PVC Roofing Waterproofing Membrane with UV Resistance

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

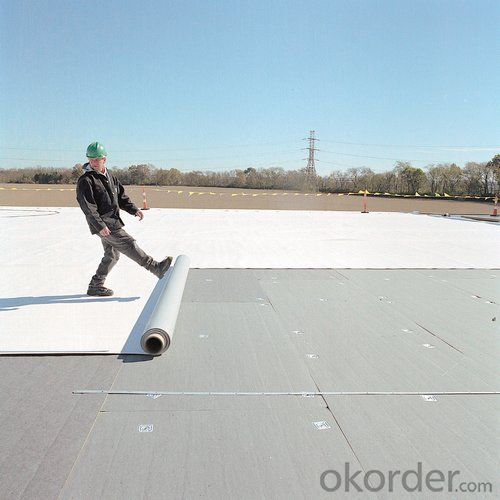

PVC roofing waterproof membrane with UV resistance

PVC membrane can be used for waterproofing on the steel roof, walking roof , planting roof, tunnel, basement, etc.

PVC membrane introduction:

Polyvinyl Chloride (PVC) membrane waterproof membrane is a kind of polymer compound

waterproof membrane compound of polyvinyl chloride colophony, plasticizer, stabilizing agent

,ultraviolet radiation(UV) resistance agent, all kinds of dyes and other agent.

1) Thickness: 0.3mm-2.0mm

2) Color: gray, green, blue

3.) Width: 2.0m

Polyvinyl chloride the pvc waterproofing plastic membrane is a kind of excellent performance of polymer waterproof material,PVC resin as the main raw material,add all kinds of special additive and anti-aging composition,the use of advanced equipment and advanced technology extrusion rolling is made.The product has the tensile strength and elongation high shrinkage of small,low temperature soft good,long life and other advantages, the products wide 1.2m to 3.0m, the thickness of 0.8-2.0 mm(special specifications can be customized),stable performance,reliable quality,construction is convenient.

Application Scope

The products are widely used in all kinds of civil construction,subway,tunnel,water conservancy,landfill site,chemical industry,metallurgy and other areas of waterproof seepage control,corrosion engineering.

Product Category

Single composite PVC waterproof materials

Double composite PVC waterproof board

Seperate PVC waterproof board

Some sticky type PVC waterproof materials

FAQ of PVC Waterproofing Membrane

a.Can we get some samples before place order?

Answer: We can send the free samples to you by freight collect.

b.How many years can your PVC membrane guarantee?

Answer: We will guarantee the quality for 5 years at least.

c.Which countries you ever export the product?

Answer: We export the PVC membrane to South Africa, Middle east and even European countries.

- Q: Can a waterproofing membrane be used for a balcony deck coating?

- Yes, a waterproofing membrane can be used for a balcony deck coating. Waterproofing membranes are designed to create a protective barrier that prevents water penetration, making them an ideal choice for balcony decks. By applying a waterproofing membrane to the deck surface, you can prevent water damage, such as leaks, cracks, and deterioration, which can lead to costly repairs. Additionally, waterproofing membranes can also protect the underlying structure of the balcony from moisture damage, extending its lifespan. It is important to choose a high-quality waterproofing membrane that is specifically designed for outdoor use and can withstand exposure to harsh weather conditions.

- Q: Can a waterproofing membrane be used on wood block surfaces?

- Yes, a waterproofing membrane can be used on wood block surfaces. The membrane acts as a protective barrier, preventing water penetration and potential damage to the wood. It is a common practice to use waterproofing membranes on wood block surfaces in order to enhance their durability and longevity.

- Q: Can a waterproofing membrane be used in elevator pits or sump pits?

- Certainly! Below is a rewritten version of the passage: Indeed, elevator pits or sump pits can benefit from the utilization of a waterproofing membrane. These pits are prone to water infiltration, but the application of a waterproofing membrane can effectively prevent water seepage. By acting as a barrier, the membrane stops any water from entering the pit and causing harm to the elevator or pumping system. Consequently, this safeguards the longevity and integrity of the elevator or pump. Moreover, the waterproofing membrane also safeguards the surrounding structures from water damage. Thus, it is crucial to select a suitable waterproofing membrane that is specifically designed for below-ground applications and possesses the necessary properties to withstand the unique conditions within an elevator or sump pit.

- Q: Are waterproofing membranes suitable for balconies and terraces?

- Yes, waterproofing membranes are suitable for balconies and terraces as they provide an effective barrier against water infiltration, protecting the underlying structure from potential damage caused by moisture.

- Q: Do waterproofing membranes require maintenance?

- Yes, waterproofing membranes do require maintenance. While they are designed to provide long-lasting protection against water damage, regular maintenance is necessary to ensure their effectiveness. Over time, the membrane may develop cracks, tears, or other forms of damage that can compromise its waterproofing capabilities. Additionally, debris, dirt, and other substances can accumulate on the membrane's surface, obstructing drainage and causing water to pool. Therefore, it is important to inspect the membrane regularly and address any issues promptly. This may involve cleaning the surface, patching or replacing damaged sections, and resealing seams or joints to maintain a watertight barrier. Regular maintenance not only prolongs the lifespan of the waterproofing membrane but also helps prevent costly water damage to the underlying structure.

- Q: Can a waterproofing membrane be used on interior walls?

- Yes, a waterproofing membrane can be used on interior walls to prevent water infiltration and moisture damage.

- Q: What is the typical installation process for a waterproofing membrane?

- The typical installation process for a waterproofing membrane involves several steps. First, the surface to be waterproofed is cleaned and prepared, ensuring it is free from debris, dirt, and any loose materials. Next, a primer is applied to enhance the adhesion of the membrane. The waterproofing membrane is then unrolled and carefully laid onto the surface, ensuring it is aligned correctly. It is commonly secured using adhesive or mechanical fasteners. Any overlaps or joints are properly sealed using a compatible sealant or tape. Finally, a protective layer, such as a geotextile fabric or drainage board, may be added to enhance the durability and performance of the waterproofing system. Overall, the installation process requires attention to detail and adherence to manufacturer guidelines to ensure a successful waterproofing solution.

- Q: Can a waterproofing membrane be used on precast stone surfaces?

- Yes, a waterproofing membrane can be used on precast stone surfaces. Precast stone surfaces, like any other concrete or masonry surfaces, are susceptible to water infiltration, which can cause damage over time. Applying a waterproofing membrane on the precast stone surface can help prevent water penetration and protect the stone from moisture-related issues such as cracking, spalling, and efflorescence. The membrane forms a barrier that blocks water from seeping into the stone while still allowing it to breathe and release any trapped moisture. It is important to choose a waterproofing membrane that is compatible with the precast stone material and follow the manufacturer's instructions for proper application.

- Q: Are there any limitations to using a waterproofing membrane?

- Yes, there are some limitations to using a waterproofing membrane. One limitation is that the membrane can be punctured or damaged during installation, which can compromise its effectiveness. Additionally, waterproofing membranes may not be suitable for all types of surfaces or structures, and certain conditions such as extreme temperatures or excessive movement can affect their performance. Moreover, the lifespan of a waterproofing membrane can vary depending on factors like maintenance, exposure to UV rays, and overall wear and tear.

- Q: Can a waterproofing membrane be certified or approved by industry organizations?

- Yes, a waterproofing membrane can be certified or approved by industry organizations. There are various industry organizations and standards bodies that evaluate and certify building materials and products, including waterproofing membranes. These certifications or approvals ensure that the membrane meets specific quality and performance standards set by the industry. Industry organizations such as the International Organization for Standardization (ISO), Underwriters Laboratories (UL), and the American Society for Testing and Materials (ASTM) often provide certifications or approvals for waterproofing membranes. These certifications involve rigorous testing and evaluation of the membrane's physical properties, such as its ability to resist water penetration, durability, and compatibility with other building materials. Certifications or approvals from industry organizations provide assurance to consumers, architects, contractors, and building owners that the waterproofing membrane has undergone testing and meets recognized standards for quality and performance. They also help in building code compliance and may be required for certain projects. It is always advisable to look for waterproofing membranes that have been certified or approved by reputable industry organizations to ensure that you are using a reliable and effective product for your waterproofing needs.

Send your message to us

PVC Roofing Waterproofing Membrane with UV Resistance

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords