PVC Waterproofing Sheets with Polyester Reinforcement

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC Waterproofing Sheets with Polyester Reinforcement

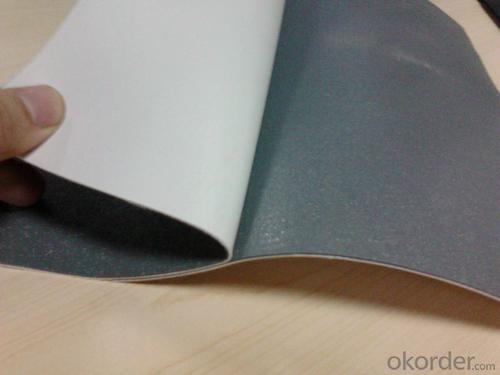

Product Description of PVC Waterproofing Sheets with Polyester Reinforcement:

PVC Membrane Waterproof /Waterproofing membrane For Roof is a new polymer waterproof membrane. The PVC Membrane Waterproof /Waterproofing membrane For Roof raw material is polyvinyl chloride resin, mixed with plasticizer, filler, antioxygen, ultraviolet absorber and other auxiliaries.

Thickness: 1.2mm/1.5mm/1.8mm/2.0mm

Width:2050mm

Length:20m( Special specifications can be customized)

Size: 2.05mx20m

Color: white/grey, or any other colors.

Features of PVC Waterproofing Sheets with Polyester Reinforcement:

1. Excellent anti-aging property.

2. Puncture- resistant.

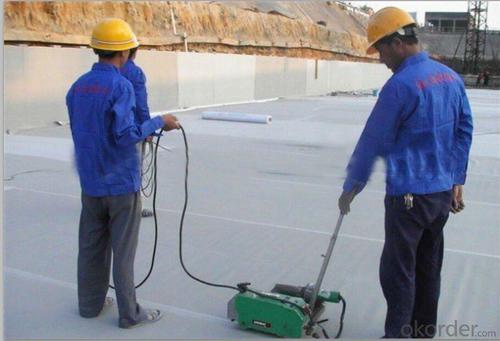

3. Welding construction,

4. High tensile strength, good elongation, good dimensional stability.

5. Good plasticity.

6. It has self-extinguishing from fire property.

7. Materials surface is smooth, fast color, stain resistance.

8. More wide, Wastage become less when being used.

Classification of PVC Waterproofing Sheets with Polyester Reinforcement:

1. N: Homogeneous PVC membrane

2. L: PVC membrane with fabric backing

3. W: Reinforced PVC membrane

Advantage of PVC Waterproofing Sheets with Polyester Reinforcement:

1.) Mixing automation. Apply automatic temperature control automatic time control and automatic feed control.

2.) Extrusion equipment uses twin screw coextrusion. Screw temperature uses computer automatic temperature control system.

3.) Handpiece uses large width didhead extrusion equipment.

4.) Sophisticated three-roller calender equipment. The space between equiment is controlled by automation system.

Technical Data of PVC Waterproofing Sheets with Polyester Reinforcement:

No. | Item | Model Ⅱ | |

1 | Tensile Strength Mpa ≥ | 12.0 | |

2 | Elongation at break% ≥ | 250 | |

3 | Shrinkage rate % ≤ | 2.0 | |

4 | Flexibility at low temperature | No crackle at -25oC | |

5 | Water tightness | Watertight | |

6 | Puncture resistance | Watertight | |

7 | Heat aging treatment | Appearance | Free from bubble, crack, cohesion and void |

Change rate of tensile strength % | +20oC | ||

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

8 | Chemical corrosion resistance | Change rate of tensile strength % | +20 |

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

9 | Artificial weathering | Change rate of tensile strength % | +20 |

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

Application of PVC Waterproofing Sheets with Polyester Reinforcement:

1) All kinds of roofs, such as steel structure roof, planted roof etc.

2) Underground engineering, such as building basement, subways, tunnels, air raid shelter, etc.

3) Other projects like artificial lake, dam, water reservoir, grain storehouse, etc.

Images of PVC Waterproofing Sheets with Polyester Reinforcement:

FAQ:

1. Can you produce 4m width?

Yes, no problem for us. We have four bases in China, largest one in this field.

2. How many quantity in one 20'' container for 1.2mm and 1.5mm?

480rolls, 11520m2 for 1.2mm and 400rolls, 9600m2 for 1.5mm

3. Can you provide free samples?

Yes, our samples are free, but express fees usually on buyer's account.

- Q: Why the roof of the waterproof membrane and insulation rock wool board to do between the isolation layer?

- 3, in the insulation layer on whether to protect the isolation layer according to the construction of the insulation layer on the destruction of the role of the waterproof layer. Since the waterproofing membrane has been completed construction, indicating that the flatness has reached a higher demand, and the insulation layer of the grass-roots flatness requirements do not exceed the requirements of the web paving, so waterproof surface without leveling layer, but may need to do protection Isolation layer.

- Q: Can waterproofing membranes be used on rooftop terraces?

- Yes, waterproofing membranes can indeed be used on rooftop terraces. In fact, they are often utilized to protect the structural integrity of the terrace and prevent water damage to the underlying structure. Rooftop terraces are exposed to various weather conditions, including rain, snow, and UV rays, which can lead to leaks and deterioration. Waterproofing membranes act as a barrier, preventing water from seeping through the surface and causing damage. These membranes are specifically designed for outdoor use and can withstand the harsh conditions typically found on rooftops. They are available in various materials such as modified bitumen, EPDM (ethylene propylene diene terpolymer), and PVC (polyvinyl chloride), allowing for flexibility in choosing the most suitable option for a specific terrace. Additionally, waterproofing membranes can be installed under various types of terrace finishes, including pavers, tiles, and decking, providing a versatile solution for different design preferences. Overall, the use of waterproofing membranes is highly recommended for rooftop terraces to ensure their longevity, durability, and resistance to water-related issues.

- Q: Is a waterproofing membrane resistant to hydrocarbons or oil spills?

- Yes, a waterproofing membrane is typically resistant to hydrocarbons or oil spills. Waterproofing membranes are designed to create a barrier that prevents water penetration and moisture damage to the underlying surfaces. These membranes are often made from materials such as modified bitumen, polyurethane, or PVC, which have excellent resistance to various chemicals, including hydrocarbons and oil. This resistance ensures that the membrane remains intact and effective even when exposed to oil spills or hydrocarbon-based substances. However, it is essential to note that the specific resistance may vary depending on the type and quality of the waterproofing membrane used. Therefore, it is crucial to select a membrane that is specifically engineered to withstand the intended environment and potential chemical exposures.

- Q: Can a waterproofing membrane be used on metal block surfaces?

- Metal block surfaces can indeed benefit from the use of a waterproofing membrane. These membranes are specifically designed to form a barrier against water and moisture, and they are versatile enough to be applied to various types of surfaces, including metal. By adhering to the metal surface, the membrane creates a protective layer that not only prevents water infiltration but also safeguards the metal against rust and corrosion. However, it is crucial to guarantee that the metal surface is thoroughly cleaned, dried, and appropriately prepared before the application of the waterproofing membrane. This preparation ensures optimal adhesion and effectiveness. For specific instructions on using a waterproofing membrane on metal block surfaces, it is highly recommended to consult a professional or refer to the manufacturer's guidelines.

- Q: Can a waterproofing membrane be used on roofs with rooftop gardens?

- Yes, a waterproofing membrane can be used on roofs with rooftop gardens. The membrane serves as a protective layer that prevents water from seeping into the underlying structure, ensuring that the rooftop garden remains dry and well-maintained.

- Q: Is the asphalt waterproofing membrane facing the side?

- 3, Summary: normal self-adhesive waterproof, the bottom of the membrane bonding surface facing the surface, the wall toward the back of the water; pre-shop anti-stick, the bottom of the membrane surface facing the back surface, wall is also facing the water.

- Q: Is a waterproofing membrane resistant to UV rays?

- Indeed, UV rays can be resisted by a waterproofing membrane. Numerous waterproofing membranes are specifically designed and produced with additional substances that provide safeguard against UV rays. These substances aid in preventing the membrane from deteriorating and losing its waterproofing properties when it comes in contact with sunlight. The resistance to UV rays is a crucial characteristic in waterproofing membranes, particularly for situations where the membrane will be exposed to direct sunlight for extended periods, such as rooftops or outdoor structures. However, it is essential to acknowledge that the degree of UV resistance may vary depending on the specific type and brand of waterproofing membrane. Consequently, it is always advisable to examine the product specifications and seek guidance from the manufacturer to ensure that the chosen membrane offers the desired level of UV resistance for the intended application.

- Q: Can a waterproofing membrane be used in conjunction with green building practices?

- Certainly, a waterproofing membrane can be utilized alongside green building practices. In actuality, integrating a waterproofing membrane into the construction of a green building can greatly enhance its overall sustainability and efficiency. One of the fundamental principles of green building practices is to maximize energy efficiency and decrease the environmental impact of a structure. By installing a waterproofing membrane, the building's outer covering can be shielded from moisture intrusion, thereby preventing water damage and potential mold growth. This, in turn, aids in preserving the structural integrity of the building, reducing the necessity for costly repairs and replacements, which can consume resources and generate waste. Moreover, a waterproofing membrane can contribute to improved indoor air quality. By preventing water infiltration, it assists in creating a dry and healthy living or working environment, minimizing the risk of respiratory problems and other health issues associated with dampness. Furthermore, a waterproofing membrane can enhance the energy efficiency of a building. By preventing water from seeping into the walls or foundation, it lessens the potential for heat loss through moisture evaporation, thus reducing the energy required for heating and cooling. This can lead to decreased energy consumption and lower carbon emissions, aligning with the objectives of green building practices. However, it is crucial to select a waterproofing membrane that is environmentally friendly and compliant with green building standards. Seek out membranes that are crafted from recycled or sustainable materials and possess low VOC (volatile organic compound) content. Additionally, consider opting for a membrane that is designed for longevity and durability, as this can further minimize the environmental impact by reducing the need for replacement over time. In conclusion, a waterproofing membrane can be an invaluable addition to any green building endeavor. It serves to safeguard the building envelope, enhance indoor air quality, and improve energy efficiency. By choosing an environmentally friendly membrane, the overall sustainability of the building can be further enhanced.

- Q: Can a waterproofing membrane be used on precast stone surfaces?

- Indeed, the utilization of a waterproofing membrane is viable on precast stone surfaces. Similar to all other concrete or masonry surfaces, precast stone surfaces are prone to water infiltration, which may lead to long-term damage. By applying a waterproofing membrane onto the precast stone surface, one can effectively prevent water penetration and shield the stone from moisture-related problems such as cracking, spalling, and efflorescence. This membrane establishes a barrier that hinders water seepage into the stone while still permitting it to respire and release any trapped moisture. Hence, it is crucial to select a waterproofing membrane that is compatible with the precast stone material and meticulously adhere to the manufacturer's instructions for proper application.

- Q: Can a waterproofing membrane be used in conjunction with green building practices?

- Certainly, a waterproofing membrane can be utilized alongside green building practices. In actuality, integrating a waterproofing membrane into the construction of a green building can greatly enhance its overall sustainability and efficiency. One of the fundamental principles of green building practices is to maximize energy efficiency and decrease the environmental impact of a structure. By installing a waterproofing membrane, the building's outer covering can be shielded from moisture intrusion, thereby preventing water damage and potential mold growth. This, in turn, aids in preserving the structural integrity of the building, reducing the necessity for costly repairs and replacements, which can consume resources and generate waste. Moreover, a waterproofing membrane can contribute to improved indoor air quality. By preventing water infiltration, it assists in creating a dry and healthy living or working environment, minimizing the risk of respiratory problems and other health issues associated with dampness. Furthermore, a waterproofing membrane can enhance the energy efficiency of a building. By preventing water from seeping into the walls or foundation, it lessens the potential for heat loss through moisture evaporation, thus reducing the energy required for heating and cooling. This can lead to decreased energy consumption and lower carbon emissions, aligning with the objectives of green building practices. However, it is crucial to select a waterproofing membrane that is environmentally friendly and compliant with green building standards. Seek out membranes that are crafted from recycled or sustainable materials and possess low VOC (volatile organic compound) content. Additionally, consider opting for a membrane that is designed for longevity and durability, as this can further minimize the environmental impact by reducing the need for replacement over time. In conclusion, a waterproofing membrane can be an invaluable addition to any green building endeavor. It serves to safeguard the building envelope, enhance indoor air quality, and improve energy efficiency. By choosing an environmentally friendly membrane, the overall sustainability of the building can be further enhanced.

Send your message to us

PVC Waterproofing Sheets with Polyester Reinforcement

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords