Q12(QH)200 MILLING MACHINE VICE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are a specialized company for machine vises , whoseproducts are exported to Europe and America as well as developed countries .Wehave Q12,Q13,Q41,QM,QMN series .All the products have high precision ,and reasonabledesigns and reach the JB/T2329-11 standards .

Weare insisting that the quality is first and reputation is the best. We refocusing on our quality and innovation , We are looking forward to havingopportunities to set up more business relations with customers from all overthe word and establish the long-term cooperation with best products and perfectafter-service.

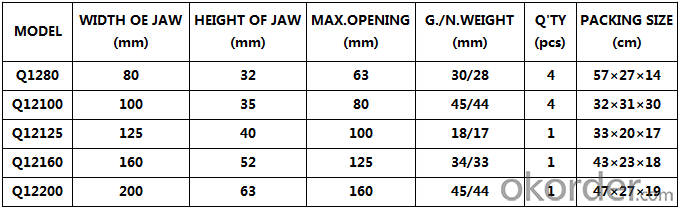

Q12(QH)series Machine Vice:

Performanceand character:

1. It adopts the high-quality castirons.

2. Both parallelism andverticality about the two jaws are 0.025mm/100mm.

3. It is widely used for themilling machine and the drilling machine to process some surface ,slots andholes.

- Q: Numerical control milling machine vice school table

- Left and right, milling cutter is high, not milling is low, slowly adjust...

- Q: Common production desk vice, 45 # steel make the clamp plate, how to make pattern

- I don't understand the pattern. In heat treatment, the size is smaller, and the temperature of the heat is increased by the maximum power of the furnace. The furnace controls the clearance. The heat preservation time of 30 min, oil cooling, 500 ℃ tempering, 1 h

- Q: What is the industry, what field?

- It should be used, but some of them are machines

- Q: Use of bench vice (simple point)

- Bench vice is a common fixture used to hold the workpiece. The purpose of the bench vice is on the workbench, which is used for holding the machining workpiece, which is a necessary tool for the fitter workshop. The rotary clamp can rotate to make the workpiece rotate to the appropriate position. The specifications of the tongs of the table are indicated by the width of the tongs, the usual specifications are 100mm, 125mm, 150mm etc. [editor this paragraph] use vise considerations: (1) the clamping workpiece to slack when appropriate, can only use hand tight grip, shall not use other tools and stronger. (2) when working hard, try to keep the force toward the fixed pliers. (3) do not knock on the active clamp and smooth surface. (4) the surface should be cleaned and lubricated regularly to prevent rust.

- Q: What is the use of a vice

- Machine vise has a very wide range of USES, common in processing various parts on machine tool clamping. Such as milling machine, up &will waste on the bed, drilling machine parts is commonly used when to clamp fixed parts processed with vice

- Q: Ask questions! How large a bench vice is a carpenter?

- Woodworking is not suitable for use of bench vice, different USES.I hope my answer will help you.

- Q: What does Taiwan's vice President stand for

- The eight inches of the bench means the length of the tongs.

- Q: What should be noticed using a bench vice?

- When clamping the piece of work, it should be pressed properly, only with the handboard grip, and no other tool should be used. (2) when working hard, try to keep the force toward the fixed pliers.

- Q: The difference between bench vice and vice! ~! ??

- Flat pliers are a kind of common jig for machine tools, which need to be used with machine tool, milling machine and planer.

- Q: All of the double force vice is designed with the same high design?

- The standard family is different from each other, and I understand that most of them are lower than the accuracy tables above you What is alleged to be the vice of the vice that is the same as the brand only, is to tell the client to be able to be able to be able to be able to be able to use a few times

Send your message to us

Q12(QH)200 MILLING MACHINE VICE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches