Pvdf Coated Direct Rolled Aluminum Circle for Food Cookware

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Direct Rolled Aluminium Circle for Food Cookware

Direct Rolled Aluminium Circle for Food Cookware are widly used in decoration field. For the painting, it depends on the using evironment. If you use in the open air, we recommend the PVDF coated aluminium coils. This kind of painting can last 15-20 years. If you use in the room, we recommend PE coated aluminium coils. The price is much more competitive.

2. Main features of Direct Rolled Aluminium Circle for Food Cookware

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

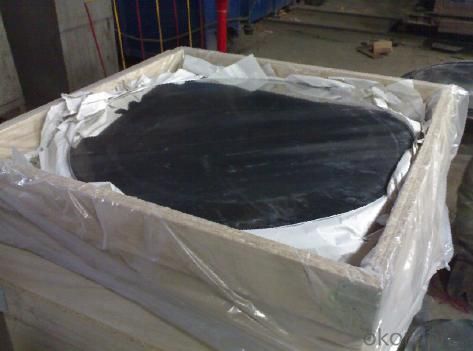

3. Image of Direct Rolled Aluminium Circle for Food Cookware

4. Product Specification of Direct Rolled Aluminium Circle for Food Cookware

| Alloy | Temper | Rolling | Thickness | Diameter |

| AA1050 | F | Hot Rolled | 0.2MM-2MM | 100MM-1500MM |

5.FAQ of Direct Rolled Aluminium Circle for Food Cookware

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: Are there any health risks associated with using aluminum sheets?

- Yes, there are potential health risks associated with using aluminum sheets. Aluminum is a neurotoxic metal that can accumulate in the body over time. Prolonged exposure to high levels of aluminum has been linked to several health issues, including respiratory problems, bone disorders, and neurodegenerative diseases such as Alzheimer's. Additionally, certain studies suggest a possible link between aluminum exposure and an increased risk of developing breast cancer. It is important to take precautions when working with aluminum sheets and minimize exposure to the metal.

- Q: What is the dielectric strength of aluminum sheets?

- The dielectric strength of aluminum sheets is typically around 20-30 kilovolts per millimeter (kV/mm).

- Q: as for heating coil and aluminum sheet, which one is better for heating?

- Heating coil has a short lifetime, and aluminum sheet for heating can be used for a long time. Stainless steel heating tube is embedded into aluminum sheet for heating, because the heating coil isn’t exposed, it can be used for a long time.

- Q: Are the aluminum sheets suitable for manufacturing architectural wall panels?

- Yes, aluminum sheets are suitable for manufacturing architectural wall panels. Aluminum is a versatile and popular material in the construction industry due to its numerous benefits. Firstly, aluminum is lightweight, making it easy to handle and install. This is especially advantageous for architectural wall panels, as it reduces the overall weight of the structure, simplifies transportation, and allows for greater flexibility in design. Additionally, aluminum offers exceptional durability and resistance to corrosion. This is crucial for wall panels, as they are exposed to various environmental elements such as rain, UV rays, and temperature changes. Aluminum's natural oxide layer provides a protective barrier, ensuring that the panels remain intact and maintain their appearance over time. Aluminum also provides excellent thermal and acoustic insulation properties. Architectural wall panels made from aluminum can help regulate the internal temperature of buildings, leading to energy savings and improved comfort for occupants. Moreover, aluminum panels help reduce noise transmission, contributing to a quieter indoor environment. Furthermore, aluminum is highly customizable in terms of shape, size, color, and finish. This allows architects and designers to create unique and visually appealing wall panel systems that complement the overall aesthetics of a building. The versatility of aluminum sheets also facilitates the integration of other materials, such as glass or stone, for added design possibilities. Lastly, aluminum is a sustainable material. It is 100% recyclable, and the energy required for recycling aluminum is significantly lower compared to the production of primary aluminum. Choosing aluminum sheets for architectural wall panels aligns with environmentally friendly practices and contributes to the reduction of carbon emissions. Overall, the characteristics of aluminum, including its lightweight nature, durability, resistance to corrosion, thermal and acoustic insulation properties, design flexibility, and sustainability, make it highly suitable for manufacturing architectural wall panels.

- Q: What precautions should be taken to ensure safety while installing aluminum sheets?

- <p>When installing aluminum sheets, safety measures include wearing appropriate personal protective equipment (PPE) such as gloves, safety glasses, and hard hats. Ensure the work area is clear of debris and any tripping hazards. Use ladders and scaffolding that are in good condition and set up correctly. Always have a spotter when lifting heavy sheets and use proper lifting techniques to avoid back injuries. Keep hands and feet away from edges and corners to prevent cuts. Ensure all tools are in good working order and use them correctly. Follow all manufacturer's guidelines for installation and adhere to local safety regulations.</p>

- Q: Is it possible to utilize aluminum sheets in the construction of furniture?

- <p>Yes, aluminum sheets can be used for furniture. They are lightweight, durable, and resistant to corrosion, making them suitable for various types of furniture such as outdoor furniture, tables, chairs, and shelving. Aluminum's strength and flexibility allow for creative designs and easy maintenance. Additionally, it is a sustainable material that can be recycled, contributing to environmental sustainability.</p>

- Q: i m not sure if aluminum hydroxide is a acid or base. if somebody could help me, i will really appreciate.If u can could you also tell me if im wrong or right about the following substances:- pepsi cola is acid- vinegar is a base- ammonia is a base- aluminum hydroxyde is ?thank u for your help.

- anything hydroxide is basic (it refers to the OH-) pepsi has citric acid in it, therefore it is an acid vinegar is acetic acid, and is therefore acidic ammonia is certainly a base and aluminum hydroxide is basic (see above)

- Q: This question asks for guidance on selecting aluminum sheets based on their intended use, implying a need for criteria or factors to consider when making such a choice.

- <p>When choosing aluminum sheets for different purposes, consider the following factors: 1) Thickness: Depending on the strength and durability required, select the appropriate thickness. 2) Alloy Type: Different alloys have varying properties; for instance, 1100 series is purest and softest, while 6000 series offers high strength. 3) Surface Finish: Choose between mill finish, anodized, or coated finishes based on aesthetic and functional needs. 4) Temper: This refers to the hardness and strength, with options like O (annealed), H14 (strain hardened), and T6 (solution heat treated). 5) Application: Consider the specific use, such as construction, automotive, or aerospace, as each may require specific properties. Always consult with a supplier or engineer for advice tailored to your project's needs.</p>

- Q: This question asks for a list of various types of fasteners that can be used to secure aluminum windows to their frames.

- <p>There are several types of fasteners used for attaching aluminum windows to frames, including: 1. Screws: Commonly used for their secure hold and ease of installation. 2. Nails: Quick to use but may not provide the same level of security as screws. 3. Adhesives: Can be used for a more permanent bond, especially in certain applications. 4. Clips and brackets: Used for a more visible, decorative attachment. 5. Rivets: Provide a strong, permanent connection but are not easily removable. 6. Dowels and pins: Used for a more traditional or decorative join. 7. Structural glazing systems: Employ silicone or other sealants to bond the window to the frame. Each type of fastener has its own advantages and is chosen based on the specific requirements of the project, such as load-bearing needs, aesthetic considerations, and the desired level of permanence.</p>

- Q: What are the different methods of surface texturing aluminum sheets?

- There are several methods of surface texturing aluminum sheets, each with its unique advantages and applications. 1. Mechanical Texturing: This method involves the use of mechanical tools or processes to create patterns or textures on the surface of aluminum sheets. Examples include brushing, sanding, or embossing. Mechanical texturing is commonly used to create a matte or brushed finish on aluminum sheets, which enhances their aesthetic appeal and hides surface imperfections. 2. Chemical Texturing: Chemical texturing involves the use of chemicals to etch the surface of aluminum sheets and create unique patterns or textures. Acid etching is a common chemical texturing method that involves immersing the aluminum sheet in an acid solution to selectively dissolve the surface and create a textured surface. Chemical texturing is often used to improve the adhesive properties of aluminum sheets, making them suitable for bonding or coating applications. 3. Anodizing: Anodizing is an electrochemical process that creates a controlled oxide layer on the surface of aluminum sheets. This process can be used to create a variety of surface textures, ranging from a smooth, glossy finish to a rough, matte finish. Anodizing not only provides a textured appearance but also enhances the corrosion resistance and durability of the aluminum sheet. It is commonly used in architectural applications, consumer products, and automotive parts. 4. Laser Texturing: Laser texturing involves the use of laser technology to create precise and intricate patterns or textures on the surface of aluminum sheets. Laser beams can be precisely controlled to remove material or modify the surface in a desired pattern, allowing for highly customizable and detailed textures. Laser texturing is often used in decorative or high-end applications, such as jewelry, signage, or interior design. Each method of surface texturing aluminum sheets offers unique benefits and is suitable for different applications. The choice of texturing method depends on factors such as the desired texture, durability requirements, aesthetic preferences, and intended use of the aluminum sheets.

Send your message to us

Pvdf Coated Direct Rolled Aluminum Circle for Food Cookware

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords