Heat Resistant PTFE Coated Fiberglass Fabric

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description: PTFE coated fiberglass fabric is fiberglass cloth coated with Polytetrafluoroethylene on the surface to meet customer demands. It offers excellent features such as anti-static, fireproof, heat resistance, corrosion resistance, chemical resistance, waterproof, non-adhesiveness, low coefficient of friction, high tensile strength. PTFE coated fiberglass fabric is compliant for use in high temperature insulation, removable covers and blankets, pipe insulation, food processing, packaging, and handling.Features: fireproof, heat resistance, corrosion resistance, waterproof, anti-static

Application: thermal insulation jacket, high temperature insulation, removable covers and blankets, pipe insulation

PRICE: USD6 per square meter

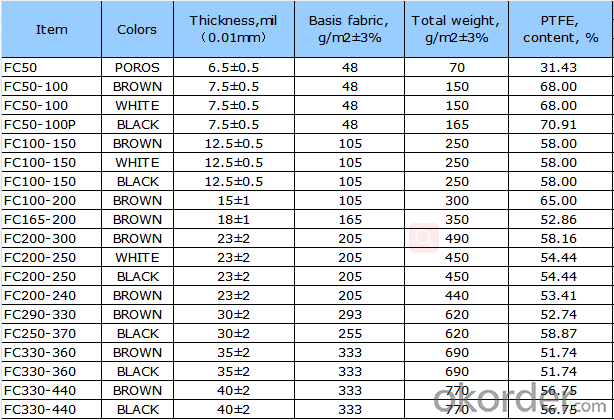

Weight: 400gsm-800gsm

Width: 1m, 1.2m 1.5m or customized

Yarn Type: E-glass

Standing temperature -70℃-260℃

Product name: PTFE coated fiberglass fabric

Coating/Finish/Surface Treatment: PTFE coated

Roll length: 50 meter or customized

Color: brown, black, white, grey, blue, or customized

Weave Type: plain woven

Alkali content: alkali free

Processing service: cutting

Material: fiberglass PTFE

Thickness: 0.3mm to 0.8mm

Size: can be customized

Supply ability: 300000 meters per month

Packaging: PTFE coated fiberglass fabric rolls packed in cartons loaded on pallets or according to customers’ requirements

Lead time: 7-30 days

- Q: Can fiberglass fabric be used for heat-resistant sleeves?

- Indeed, heat-resistant sleeves can be made using fiberglass fabric. The properties of fiberglass fabric make it an excellent choice for heat-resistant applications. It can withstand high temperatures without melting or deforming, thanks to its outstanding heat-resistant capabilities. With a high melting point and resistance to fire, fiberglass fabric is the ideal material to protect against heat. Industries that require heat protection, such as welding, metalworking, and firefighting, often favor fiberglass fabric for its ability to insulate and create a barrier between the user and hot surfaces. Moreover, fiberglass fabric offers additional benefits, including being lightweight, durable, and flexible. These qualities ensure ease of movement and comfort while providing effective heat protection.

- Q: Is fiberglass fabric resistant to fading?

- Yes, fiberglass fabric is highly resistant to fading. Its composition and manufacturing process make it durable and less prone to color fading caused by sunlight exposure or regular use.

- Q: Is fiberglass fabric resistant to termites?

- No, fiberglass fabric is not resistant to termites. Termites are known to feed on organic materials such as wood, paper, and fabric, and fiberglass fabric is not exempt from their feeding habits. While fiberglass fabric may not provide a suitable food source for termites, they can still cause damage to the fabric by chewing through it or using it as a pathway to reach other materials. Therefore, it is important to take appropriate measures to protect fiberglass fabric from termite infestation, such as using termite barriers, regular inspections, and treating the surrounding area for termites if necessary.

- Q: Which is more durable, stone cotton or glass cloth?

- No data connection, I design a variety of heating process, with some experience. You say, 160 degrees brittleness is generally a temperature measurement point and the heat source has a certain distance to show an illusion. The surface of the heat source may have reached a high temperature, and the heating medium is very low. If it is 160 degrees hot air heating, never crack. Welcome to the heating problem.

- Q: Do fiberglass fabrics require any special care or maintenance?

- Special care and maintenance are necessary for the longevity and performance of fiberglass fabrics. Consider the following important points: 1. Cleaning: It is important to clean the fabric regularly to remove dirt, dust, and debris that may accumulate on its surface. Gently scrub the fabric using a soft brush or cloth, avoiding harsh chemicals or abrasive cleaners that could harm it. 2. Storage: Proper storage is crucial when the fabric is not in use to prevent damage. Store it in a clean and dry place, away from direct sunlight or extreme temperatures. Rolling the fabric instead of folding it can help prevent creasing or wrinkling. 3. Avoiding sharp objects: Although fiberglass fabrics are generally durable, they can be punctured or torn by sharp objects. Handle the fabric with care and keep sharp objects away from it to avoid accidental damage. 4. UV protection: Despite being inherently resistant to UV rays, prolonged exposure to direct sunlight can cause fading or degradation over time. To protect the fabric, consider using UV protective sprays or coatings, or providing shading when used outdoors. 5. Repairing: Promptly address any damage to prevent further deterioration. Small holes or tears can be repaired using specialized fiberglass patch kits or adhesive tapes. For larger damages, seek professional repair services. By following these guidelines, fiberglass fabrics can maintain their appearance and functionality for an extended period, ensuring their continued effectiveness in serving their intended purpose.

- Q: How does fiberglass fabric perform in impact resistance?

- Fiberglass fabric performs exceptionally well in impact resistance. Its high strength-to-weight ratio and inherent flexibility make it highly resistant to impact forces. It can withstand heavy impacts without cracking or breaking, making it an ideal choice for applications where impact resistance is crucial, such as in protective equipment, automotive parts, and aerospace components.

- Q: Are there any health risks associated with exposure to fiberglass fabrics?

- Yes, there are potential health risks associated with exposure to fiberglass fabrics. Fiberglass is made of tiny fibers that can become airborne when disturbed, and if inhaled, these fibers can irritate the respiratory system, causing lung irritation, coughing, and shortness of breath. Prolonged exposure to fiberglass can also lead to more serious health issues such as lung scarring and fibrosis. It is important to take proper safety precautions, such as wearing protective clothing and masks, when working with or around fiberglass fabrics to minimize the risk of health problems.

- Q: What is the difference between glass fiber plain cloth and glass fiber grid cloth? What are the specifications and specifications of plain cloth and square cloth?

- Plaid is especially woven fabric woven from roving. The warp and weft are interlaced with 90 angles. Roving refers to a fiber (monofilament with a diameter of 9 microns or more). At present, the industry is generally used, mostly mining 17 microns.

- Q: Can fiberglass fabrics be used for insulation purposes?

- Yes, fiberglass fabrics can be used for insulation purposes. Fiberglass fabrics are made from extremely fine glass fibers that are woven together to form a flexible and lightweight material. This fabric has excellent insulation properties due to its ability to trap air and prevent the transfer of heat or cold. Fiberglass fabrics are commonly used in various insulation applications, including the insulation of pipes, ducts, walls, and roofs. They are also used in the manufacturing of thermal blankets and curtains for insulation purposes. Additionally, fiberglass fabrics can be used in combination with other insulating materials to enhance their overall effectiveness. One of the key advantages of using fiberglass fabrics for insulation is their high thermal resistance. They have a low thermal conductivity, which means that they can significantly reduce heat transfer and maintain stable temperatures in the insulated areas. Fiberglass fabrics are also non-combustible and have good resistance to moisture and chemicals, making them suitable for a wide range of insulation applications. Furthermore, fiberglass fabrics are easy to handle and install. They can be easily cut and shaped to fit specific dimensions, and they can be attached to surfaces using mechanical fasteners or adhesive. This flexibility and ease of installation make fiberglass fabrics a popular choice for both residential and commercial insulation projects. In summary, fiberglass fabrics are an excellent choice for insulation purposes. Their high thermal resistance, durability, and ease of installation make them a versatile and effective solution for various insulation applications.

- Q: Can fiberglass fabric be used for reinforcement in boat decks?

- Indeed, boat decks can benefit from the use of fiberglass fabric for reinforcement. Renowned for its robustness, longevity, and ability to withstand corrosion, fiberglass fabric proves itself as an ideal material for constructing boats. By incorporating fiberglass fabric, boat decks gain structural integrity, reinforcing their overall strength. Moreover, the lightweight nature of fiberglass fabric offers advantages such as improved buoyancy and enhanced fuel efficiency. Furthermore, its exceptional resistance to water and various weather conditions renders it perfectly suitable for marine environments. In summary, fiberglass fabric remains a favored option for reinforcing boat decks due to its strength, durability, resistance to corrosion, and lightweight attributes.

Send your message to us

Heat Resistant PTFE Coated Fiberglass Fabric

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords