PVC Membrane Smooth with geotextile for Waterproof System

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC Membrane Smooth with geotextile for Waterproof System

Description Of PVC Membrane Smooth with geotextile forr Waterproof System:

1. PVC Membrane Smooth is made from PVC and poliester , which is for waterproofing of exposed and non-exposed applications.

2. PVC Membrane Smooth adopts the world-advanced equipment of cold feeding extrusion and continuous vulcanization technology.

Main Features of PVC Membrane Smooth with geotextile forWaterproof System:

1. Excellent physical and mechanical performance

2. High tearing resistance

3. Good deformation adaptability

Specifications of PVC Membrane Smooth with geotextile for for Waterproof System:

Material | PVC |

Size | 1.2m (width)*20m (length) or customized, weldable type 2.05m |

Thick | 1.2mm, 1.5mm, |

Type | Smooth |

Applications of PVC Membrane Smooth with geotextile forfor Waterproof System:

1.Roofs, Basement, Toilets

2. Industrial and civil building waterproofing

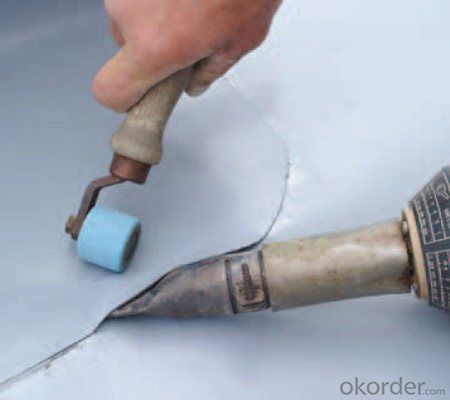

IMages of PVC Membrane Smooth with geotextile for Waterproof System:

FAQ:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating

.

2. How Many years experience do we have?

We have been exported to more than 15 countries in the past 10 years.

3. How long do we usually reply your request?

We always reply our customer within 12 hours.

- Q: Is a waterproofing membrane resistant to mold and mildew growth?

- Indeed, the resistance of a waterproofing membrane to the growth of mold and mildew stems from its specific design, which aims to establish a barrier against moisture infiltration. This impedes water seepage and the subsequent development of mold and mildew. Through the effective sealing of the area, these membranes eradicate the favorable conditions for the proliferation of mold and mildew, such as dampness and moisture. However, it is important to acknowledge that although the membrane itself exhibits resistance to mold and mildew growth, it does not guarantee absolute protection against these issues. Proper installation, regular maintenance, and ensuring adequate ventilation play pivotal roles in preventing the long-term growth of mold and mildew.

- Q: Can a waterproofing membrane be used for train platforms?

- Yes, a waterproofing membrane can be used for train platforms. Train platforms are exposed to various weather conditions, including rain and snow, which can cause water damage and deterioration over time. By installing a waterproofing membrane on the surface of the train platform, it creates a protective barrier that prevents water from seeping through and causing damage to the underlying structure. This helps to extend the lifespan of the platform, reduce maintenance costs, and ensure the safety of passengers and personnel. Additionally, a waterproofing membrane can also help to prevent the growth of mold and mildew, which can be detrimental to the health of individuals using the train platform. Overall, using a waterproofing membrane on train platforms is a practical and effective solution to protect against water damage and maintain the longevity of the infrastructure.

- Q: Can a waterproofing membrane be used for a roof?

- Yes, a waterproofing membrane can be used for a roof. Waterproofing membranes are specifically designed to provide a barrier against water penetration, making them an ideal choice for protecting roofs from leaks and water damage. They are durable, flexible, and can be applied to various types of roofs, including flat and sloped surfaces.

- Q: Are waterproofing membranes flexible?

- Waterproofing membranes, generally, exhibit flexibility. Their purpose is to be adaptable, enabling them to mold and adjust to the contours and shifts of the surfaces they are applied on. This adaptability effectively seals off any openings, fissures, or connections, effectively barring water infiltration into the foundation. Additionally, the elasticity of waterproofing membranes empowers them to endure the expansion and contraction caused by temperature fluctuations or structural shifts. In conclusion, the flexibility of waterproofing membranes is an essential attribute that guarantees their resilience and efficacy in safeguarding structures against water-related harm.

- Q: Can a waterproofing membrane be applied over existing coatings or sealants?

- Yes, a waterproofing membrane can be applied over existing coatings or sealants. However, it is important to ensure that the surface is properly prepared and any loose or damaged coatings or sealants are removed before applying the waterproofing membrane. This will ensure proper adhesion and effectiveness of the membrane. It is also recommended to consult the manufacturer's guidelines or seek professional advice to ensure compatibility between the existing coatings or sealants and the waterproofing membrane.

- Q: Can a waterproofing membrane be used on modified bitumen roofs?

- A waterproofing membrane is capable of being utilized on modified bitumen roofs. In fact, it is quite customary to apply a waterproofing membrane on top of modified bitumen roofs in order to provide an extra layer of defense against water infiltration. This is particularly crucial in regions where heavy rainfall occurs or where the roof is frequently exposed to water. The waterproofing membrane serves to seal any potential cracks or openings in the modified bitumen roofing system, thereby preventing water from penetrating and causing damage to the underlying structure. Moreover, the waterproofing membrane can also bolster the overall durability and longevity of the roof by shielding it from the detrimental effects of moisture.

- Q: Is a waterproofing membrane resistant to hydrochloric acid or other corrosive substances?

- Waterproofing membranes are designed to resist water penetration and are commonly used as a barrier against moisture. However, it is important to understand that the resistance of a waterproofing membrane to hydrochloric acid or other corrosive substances may vary depending on the specific material used. Some waterproofing membranes, like those made from bituminous or rubberized asphalt materials, have a higher resistance to chemicals such as hydrochloric acid. These membranes are often utilized in industrial settings where exposure to corrosive substances is frequent. They are specifically engineered to endure the effects of these substances and offer long-lasting protection. On the contrary, other types of waterproofing membranes, such as those composed of polyvinyl chloride (PVC) or high-density polyethylene (HDPE), may have a lower resistance to corrosive substances like hydrochloric acid. These membranes are typically employed in less demanding applications where chemical exposure is not a significant concern. Regardless, it is essential to refer to the manufacturer's specifications and guidelines when assessing the resistance of a particular waterproofing membrane to hydrochloric acid or other corrosive substances. The manufacturer can provide detailed information on the membrane's chemical resistance properties and offer guidance on its suitability for specific applications involving corrosive substances.

- Q: Can a waterproofing membrane be used on drywall surfaces?

- Indeed, it is possible to utilize a waterproofing membrane on surfaces composed of drywall. Drywall, being a material with porosity, is prone to damage caused by moisture, particularly in areas that are inclined to high levels of humidity or exposure to water, such as bathrooms or basements. The application of a waterproofing membrane on drywall aids in the creation of a protective barrier against moisture, thereby preventing the infiltration of water and potential harm. This membrane can be implemented either as a liquid coating or as a sheet membrane directly applied onto the drywall surface. It is of utmost importance to adhere to the instructions provided by the manufacturer and guarantee a proper installation, as this will result in effective waterproofing and safeguard the drywall from issues associated with moisture, such as the growth of mold, mildew, and rot.

- Q: Are waterproofing membranes resistant to salt damage?

- Yes, waterproofing membranes are generally resistant to salt damage. They are designed to protect against moisture and other environmental factors, including saltwater. The membranes are specifically engineered to provide a barrier that prevents water and salts from infiltrating and causing damage to underlying structures.

- Q: Can a waterproofing membrane be used on planter boxes?

- Planter boxes can indeed benefit from the use of a waterproofing membrane. Typically employed to prevent water from seeping through surfaces, a waterproofing membrane safeguards the wood or other materials of the planter box from moisture damage. When applied to the interior, this membrane acts as a barrier, stopping water from infiltrating the material and potentially causing decay or rot. Consequently, the planter box's lifespan is prolonged, ensuring it remains in excellent condition for an extended period. Moreover, the waterproofing membrane aids in retaining moisture within the planter box, which proves advantageous for the growth of plants or flowers. Overall, the application of a waterproofing membrane enhances protection and durability for planter boxes.

Send your message to us

PVC Membrane Smooth with geotextile for Waterproof System

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords