QM16100N ACCU-LOCK PRECISION MACHINE VICE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are a specialized company for machine vises , whoseproducts are exported to Europe and America as well as developed countries .Wehave Q12,Q13,Q41,QM,QMN series .All the products have high precision ,and reasonabledesigns and reach the JB/T2329-11 standards .

Weare insisting that the quality is first and reputation is the best. We refocusing on our quality and innovation , We are looking forward to havingopportunities to set up more business relations with customers from all overthe word and establish the long-term cooperation with best products and perfectafter-service.

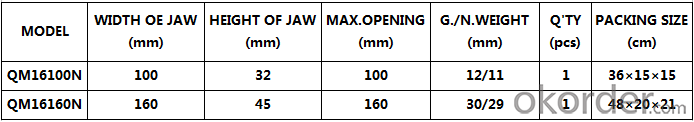

QMN Series Machine Vice

Performance and character:

1. It adopts the ductile cast ironwith high durability.

2. The locking structure with theangle-fixed shape can prevent the work piece fron rising during the operation.

3. Both parallelism and verticalityabout the two jaws are 0.025mm/100mm.

4. It can be used by single set orseveral sets side by side.

5. It is widely used for precision machines inthe machine center.

- Q: Pneumatic vice and hydraulic vice are good

- The price ranges from a thousand yuan to a thousand yuan。I hope my answer will help you。

- Q: Who knows the calculation and selection of the tongs?

- According to the requirement of dustproof protection and the requirement of interplay and pre-tightening, the appropriate structure can be chosen.

- Q: How to draw a vice assembly drawing

- Complete the complete picture, deepen the drawing line, draw the section line, mark the necessary dimensions, the tolerance and technical requirements, mark the parts serial number, fill in the detail form and the title bar. Thank you for your trouble! If you don't understand, please continue to ask...

- Q: The approximate variety of a vice

- There is a tongs and a rotary table, and there are two hooks that are pressing down on it, the same principle as the central pincers. Do you know the name of the pliers, or do you know where to sell them?

- Q: The bench vice is used by the fitter to have which two kinds

- The working principle of rotary table vice: Rotary table vice clamp body can be relative to the base of rotary (detailed in figure 1-2 a), can satisfy different azimuth processing need, easy to use, wide application.

- Q: Use of bench vice (simple point)

- When the vice is installed on the tongs, the sweet mouth of the clamps must be placed outside the edge of the tongs.

- Q: What is the use of a vice

- Our company is using the vice of the machine of the dongguan company machine, the quality is very good.

- Q: What does Taiwan's vice President stand for

- The eight inches of the bench means the length of the tongs.

- Q: What should be noticed using a bench vice?

- Do not knock on the active clamp and smooth surface. (4) the surface should be cleaned and lubricated regularly to prevent rust.

- Q: All of the double force vice is designed with the same high design?

- The standard family is different from each other, and I understand that most of them are lower than the accuracy tables above you What is alleged to be the vice of the vice that is the same as the brand only, is to tell the client to be able to be able to be able to be able to be able to use a few times

Send your message to us

QM16100N ACCU-LOCK PRECISION MACHINE VICE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches