Woven Fiberglass Fabric Continuous Stand Mat 2024 - China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

| Technique: | Chopped Strand Fiberglass Mat (CSM) | Dimensions: | 450gsm | Mat Type: | Continuous Filament Mat |

| Fiberglass Type: | E-Glass | Softness: | softness | Place of Origin: | Jiangxi, China (Mainland) |

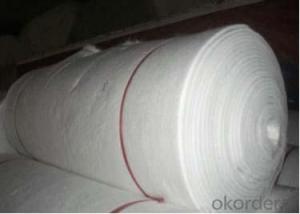

| Brand Name: | cnbm | Model Number: | 450gsm | color: | white |

| fiberglass type: | E glass | product: | e-glass powder chopped stand mats | binder: | powder or emulsion |

| width: | 1040 or 1270mm, as your requirement | weight: | 30 or 45kg/roll | paper tube diameter: | 90mm |

| outer diameter of roll: | 256mm | packing: | plastic film+carton box + pallet |

Packaging & Delivery

| Packaging Details: | plastic film+carton box + pallet |

| Delivery Detail: | 15-20days |

Specifications

1.e-glass powder chopped stand mats

2.binder:power or emulsion

3.width:1040mm or 1270mm

4.weight:450gsm

Picture

- Q: Silicone rubber and glass fiber cloth, capable of curing 300 degrees of adhesion method?

- Good electrical insulation properties. The electrical insulation properties of silicone rubber vulcanizates vary little when moisture, frequency, or temperature rise. The silicon dioxide produced after combustion is still an insulator. In addition, the molecular structure of silicone rubber is less carbon atoms, and does not use carbon black as filler, so it is not easy to scorch when arc discharge. Therefore, it is very reliable to use it in high pressure places

- Q: Can fiberglass fabrics be used for insulation in automotive engines?

- Fiberglass fabrics have the capability to insulate automotive engines, as they possess exceptional thermal insulation properties. This makes them suitable for situations where heat management is crucial, like in automotive engines. These fabrics demonstrate the ability to endure high temperatures without any degradation or loss of their insulating properties. They can be employed to cover various engine components, pipes, or any other areas that necessitate minimal heat transfer. Apart from their thermal insulation prowess, fiberglass fabrics also deliver additional advantages, including their lightweight nature, flexibility, and resistance to chemicals and fire. However, it is imperative to ensure proper installation and compatibility with the specific engine requirements in order to optimize the effectiveness and safety of fiberglass fabric insulation in automotive engines.

- Q: Can fiberglass fabric be used for filters?

- Yes, fiberglass fabric can be used for filters. Fiberglass fabric is known for its high strength and durability, as well as its ability to withstand high temperatures. These properties make it an excellent choice for various filtration applications. The tight weave of fiberglass fabric allows it to effectively trap and remove particles, making it suitable for filtering air, liquids, and even gases. Additionally, fiberglass fabric can be coated with various substances to enhance its filtration capabilities, such as adding a Teflon coating for oil and water repellency. Overall, fiberglass fabric is a versatile material that can be used effectively in filtration systems.

- Q: Is fiberglass fabric resistant to chemicals in food processing?

- Yes, fiberglass fabric is generally resistant to chemicals in food processing.

- Q: What are the environmental impacts of using fiberglass fabric?

- The environmental impacts of using fiberglass fabric include the extraction and processing of raw materials, which can contribute to air and water pollution. The production process also requires energy and can release greenhouse gases. Additionally, fiberglass fabric is not biodegradable and can contribute to waste accumulation. Proper disposal and recycling methods are crucial to minimize its environmental impact.

- Q: Can fiberglass fabric be used for making roller blinds?

- Certainly! Roller blinds can indeed be made using fiberglass fabric. The reason why fiberglass fabric is highly favored for roller blinds is because of its exceptional durability and strength. Its resistance to moisture and UV rays further enhances its suitability for both indoor and outdoor use. Moreover, the lightweight nature of fiberglass fabric enables effortless operation and maintenance of roller blinds. The fabric also offers a wide range of colors and patterns, granting flexibility in design choices. Overall, fiberglass fabric emerges as a trustworthy and pragmatic option for crafting roller blinds.

- Q: What are the different coating options available for fiberglass fabric?

- Fiberglass fabric can be coated with various options to enhance its properties and suitability for different applications. Here are some examples: 1. For heat resistance and high temperature endurance, silicone coating is an excellent choice. It also provides good chemical resistance, making it suitable for industries like aerospace, automotive, and insulation. 2. If you need a durable and flexible finish, polyurethane coating is the way to go. It offers abrasion resistance, waterproofing, and UV stability, making it commonly used in outdoor covers, tents, and awnings. 3. PTFE coating, known for its non-stick properties and resistance to chemicals, heat, and weathering, is ideal for applications requiring electrical insulation and low friction. It is often used in conveyor belts, release sheets, and insulation. 4. Acrylic coating enhances fiberglass fabric's durability and strength, providing a smooth finish. It also offers resistance to UV rays, mildew, and abrasion, making it suitable for marine covers, outdoor furniture, and bags. 5. Neoprene coating excels in resisting oil, chemicals, and weathering, and it offers good flame resistance and flexibility. It is commonly used in protective clothing, gloves, and industrial curtains. 6. Vinyl coating provides a waterproof and durable finish, with resistance to UV rays, abrasion, and chemicals. It is often used in outdoor furniture, truck covers, and pool liners. These examples represent just a few of the coating options available for fiberglass fabric. The specific choice depends on the application's requirements, such as heat resistance, chemical resistance, flexibility, and durability.

- Q: Can fiberglass fabric be used for making luggage?

- Yes, fiberglass fabric can be used for making luggage. Fiberglass fabric is known for its durability and strength, making it an ideal material for luggage that needs to withstand rough handling and frequent use. It is lightweight yet sturdy, which allows for easy maneuverability of the luggage while still providing protection for its contents. Additionally, fiberglass fabric is resistant to water and stains, making it a practical choice for luggage that may be exposed to various weather conditions. Overall, fiberglass fabric offers a reliable and long-lasting option for manufacturing luggage.

- Q: Can fiberglass fabric be used for insulation in construction projects?

- Yes, fiberglass fabric can be used for insulation in construction projects. Fiberglass fabric is made from woven glass fibers, which have excellent thermal insulation properties. It is commonly used as an insulation material in walls, roofs, and floors to prevent heat transfer and improve energy efficiency in buildings. The fabric is lightweight, flexible, and easy to install, making it a popular choice for construction projects. Additionally, fiberglass fabric is resistant to fire, moisture, and chemicals, making it a durable and long-lasting insulation material.

- Q: What is the moisture resistance of fiberglass fabric?

- The moisture resistance of fiberglass fabric is high. Fiberglass is known for its excellent resistance to moisture, making it a reliable choice for applications where exposure to water or humidity is a concern. The fabric's inherent properties, such as its non-absorbent nature and resistance to mold and mildew, contribute to its suitability for moisture-prone environments. Additionally, fiberglass fabric is often used in applications such as insulation, boat building, and roofing, where it is exposed to water or damp conditions, further highlighting its moisture resistance.

Send your message to us

Woven Fiberglass Fabric Continuous Stand Mat 2024 - China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords