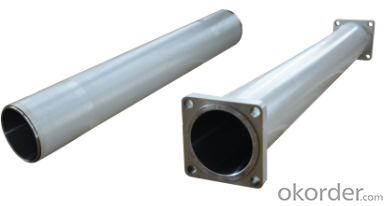

PUMPING CYLINDER(SANY ) I.D.:DN195 CR. THICKNESS :0.25MM-0.3MM LENGTH:1570MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

This Pumping Delivery Cylinder DN195*1570 usually made by steel material we call it No. C45. in China according to customer’s requests, the thickness of chrome is keeped in our factory and also package in bundles or nude packing directly put into container.

Scope of Application of the Cylinders

The Pump Delivery Cylinder DN195*1570 is a concrete pump parts using at hydraulic system, combined use with other concrete pumps parts in concrete pumping operations. It can be widely used in the concrete pumps truck and concrete pump as well.

This Cylinder DN195*1570 can only be used in concrete pump construction operations, but not in any other operations.

Specifications:

Concrete Pump Delivery Cylinder DN195*1570

1. Life: 70,000~90,000cbm

2. Size: DN195

4. Brand: Sany

5. Material: Steel C45

6. Quenching and tempering to improve the hardness to HB241-280

7. Inner wall chrome thickness is 0.25-0.30mm, hardness HV820-900.

Product Advantages:

OKorder's Cylinders DN195*1570 Channels are durable, strong, and safety.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (10-20 days)

Reliable performance

Easy to weld

High safety.

· Professional Service

· Competitive pricing

Measuring of wall thickness from the outside

Low purchase cost

FAQ:

Q1: How long about delivery time?

A1: Normally we keep the raw materials for old customers and sometime we also keep stock products to make sure delivery time in any emergency cases.

Q2: How do we guarantee the quality of our Cylinders DN195*1570?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will book the vessel for goods. The specific shipping date is dependent upon international and government factors, but is typically10 to 30 workdays.

Q4: If we can produce some Cylinders DN195*1570 according to customers request?

A4: Yes, we can produce Cylinders DN195*1570 according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, If needed,

- Q: What is the name of the pump for concrete transportation?

- The concrete name of concrete pump is concrete pump truck. Concrete pump truck is a kind of machine which can transport concrete along pipeline continuously by pressure. It is composed of pump body and conveying pipe.

- Q: How to operate the concrete pump?

- All the bolts of the pumping unit shall be fastened, and the pipe joints shall be tightly sealed. The protective devices shall be complete and reliable

- Q: Are there any specific cleaning and maintenance procedures for concrete pump spare parts?

- Yes, there are specific cleaning and maintenance procedures for concrete pump spare parts. Regular cleaning of the spare parts is necessary to remove any dirt, debris, or concrete buildup that may affect their performance. This can be done using water, mild detergent, and a brush to scrub the parts gently. Additionally, lubrication of moving parts and regular inspection for wear and tear is crucial to ensure optimal functioning and longevity of the spare parts.

- Q: What are the different types of concrete pump hopper agitator blades?

- In the construction industry, there exists a variety of concrete pump hopper agitator blades. These blades have different designs and functions, all aimed at efficiently mixing and agitating the concrete mixture in the hopper. By achieving a consistent and homogeneous mixture, the concrete can be pumped onto the project site effectively. 1. Paddle Blades: The most commonly used agitator blades in concrete pump hoppers are paddle blades. These blades have a flat, paddle-like design that effectively mixes the concrete ingredients. They are typically made of high-quality steel or hardened rubber to ensure durability and optimal performance. 2. Helical Blades: Another type of agitator blade is the helical blade, which has a spiral shape. This design creates a gentle, swirling motion within the hopper, preventing the formation of lumps and ensuring a smooth and well-mixed concrete mixture. 3. Ribbon Blades: Thin and flat, ribbon blades resemble ribbons and are placed vertically in the hopper. They rotate along their axis to thoroughly mix the concrete ingredients. Ribbon blades are known for their ability to prevent clogging and improve the efficiency of concrete pumping. 4. Fan Blades: With a unique fan-shaped design, fan blades create a powerful airflow within the hopper to agitate the concrete mixture. This type of blade is particularly effective in preventing the segregation of concrete ingredients and maintaining a consistent mixture. 5. Tine Blades: Tine blades feature multiple prongs or tines extending from a central hub. They provide a more aggressive agitation action, making them suitable for mixing heavier concrete mixes or those containing large aggregates. The selection of agitator blades depends on various factors, such as the type of concrete, desired consistency, and specific project requirements. It is crucial to choose the appropriate blade type and perform regular maintenance to optimize the performance and lifespan of the concrete pump hopper agitator.

- Q: Are there any specific maintenance practices for concrete pump spare parts?

- Concrete pump spare parts should be regularly inspected for signs of wear or damage. This involves checking for visible defects like cracks, leaks, or any other issues. If any problems are found, the spare parts should be immediately replaced or repaired to prevent further damage. Regular cleaning is also essential for concrete pump spare parts. These parts often come into contact with cement, water, and other substances that can cause build-up and affect their performance. Cleaning them regularly will remove debris and residue, ensuring optimal functionality. Lubrication is another important maintenance practice for concrete pump spare parts. Properly lubricating moving components like bearings, seals, and pistons reduces friction and wear, extending the lifespan of the parts. It's crucial to use the correct lubricants recommended by the manufacturer and follow their application guidelines. Proper storage is also vital for maintaining spare parts. They should be stored in a clean, dry environment, away from chemicals or substances that could damage them. Additionally, spare parts should be protected from physical damage, such as being dropped or bumped. Lastly, it's recommended to adhere to the manufacturer's maintenance and replacement guidelines. Regular servicing and inspections by qualified technicians can help identify potential issues early on and prevent major breakdowns or failures. In summary, following specific maintenance practices like regular inspection, cleaning, lubrication, proper storage, and adherence to manufacturer's guidelines are crucial for ensuring optimal performance and longevity of concrete pump spare parts.

- Q: How often should concrete pump remote control antennas be inspected and replaced?

- To ensure optimal functionality, it is necessary to regularly inspect the antennas of the concrete pump remote control. The frequency of these inspections will vary depending on the usage and working conditions of the pump. In general, it is advisable to conduct inspections at least once a year or after every 500 hours of usage, whichever occurs first. However, if the pump is subjected to harsh environments or experiences frequent wear and tear, more frequent inspections may be required. It is crucial to carefully examine the antennas for any indications of damage, such as cracks, corrosion, or loose connections. If any damage is detected, immediate replacement of the antenna is essential to prevent disruptions in the remote control signal. By conducting regular inspections and promptly replacing antennas when necessary, the concrete pump can operate smoothly and efficiently.

- Q: What are the different types of concrete pump control system sensors?

- Concrete pump control systems utilize a variety of sensors to ensure smooth and efficient operation. These sensors are specifically designed to monitor different aspects of the pump's performance and provide real-time feedback to the control system. Common types of sensors used in concrete pump control systems include: 1. Pressure Sensors: These sensors measure the concrete pressure during pumping. They are typically installed in the discharge line and are crucial in preventing over-pressurization and potential damage to the pump or pipeline. 2. Flow Sensors: Flow sensors measure the rate at which concrete flows through the system. By monitoring the volume of concrete passing through per unit of time, these sensors enable the control system to regulate the pump's speed and output accordingly. 3. Level Sensors: Level sensors monitor the concrete level in the hopper or storage tank. They provide information about the concrete volume to prevent the pump from running dry or becoming overloaded, thus preventing pump cavitation or blockages. 4. Proximity Sensors: Proximity sensors detect the position of moving parts in the pump system, such as the boom or outriggers. They ensure safe operation by providing feedback to the control system and preventing collisions or obstructions. 5. Temperature Sensors: Temperature sensors monitor the concrete mix temperature. They help maintain the desired temperature range during pumping, which is crucial for workability and curing. Optimal concrete temperature contributes to the quality of the final product. In summary, these sensors work in harmony to provide precise feedback to the control system, ensuring efficient and safe operation of the concrete pump. By continuously monitoring and adjusting various parameters, these sensors optimize pumping performance and enhance productivity in concrete placement projects.

- Q: How can a damaged concrete pump piston affect the pumping efficiency?

- The pumping efficiency can be significantly affected in various ways by a piston that is damaged. To begin with, reduced pumping capacity can result from decreased power and force exerted by the pump due to a damaged piston. The piston's responsibility is to generate the necessary pressure for pushing the concrete mixture through the pumping system. If it is damaged, it may fail to generate adequate pressure, leading to slower and less efficient pumping. In addition, leaks can occur within the pump system due to a damaged piston. The piston plays a critical role in sealing the concrete and preventing it from leaking back into the hopper. If it is damaged or worn out, a tight seal may not be created, resulting in leakage. This not only leads to material loss but also reduces pumping efficiency as the pump has to compensate for the loss by working harder. Moreover, blockages and clogs can be caused by a damaged piston in the pumping system. The movement of the piston creates suction, which pulls the concrete mixture into the pump. If the piston is damaged, it may not create sufficient suction, causing the mixture to flow unevenly or get stuck in the system. This can cause delays and interruptions in the pumping process, ultimately reducing overall efficiency. In conclusion, the pumping efficiency can be negatively impacted by a damaged concrete pump piston through reduced power and force, leaks, and blockages. It is crucial to regularly maintain and promptly repair or replace damaged pistons to ensure optimal pumping performance and efficiency.

- Q: How can a malfunctioning control lever affect the pump's operation?

- A malfunctioning control lever can significantly impact the pump's operation in several ways. Firstly, the control lever is responsible for regulating the flow rate and pressure of the pump. If the lever is malfunctioning, it may not be able to accurately adjust these parameters, leading to improper functioning of the pump. Secondly, a malfunctioning control lever may not be able to switch the pump on or off effectively. This can result in the pump continuously running, even when it is not required, leading to unnecessary wear and tear on the pump and increased energy consumption. Additionally, the control lever is often used to control the direction of flow in the pump. If it is malfunctioning, it may not be able to switch the pump between forward and reverse modes, affecting the pump's ability to perform its intended tasks efficiently. Furthermore, a malfunctioning control lever can impact the overall safety of the pump operation. If the lever fails to respond or gets stuck in a position, it can potentially lead to over-pressurization, leaks, or other hazardous situations, putting both the pump and surrounding equipment or personnel at risk. In summary, a malfunctioning control lever can disrupt the pump's ability to accurately regulate flow rate, pressure, and direction of flow, potentially leading to improper functioning, increased energy consumption, reduced efficiency, and safety hazards. Therefore, it is crucial to promptly address any issues with the control lever to ensure the reliable operation of the pump.

- Q: What are the common signs of wear and tear in a concrete pump cylinder?

- Some common signs of wear and tear in a concrete pump cylinder include: 1. Leaking oil or hydraulic fluid: If you notice oil or hydraulic fluid leaking from the cylinder, it is a clear sign of damage or wear. This can be caused by cracks, worn seals, or damaged gaskets. 2. Reduced pumping efficiency: A worn cylinder may result in decreased pumping efficiency, meaning the concrete pump may not be able to deliver the same amount of concrete as before. This can be due to a decrease in the cylinder's internal diameter or worn piston rings. 3. Increased noise and vibration: As the cylinder wears down, it may create more noise and vibration during operation. This can indicate misalignment, loose components, or damaged internal parts. 4. Rough or uneven concrete output: A worn cylinder can lead to a rough or uneven output of concrete. This can be caused by an irregular internal surface or damaged piston rings, affecting the smooth movement of the piston. 5. Excessive heat generation: If the concrete pump cylinder is worn, it may generate more heat during operation. This can be caused by increased friction between moving parts, which can further contribute to accelerated wear and tear. 6. Visible damage or corrosion: Inspecting the surface of the cylinder can reveal visible signs of wear and tear, such as scratches, dents, or corrosion. These damages can compromise the integrity of the cylinder and may require repair or replacement. It is important to regularly inspect the concrete pump cylinder and address any signs of wear and tear promptly to avoid further damage and ensure the pump's optimal performance.

Send your message to us

PUMPING CYLINDER(SANY ) I.D.:DN195 CR. THICKNESS :0.25MM-0.3MM LENGTH:1570MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords