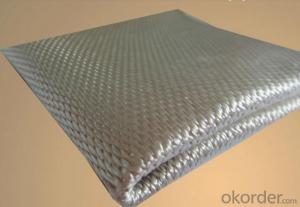

vermiculite coated fiberglass cloth high quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

vermiculite coated fiberglass cloth

Well-distributed, even tensile strength, good vertical performance.

Fast impregnation, good moulding property, easily removing air bubbles.

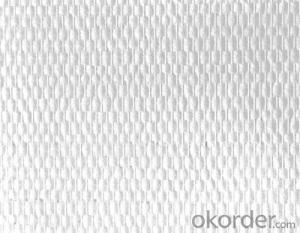

woven roving 800g /m2 non-alkali .

Products Introduction and Application

E-Glass woven roving is plain, biaxial fiberglass fabric that weaved with E-Glass direct roving. E-Glass Woven roving is compatible with unsaturated polyester, vinyl ester, epoxy and phenolic resins. It’s widely used in hand lay up, mold press, GRP forming process and robot processes to manufacture boats, vessels, plane, automobile parts, panels, storage tanks etc.

Products Features and Advantages

Well-distributed, even tensile strength, good vertical performance.

Fast impregnation, good moulding property, easily removing air bubbles.

High mechanical strength, less strength loss in wet condition.

Key Technical Data

Specs | Unit Mass (g/m2) | Breaking Strength≥N/2.5cm | Density | Weave | Roll Length (m) | Width (mm) | |||

Warp | Weft | Warp | Weft | ||||||

EWR400 | 400 | 1480 | 1380 | 3.5 | 3.3 | plain | 100-200 | 300-4000 | |

EWR600 | 600 | 1900 | 1800 | 3.0 | 2.5 | plain | 100-200 | 300-4000 | |

EWR800 | 800 | 2600 | 2350 | 2.0 | 2.0 | plain | 100-200 | 300-4000 | |

Packing Style

It is rolled on a paper core with a diameter of 100mm, then packed into a polyethylene bag, then outside packed into a separate cardboard box. Finally, the product can be ether shipped with cardboard box only or with pallet.

Storage

In dry and cool places. The best condition is with temperature between 15°C and 35°C, with a relative humidity between 30% -70%. Before use, please keep it in original package.

fibreglass Sample is free,freight is collect

- Q: Can fiberglass fabric be used for reinforcement in concrete pipes?

- Yes, fiberglass fabric can be used for reinforcement in concrete pipes. Fiberglass fabric is a strong and lightweight material that is resistant to corrosion, making it a suitable choice for reinforcing concrete structures, including pipes. It provides additional strength and durability to the concrete, enhancing its load-bearing capacity and reducing the risk of cracking or failure. Additionally, fiberglass fabric has good thermal and chemical resistance properties, which further contribute to its suitability for reinforcing concrete pipes.

- Q: Can fiberglass fabrics be used for insulation in HVAC ductwork?

- Indeed, insulation in HVAC ductwork can be achieved by employing fiberglass fabrics. The utilization of fiberglass fabrics in HVAC ductwork insulation is widespread, owing to their remarkable thermal attributes and fire resistance. By enveloping the ductwork with a layer of insulation, these fabrics facilitate the reduction of heat transfer and the prevention of energy loss. Furthermore, fiberglass fabrics boast a seamless installation process and the ability to be tailored precisely to meet the unique demands of the ductwork. Moreover, their durability and resistance to moisture render them appropriate for application in both residential and commercial HVAC systems.

- Q: What are the different coatings available for fiberglass fabric?

- There are several different coatings available for fiberglass fabric, each designed to enhance the fabric's performance and provide specific properties. Some of the most common coatings used for fiberglass fabric include: 1. Silicone: Silicone coatings offer excellent heat resistance and are commonly used in applications where high temperatures are involved, such as insulation blankets, removable insulation covers, and fire protection systems. 2. Acrylic: Acrylic coatings provide good weather resistance and durability, making them suitable for outdoor applications. They also offer some level of abrasion resistance and can be used for protective covers, awnings, and banners. 3. Polyurethane: Polyurethane coatings offer high flexibility and elasticity, making them ideal for applications that require fabric to stretch or bend. They provide good resistance to chemicals and UV radiation, making them suitable for use in protective clothing, boat covers, and inflatable structures. 4. PTFE (Polytetrafluoroethylene): PTFE coatings are known for their excellent non-stick properties and resistance to high temperatures. They are commonly used in applications where low friction and high temperature resistance are required, such as conveyor belts, release sheets, and insulation covers. 5. Vinyl: Vinyl coatings offer good water resistance and durability, making them suitable for applications that require fabric to be waterproof. They are commonly used in tarps, truck covers, and outdoor furniture covers. 6. Neoprene: Neoprene coatings provide excellent resistance to oils, chemicals, and abrasion. They are commonly used in applications that require fabric to be resistant to harsh environments, such as protective clothing, gloves, and industrial curtains. It is important to note that each coating has its own set of advantages and limitations, so the choice of coating should be based on the specific requirements of the application.

- Q: Do fiberglass fabrics have any electrical conductivity properties?

- No, fiberglass fabrics do not have any electrical conductivity properties. Fiberglass is an insulator and does not conduct electricity. This property makes it suitable for various applications where electrical insulation is required, such as electrical insulation sleeves, circuit boards, and protective covers for electrical equipment. Additionally, fiberglass fabrics are often used in industries where insulation from heat and fire is necessary, further highlighting their non-conductivity to electricity.

- Q: How does fiberglass fabric compare to other fabric materials in terms of cost?

- Fiberglass fabric tends to be more expensive compared to other fabric materials.

- Q: Can fiberglass fabric be used for making aircraft parts?

- Aircraft parts can indeed be made using fiberglass fabric. Fiberglass, being a material that is both strong and lightweight with excellent mechanical properties, is well-suited for various uses in the aerospace field. Its usage in constructing aircraft parts such as fuselages, wings, fairings, and interior components is quite common. To manufacture fiberglass fabric, thin strands of glass fibers are woven together, resulting in a material that is flexible and adaptable. It possesses a high strength-to-weight ratio, resistance to corrosion, and exceptional thermal insulation properties. These particular characteristics make fiberglass fabric an excellent choice for aircraft production, as it aids in reducing the overall weight of the aircraft while maintaining structural integrity. Moreover, fiberglass fabric is easily moldable into intricate shapes, enabling the production of aerodynamically efficient aircraft components. It can also be impregnated with resins to create a composite material, which further enhances its strength and durability. However, it is crucial to note that fiberglass alone may not suffice for all aircraft parts. In certain instances, it may be used in conjunction with other materials or employed as a reinforcement layer in composite structures. The selection of materials for aircraft parts must take into account the specific requirements and regulations of the aviation industry. Nonetheless, fiberglass fabric remains a viable option for certain applications.

- Q: Can fiberglass fabric be used for insulation in steam systems?

- Yes, fiberglass fabric can be used for insulation in steam systems. Fiberglass fabric is a popular choice for insulation in steam systems due to its excellent thermal insulation properties and resistance to high temperatures. It can effectively trap the heat produced by steam, preventing heat loss and improving energy efficiency in the system. Additionally, fiberglass fabric is lightweight, flexible, and easy to install, making it a convenient option for insulating steam pipes and equipment. Its non-combustible nature also ensures safety in steam systems. Overall, fiberglass fabric is a reliable and effective insulation material for steam systems.

- Q: What are the advantages of using fiberglass fabrics?

- Using fiberglass fabrics in various industries offers several advantages. Firstly, fiberglass fabrics are renowned for their exceptional strength-to-weight ratio. This implies that they possess remarkable strength and durability while maintaining a lightweight composition. Consequently, fiberglass fabrics prove to be ideal for industries that prioritize both strength and weight, such as aerospace and automotive sectors. Secondly, fiberglass fabrics exhibit superb thermal insulation properties. They display remarkable resistance to heat and can endure high temperatures without sacrificing their structural integrity. As a result, they are suitable for applications necessitating heat resistance, including insulation materials and the construction of fire-resistant structures. Another advantage of fiberglass fabrics lies in their resistance to chemicals and corrosion. They demonstrate high resistance to various chemicals, acids, and alkalis, rendering them perfect for environments where exposure to corrosive substances is commonplace, like chemical processing plants or marine applications. Moreover, fiberglass fabrics offer high flexibility and can be effortlessly molded into diverse shapes and forms. This versatility allows for a wide range of applications, ranging from reinforcement materials in composites to the creation of intricate structures in architectural design. Furthermore, fiberglass fabrics are non-conductive and boast excellent electrical insulation properties. Consequently, they are well-suited for electrical applications that require insulation to prevent electric shocks or short circuits. Lastly, fiberglass fabrics are relatively cost-effective compared to other high-performance materials like carbon fiber. They deliver similar properties at a more affordable price, making them a popular choice in industries that prioritize cost-effectiveness. In conclusion, the benefits of utilizing fiberglass fabrics include their impressive strength-to-weight ratio, thermal insulation properties, resistance to chemicals and corrosion, flexibility, electrical insulation properties, and cost-effectiveness. These attributes make fiberglass fabrics a versatile and dependable material for a wide range of applications in various industries.

- Q: Can fiberglass fabric be used for reinforcement in automotive parts?

- Indeed, automotive parts can be reinforced with fiberglass fabric. Renowned for its exceptional strength-to-weight ratio, fiberglass fabric proves to be an optimal material for reinforcing diverse components within automobiles. Its utilization is prevalent in the production of body panels, hoods, fenders, and other integral structural parts of vehicles. By endowing remarkable rigidity and stiffness, fiberglass fabric significantly enhances the overall strength and longevity of automotive parts. Furthermore, its resistance to corrosion, coupled with its ability to endure high temperatures, renders fiberglass fabric highly suitable for deployment within the automotive industry.

- Q: How does fiberglass fabric perform in creep resistance?

- Fiberglass fabric has excellent creep resistance properties. It is able to withstand sustained loads over a long period of time without significant deformation or permanent damage. This makes it an ideal material for applications that require stability and durability under continuous stress.

Send your message to us

vermiculite coated fiberglass cloth high quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords