PVC Coated Fiberglass Fabric for Electric Insulation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Fabric with Silicone Coated for Electric Insulation

Fiberglass Fabric Description

Silicone coated fiberglass fabric is a fiberglass cloth, which possesses the properties of temperature resistance, anti-corrosion, high strength and is coated with organic silicone rubber.

Fiberglass Fabric Specification

Thickness:0.2mm-5mm

Width:100cm-150cm

Color;grey/red/silver/black

Weight(coating):130gsm-2800gsm

Model No | FSD2030 | FSD2030 | FSD2050 | FSD2100 | |

High temperature resistant(°C) | ≤280 | ≤280 | ≤280 | ≤280 | |

Low temperature resistant(°C) | ≥-40 | ≥-40 | ≥-40 | ≥-40 | |

Tensile intensity (N/50mm) | Warp | ≥1750 | ≥1750 | ≥2500 | ≥3500 |

Weft | ≥1280 | ≥1280 | ≥2100 | ≥3000 | |

Inflating burst intensity(Mpa) | ≥2.0 | ≥2.0 | ≥2.2 | ≥2.6 | |

Peeling intensity(N/m) | ≥450 | ≥450 | ≥520 | ≥600 | |

Insulation (kv/mm) | 16 | 16 | 18 | 18 | |

Weight (g/m*m) | 550-650 | 550-650 | 750-800 | 1500-1800 | |

Width(mm) | 1000±20 | 1000±20 | 1000±20 | 1000±20 | |

Thickness(mm) | 0.3-0.4 | 0.3-0.4 | 0.05-0.55 | 1.0-1.1 | |

color | Silver-gray, gray, red | lucency | Silver-gray, gray, red | Black, gray, red | |

Fiberglass Fabric Features:

1, Good performance on resisting high temperature and low temperature, -40°C-280°C;

2, High strength;

3, Ozone, oxide, light and weather aging resistance;

4, High insulation: dielectric constant:3-3.2, breakdown voltage: 20-50KV/MM;

5, Chemical corrosion resistant, oil-proofing, waterproofing (washable)

Fiberglass Fabric Application:

It has been widely used in construction, electric insulation,

chemical industry, pipeline ductile conjunction, large generating

Corrosion proofing field, machinery, metallurgy, sealing and so on.

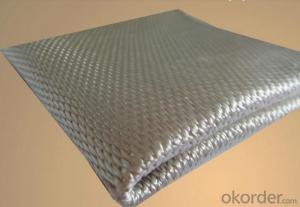

Product Show

FAQ

1.What are the characteristics of fiberglass fabric?

a)Outstanding temperature resistance(from -70°C to +260°C)

b)Excellent chemical resistance

c)Superior non-stick surface, easy to clean

d)High dielectric strength

e)Dimensional stability

f)Resistance to UV, IR and HF

g)Non-toxic

2.How many methods to weave the fabric?

Four methods to weave the fabric:

a).Plain weave: it can be used in electricity insulation materials and reinforced materials in industry, because of inseparable structure, plain and clear lines.

b).Twill weave: compared with plain weave, it is of high density, high intensity, with a soft and loose structural weave. It can be used in ordinary reinforced materials, filter materials, and painting cloth.

c) Satin weave: compared with plain weave and twill weave, it is of high density,high intensity, with a soft and loose structural weave with a good texture. It is applicable for use as a higher reinforced material in machinery.

d).Gauze weave: said lattice twist weave. It can be used in spread model curtain,resin reinforced emery wheel gray cloth and lattice embed belt.

3.Can you offer us some samples?

We are willing to offer our customers best product&service,if it's necessary we can send

you sample for test;also we welcome all you customer have a trial order.

- Q: Can fiberglass fabric be used for ducting?

- No, fiberglass fabric is not suitable for ducting as it lacks the necessary strength and durability required for such applications.

- Q: Emulsion rubber asphalt waterproof paint what brand is good

- Emulsified reclaimed rubber asphalt waterproof coating is suitable for industrial and civil buildings and non thermal insulation roof and basement, cave, cold storage, ground water and moisture and gas barrier, can also be used for the maintenance of the old asphalt roofing renovations and rigid self waterproofing, has a good protective effect on the surface of the concrete carbonization and weathering. During the construction, in order to achieve a good waterproof effect, emulsified reclaimed rubber asphalt waterproof coating to lining glass fiber cloth or synthetic fiber reinforced mat composed of waterproof layer, with caulking sealing material.

- Q: Can fiberglass fabric be used for heat-resistant gloves?

- Yes, fiberglass fabric can be used for heat-resistant gloves. Fiberglass has excellent thermal resistance properties, making it suitable for applications that require protection against high temperatures.

- Q: How is fiberglass fabric used in the production of composite materials?

- Fiberglass fabric is used in the production of composite materials as a reinforcement material. It is typically combined with resin to create a strong and lightweight composite structure. The fabric provides strength and durability to the composite material, making it suitable for various applications such as aerospace, automotive, and construction industries.

- Q: Can fiberglass fabric be used for insulation in cold storage facilities?

- Certainly, cold storage facilities can utilize fiberglass fabric as insulation. Renowned for its remarkable thermal insulation properties, fiberglass fabric proves to be a perfect selection for insulating cold storage facilities. It exhibits utmost effectiveness in impeding heat transfer, thereby aiding in maintaining the desired temperature within the facility. Furthermore, fiberglass fabric showcases resilience against moisture, mold, and mildew, prevailing issues in cold storage environments. This renders it an enduring and enduring option for insulation. Additionally, fiberglass fabric boasts effortless installation and adaptability to accommodate diverse shapes and sizes, guaranteeing comprehensive coverage and insulation throughout the facility.

- Q: Can fiberglass fabric be used for making curtains or blinds?

- Yes, fiberglass fabric can be used for making curtains or blinds. Fiberglass fabric is a versatile material that offers several advantages for window coverings. Firstly, it is highly durable and resistant to wear and tear, making it suitable for long-lasting curtains or blinds. Additionally, fiberglass fabric is flame-resistant, making it a safe option for window coverings. It is also light in weight, allowing for easy installation and operation. Moreover, fiberglass fabric is available in a wide range of colors and designs, offering flexibility in terms of aesthetics and matching the décor of a room. Lastly, it provides excellent light control and privacy, making it an ideal choice for curtains or blinds. Overall, fiberglass fabric is a practical and functional option for making curtains or blinds.

- Q: Can fiberglass fabrics be used for geotextile applications?

- Yes, fiberglass fabrics can be used for geotextile applications. Geotextiles are permeable fabrics used in civil engineering projects to stabilize soil, control erosion, and provide separation between different soil layers. While traditional geotextiles are typically made of synthetic materials like polyester or polypropylene, fiberglass fabrics can also be used effectively for these applications. Fiberglass fabrics offer numerous advantages for geotextile applications. Firstly, they have high tensile strength, meaning they can withstand significant loads and provide long-lasting stability. Additionally, fiberglass fabrics are resistant to chemicals, UV radiation, and biological degradation, making them suitable for various environmental conditions. Furthermore, fiberglass fabrics have excellent dimensional stability, meaning they will not shrink or expand significantly when exposed to moisture or temperature variations. This characteristic is crucial for maintaining the integrity and effectiveness of geotextiles over time. Another benefit of using fiberglass fabrics for geotextile applications is their excellent filtration properties. They can effectively prevent the migration of fine particles while allowing water to pass through, reducing the risk of soil erosion and maintaining water drainage. In conclusion, fiberglass fabrics can indeed be used for geotextile applications. Their high tensile strength, chemical resistance, dimensional stability, and filtration properties make them a suitable choice for various civil engineering projects where geotextiles are required.

- Q: What are the different fiberglass fabric weaves for electrical insulation?

- Some of the different fiberglass fabric weaves used for electrical insulation include plain weave, twill weave, satin weave, and leno weave. These weaves provide varying levels of strength, flexibility, and thermal resistance, making them suitable for different electrical insulation applications.

- Q: What are the weight options for fiberglass fabric?

- Fiberglass fabric, also known as glass fiber cloth, is available in a variety of weight options to suit different applications. The weight of fiberglass fabric is typically measured in ounces per square yard (oz/yd²) or grams per square meter (g/m²). The weight options for fiberglass fabric can range from as low as 0.5 oz/yd² (17 g/m²) to as high as 32 oz/yd² (1086 g/m²) or even more. The weight of fiberglass fabric determines its thickness, strength, and durability. Lighter weight fiberglass fabrics are often used for applications that require high flexibility and conformability, such as in the manufacturing of circuit boards or for reinforcing and repairing small parts. They are also commonly used in aviation and aerospace industries, where weight reduction is crucial. On the other hand, heavier weight fiberglass fabrics are typically used in applications that require higher strength and impact resistance. These can include boat building, automotive parts manufacturing, construction, and even in the production of bulletproof vests and armor. It is important to note that the weight of fiberglass fabric is just one factor to consider when choosing the right fabric for a specific application. Other factors like weave pattern, finish, and resin compatibility should also be taken into account to ensure optimal performance.

- Q: The difference between the projection screen and glass bead?

- A bead curtain is covered with a layer of fine glass beads, the gain value is relatively high, generally around 2.5. And low cost, generally used for business and education, but because of its material is not environmental protection, after a period of time is easy to yellow, and not easy to maintain, is slowly withdraw from the market.

Send your message to us

PVC Coated Fiberglass Fabric for Electric Insulation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords