PVC Waterproofing Membrane in customized Thickness

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC Waterproofing Membrane in customized Thickness

Product Description of PVC Waterproofing Membrane in customized Thickness:

PVC Membrane Waterproof /Waterproofing membrane For Roof is a new polymer waterproof membrane. The PVC Membrane Waterproof /Waterproofing membrane For Roof raw material is polyvinyl chloride resin, mixed with plasticizer, filler, antioxygen, ultraviolet absorber and other auxiliaries.

Thickness: 1.2mm/1.5mm/1.8mm/2.0mm

Width:2050mm

Length:20m( Special specifications can be customized)

Size: 2.05mx20m

Color: white/grey, or any other colors.

Features of PVC Waterproofing Membrane in customized Thickness:

1. Excellent aging resistance. Service life of roofing material is over 20 years; service life of underground material is over 50 years.

2. Root resistant penetration, specially used on planting roofings.

3. Welding installation. Joints are solid and environment friendly, no pollution.

4. High tensile strength, good elongation and dimensional stability.

5. Good plasticity, easy and suitable for details installation.

6. Fireproof. Fire extinguished out of the ignition resource.

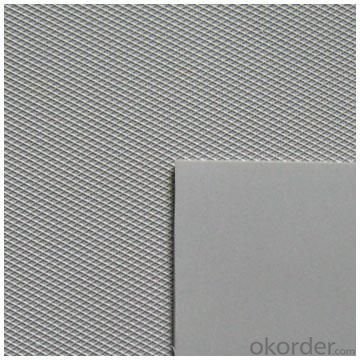

7. Surface is smooth, no fading and dirty resistant.

8. Width is over 2m. Construction wastage is small, more economical.

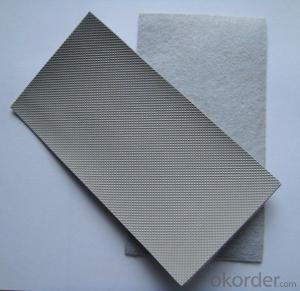

Classification of PVC Waterproofing Membrane in customized Thickness:

1. N: Homogeneous PVC membrane

2. L: PVC membrane with fabric backing

3. W: Reinforced PVC membrane

Advantage of PVC Waterproofing Membrane in customized Thickness:

1.) Mixing automation. Apply automatic temperature control automatic time control and automatic feed control.

2.) Extrusion equipment uses twin screw coextrusion. Screw temperature uses computer automatic temperature control system.

3.) Handpiece uses large width didhead extrusion equipment.

4.) Sophisticated three-roller calender equipment. The space between equiment is controlled by automation system.

Technical Data of PVC Waterproofing Membrane in customized Thickness:

No. | Item | Model Ⅱ | |

1 | Tensile Strength Mpa ≥ | 12.0 | |

2 | Elongation at break% ≥ | 250 | |

3 | Shrinkage rate % ≤ | 2.0 | |

4 | Flexibility at low temperature | No crackle at -25oC | |

5 | Water tightness | Watertight | |

6 | Puncture resistance | Watertight | |

7 | Heat aging treatment | Appearance | Free from bubble, crack, cohesion and void |

Change rate of tensile strength % | +20oC | ||

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

8 | Chemical corrosion resistance | Change rate of tensile strength % | +20 |

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

9 | Artificial weathering | Change rate of tensile strength % | +20 |

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

Application of PVC Waterproofing Membrane in customized Thickness:

PVC waterproof membrane forms an effective barrier to liquid water or water vapor in the steel structure for industrial and civil engineering, underground engineering, such as subway, bridges , tunnel, water pools, shelter, grain depot, land filling and subwayProducts display.

Images of PVC Waterproofing Membrane in customized Thickness:

FAQ:

1. Can you produce 4m width?

Yes, no problem for us. We have four bases in China, largest one in this field.

2. How many quantity in one 20'' container for 1.2mm and 1.5mm?

480rolls, 11520m2 for 1.2mm and 400rolls, 9600m2 for 1.5mm

3. Can you provide free samples?

Yes, our samples are free, but express fees usually on buyer's account.

- Q: Can a waterproofing membrane be used on PVC roofs?

- Yes, a waterproofing membrane can be used on PVC roofs. PVC (polyvinyl chloride) roofs are commonly used in commercial and residential buildings due to their durability and resistance to weathering. However, like any roofing material, PVC roofs can develop leaks or cracks over time. Applying a waterproofing membrane can help protect the roof from water infiltration and extend its lifespan. Waterproofing membranes, such as EPDM (ethylene propylene diene terpolymer) or TPO (thermoplastic olefin), are flexible and can adhere to the PVC surface, creating a seamless and watertight barrier. It is important to ensure that the waterproofing membrane is compatible with PVC roofs and follow the manufacturer's instructions for proper installation. Regular maintenance and inspections are also recommended to identify and address any potential issues before they escalate.

- Q: Can waterproofing membranes be used on rooftop terraces?

- Yes, waterproofing membranes can indeed be used on rooftop terraces. In fact, they are often utilized to protect the structural integrity of the terrace and prevent water damage to the underlying structure. Rooftop terraces are exposed to various weather conditions, including rain, snow, and UV rays, which can lead to leaks and deterioration. Waterproofing membranes act as a barrier, preventing water from seeping through the surface and causing damage. These membranes are specifically designed for outdoor use and can withstand the harsh conditions typically found on rooftops. They are available in various materials such as modified bitumen, EPDM (ethylene propylene diene terpolymer), and PVC (polyvinyl chloride), allowing for flexibility in choosing the most suitable option for a specific terrace. Additionally, waterproofing membranes can be installed under various types of terrace finishes, including pavers, tiles, and decking, providing a versatile solution for different design preferences. Overall, the use of waterproofing membranes is highly recommended for rooftop terraces to ensure their longevity, durability, and resistance to water-related issues.

- Q: DTM.E polyester composite waterproofing membrane, cheaper than the asphalt membrane?

- The coil with polyethylene, EVA or TPO as the main material, the upper and lower surface of the membrane using a special process non-woven composite, the construction of the use of Ou Xi Jianke special adhesive, membrane and cement material to form a close waterproof layer, To achieve the perfect waterproof effect.

- Q: Can a waterproofing membrane be used for wastewater treatment plants or sewage facilities?

- Yes, a waterproofing membrane can be used for wastewater treatment plants or sewage facilities. These facilities often require protection against water infiltration and leakage due to the presence of large amounts of water and potentially corrosive substances. A waterproofing membrane is a versatile solution that can provide a barrier against water penetration, helping to prevent damage to the structure and ensure the proper functioning of the facility. It can be applied to various areas such as walls, floors, roofs, and tanks, helping to maintain a watertight environment and prolong the lifespan of the facility. Additionally, some waterproofing membranes are specifically designed to withstand harsh chemicals, making them suitable for wastewater treatment plants and sewage facilities where corrosive substances may be present.

- Q: Can a waterproofing membrane be used for water fountains or decorative features?

- Yes, a waterproofing membrane can be used for water fountains or decorative features. Waterproofing membranes are designed to provide a protective barrier against water penetration and can be applied to various surfaces, including those used in water fountains and decorative features. These membranes are typically made from materials such as rubber, bitumen, or liquid-applied coatings, which offer excellent waterproofing properties. By applying a waterproofing membrane, you can ensure that water does not seep into the underlying structure and cause damage. This is particularly important for water fountains and decorative features as they involve constant exposure to water. Additionally, waterproofing membranes can also help prevent leaks, cracks, and other potential issues that may arise from water exposure, thus prolonging the lifespan of the fountain or decorative feature.

- Q: Can a waterproofing membrane be used for a basement floor slab?

- A basement floor slab can indeed benefit from the use of a waterproofing membrane. Its purpose is to hinder the infiltration of water and moisture into the surface to which it is applied. This solution is highly effective in shielding basement floor slabs against potential water damage. By applying a waterproofing membrane to the basement floor slab, you can establish a barrier that effectively obstructs water from penetrating, thus diminishing the likelihood of water damage, mold growth, and structural problems. Moreover, a waterproofing membrane can also function as a vapor barrier, preventing moisture from rising through the slab and causing issues like dampness or excessive humidity levels in the basement. All in all, selecting a waterproofing membrane for a basement floor slab is a wise decision that guarantees long-term durability and protection for the basement.

- Q: Can a waterproofing membrane be used for an industrial facility floor?

- Indeed, the utilization of a waterproofing membrane on an industrial facility floor is feasible. In the realm of industrial environments, waterproofing membranes are frequently employed as a means of safeguarding floors against water-related harm and the infiltration of moisture into the concrete or substrate. These membranes are meticulously engineered to establish a seamless and impenetrable barrier capable of withstanding the rigors of heavy foot traffic, industrial machinery, and chemical spills. Furthermore, they offer supplementary advantages such as resistance to the growth of mold and mildew, heightened durability, and simplified maintenance. Nevertheless, it is imperative to select a waterproofing membrane specifically tailored for industrial applications and diligently adhere to the manufacturer's guidelines regarding proper installation and maintenance.

- Q: Can waterproofing membranes be used on utility tunnels?

- Utility tunnels, which are often exposed to moisture and water infiltration, can benefit from the use of waterproofing membranes. These membranes serve to safeguard the tunnel structure against water damage and ensure its longevity. Their purpose is to establish a barrier between the structure and its surroundings, effectively halting the seepage of water into the tunnel. Typically crafted from materials like bitumen or synthetic polymers, these membranes possess remarkable resistance against water penetration. By applying them to the walls, floors, and ceilings of utility tunnels, they provide comprehensive protection against water-related issues, including leaks, cracks, and deterioration. Furthermore, waterproofing membranes also play a vital role in upholding the integrity of utility tunnels by thwarting the influx of harmful substances such as chemicals or pollutants. In conclusion, the application of waterproofing membranes to utility tunnels represents a highly effective means of guaranteeing their long-term durability and functionality.

- Q: Can a waterproofing membrane be used on roofs?

- Yes, a waterproofing membrane can be used on roofs. Waterproofing membranes are often applied to roofs to provide a protective barrier against water penetration and ensure the roof remains watertight.

- Q: Can a waterproofing membrane be used for a planter box waterproofing?

- Planter box waterproofing can be achieved by utilizing a waterproofing membrane. This specific type of membrane is designed to establish a barrier against water and moisture, effectively prohibiting their penetration through the surface it is applied on. Consequently, it serves as an excellent option for safeguarding the integrity of the planter box and preventing water-related harm. By applying the membrane to the interior of the box, a tight seal is formed, effectively preventing water leakage and damage to surrounding surfaces. Furthermore, the utilization of a waterproofing membrane aids in prolonging the lifespan of the planter box by curbing the growth of mold or mildew, which can be triggered by excessive moisture. In conclusion, opting for a waterproofing membrane for planter box waterproofing is a pragmatic and efficient approach to ensure the long-lasting durability of the structure.

Send your message to us

PVC Waterproofing Membrane in customized Thickness

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords