or relaxed. The spring is fastened to the screw with a baffle and open pin, which is used to loosen the screw and allow the active clamp to exit in time. The clamp is fitted with steel tongs and screws fixed with screws. The work surface of the tongs is intersected, which makes it difficult to slip when the workpiece is clamped. The tongs are hardened by heat treatment and have good abrasion resistance. Fixed clamp body in a seat, and can rotate axis rotation, when transferred to the requirements of the direction, turn the clamping handle make the clamping screw tightening, can be in the clamping plate under the action of the fixed clamp body is solid and tight. There are three bolt holes in the seat to be fixed with the clamp. The specification of table vice is indicated by the width of tongs, 100mm, 125mm, 150mm etc.

- Q: Who knows the calculation and selection of the tongs?

- Hyman, lu on this so you can choose, for example, when the time slot is allowed to exist (such as vertical motion), can be used with single circular arc form thread groove of single nut ball screw pair

- Q: Is there a god who is good at drawing mechanical drawings?

- Bench vice, also called vice, bench vice. A bench vice is a common fixture for holding a piece of work. The equipment is on the workbench, which can be used to clip the workpiece, which is a necessary tool for the fitter workshop. The rotary clamp can rotate to make the workpiece rotate to the appropriate position.

- Q: What do you mean by rotating mechanical vice

- Adjustable bench vice,I hope my answer will help you。

- Q: Push it to the required piece of work, then lock the screw with the inner hexagon wrench to achieve a tight end. What I want to know is the design structure of it, if you have this kind of vice in your hand, you can show me a few pictures, especially the lock structure underneath it. There is a drawing change. If you know what it's called, give it a name,

- This structure used to be used mainly for the precision flat tongs used in grinding machines.

- Q: How to find a positive two vice

- Use common vice for two USES, first to proofread the equal height of the vise, and to adjust the lower vise with a gasket (the can of our life can be used).

- Q: What is mechanical vice material

- Carbon steel, a relatively poor quality, is now the most material on the market, and the price is lower

- Q: How to fix the bench vice of the bench bench

- The bench vice has three fixed screw eyes, corresponding to the installation area of the operator, type three equal diameter screw holes, and the screw nut is fixed

- Q: Who has a parts drawing and assembly diagram for a vice?

- Abcug BBS has this assembled video and file upload, in the assembly and simulation section. You can't find the right answer

- Q: What is the use of bench vice

- Chinese name: table vice Bench vice Definition: a tool that is installed on a bench with a clamp holder

Send your message to us

Q41(QHK)160 MACHINE VICE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords