PUMPING CYLINDER(SANY ) I.D.:DN180 CR. THICKNESS :0.25MM-0.3MM LENGTH:1545MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

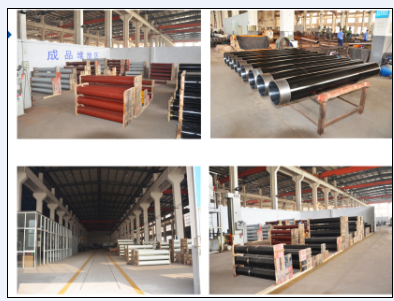

The Concrete Pump Delivery Cylinder DN180*1545 normally made by steel material No. C45. according to customer’s requests, and also package in bundles or nude packing directly put into container.

Scope of Application of the Cylinders

The Pump Delivery Cylinder DN180*1545 is a Cylinder pumping for combined use with other concrete pumps parts in concrete pumping operations. It can be widely used in the construction of various types of concrete structures like industrial and civil buildings, bridges, roads, and other types of infrastructure.

This Cylinder Cylinder DN180*1545 can only be used in concrete pump construction operations, but not in any other operations, like dragging, moving, or hoisting heavy articles or personnel. The pipe is also not allowed to be used in any location where any combustible or explosive material exists or a cave-in may occur.

Specifications:

Concrete Pump Delivery Cylinder DN180*1545

1. Capacity: 60,000~80,000cbm

2. Size: DN180, DN200, DN230.DN250

3. Material: C45

4. quenching and tempering to improve the hardness to HB241-280

5. inner wall chrome thickness is 0.25-0.30mm, hardness HV820-900.

6. Brand: SCHWING, PM, SANY, KYOKUTO, CIFA

7. Capacity: 60,000~80,000cbm

Product Advantages:

OKorder's Cylinders DN180*1545 Channels are durable, strong, and safety.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (10-20 days)

Reliable performance

Easy to weld

High safety.

· Professional Service

· Competitive pricing

Measuring of wall thickness from the outside

Low purchase cost

FAQ:

Q1: How long about delivery time about DN180*1545 ?

A1: Normally we keep the raw materials for old customers and sometime we also keep stock products to make sure delivery time in any emergency cases.

Q2: How do we guarantee the quality of our Cylinders DN180*1545?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will book the vessel for goods. The specific shipping date is dependent upon international and government factors, but is typically10 to 30 workdays.

Q4: If we can produce some Cylinders DN180*1545 according to customers request?

A4: Yes, we can produce Cylinders DN180*1545 according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, If needed,

- Q: How often should hopper screens be cleaned or replaced?

- It is important to clean or replace hopper screens regularly, usually every 3 to 6 months, depending on how often they are used and the type of materials being processed. Keeping the hopper screens clean is crucial for maintaining peak performance and preventing clogs or obstructions. If the screens become excessively dirty or damaged, they should be replaced immediately to avoid interruptions in material flow and potential equipment damage. Regularly maintaining and inspecting the hopper screens will help extend their lifespan and ensure the entire system operates smoothly.

- Q: How does a hopper agitator motor ensure consistent concrete mixing?

- A hopper agitator motor ensures consistent concrete mixing by providing a continuous and powerful agitation motion within the hopper. This motion helps to break up any clumps or aggregates in the concrete mix, ensuring that all components are evenly distributed. The consistent agitation also helps to prevent settling or segregation of the mixture, resulting in a uniform and well-mixed concrete batch.

- Q: Are there any specific guidelines for the installation of hopper components or agitators in concrete pump spare parts?

- Yes, there are specific guidelines for the installation of hopper components or agitators in concrete pump spare parts. These guidelines typically include instructions on proper alignment, securing of bolts, lubrication, and ensuring all components are properly connected. It is important to follow these guidelines to ensure safe and efficient operation of the concrete pump.

- Q: How often should concrete pump pressure gauges be inspected and replaced?

- Concrete pump pressure gauges should be inspected regularly to ensure their accuracy and functionality. The frequency of inspection and replacement may vary depending on the specific conditions and usage of the concrete pump. However, as a general guideline, it is recommended to inspect and replace pressure gauges at least once a year or after every 500 pumping hours, whichever comes first. This regular inspection and replacement schedule helps to avoid any potential inaccuracies or malfunctions that could compromise the safety and efficiency of the concrete pumping operations. Additionally, it is important to follow the manufacturer's recommendations and guidelines for pressure gauge maintenance and replacement to ensure optimal performance and longevity.

- Q: How does a hopper vibrator prevent concrete blockages?

- A hopper vibrator serves as a mechanical solution to avoid concrete blockages in construction equipment like concrete pumps and mixers. Its purpose is to apply vibrations to the hopper, which is the large container where the concrete is stored prior to pouring or transferring. Concrete blockages commonly occur due to the tendency of the material to settle and compact, particularly during prolonged storage or transportation. This can result in the clogging and obstruction of concrete flow, thereby impeding the construction process and potentially causing equipment damage. Through the utilization of a hopper vibrator, the vibrations are transmitted to the concrete within the hopper, effectively preventing settling and compaction. The vibrations loosen the concrete particles, ensuring they remain in a more fluid state. This facilitates a continuous and smooth flow of concrete, preventing any blockages or obstructions from arising. Furthermore, the vibrations from the hopper vibrator also aid in dislodging any existing blockages. The shaking motion can break apart concrete clumps or other debris obstructing the flow, enabling uninterrupted material movement. Overall, a hopper vibrator is an indispensable tool in construction equipment as it helps maintain a consistent concrete flow, thereby preventing blockages and ensuring the smooth and efficient operation of the construction process.

- Q: Are there any specific regulations or standards for the labeling and packaging of concrete pump spare parts?

- Concrete pump spare parts are subject to specific regulations and standards regarding their labeling and packaging. These regulations and standards aim to guarantee safety, proper handling, and ease of identification for these spare parts. A key regulation requires clear and legible labeling on the packaging of concrete pump spare parts. This labeling must include essential information such as the manufacturer's name, part number, description, as well as any specific instructions or warnings for handling and installation. This ensures that users can easily identify the spare parts and comprehend their purpose and correct usage. Furthermore, specific standards may exist for the packaging material utilized for concrete pump spare parts. These standards may demand the use of durable and protective packaging materials to prevent damage during transportation and storage. By doing so, the quality and functionality of the spare parts are preserved until they are ready for use. Moreover, regulations may be in place regarding the labeling and packaging of spare parts concerning safety. For instance, certain spare parts may necessitate special labeling or packaging to indicate the presence of hazardous materials or potential risks if mishandled. This is crucial for ensuring the safety of those handling the spare parts and for compliance with relevant safety regulations. In conclusion, the labeling and packaging of concrete pump spare parts are governed by specific regulations and standards to ensure proper identification, handling, and safety. These regulations and standards play a vital role in upholding a high level of quality and reliability for these spare parts within the construction industry.

- Q: How often should hopper grate springs be inspected or replaced in a concrete pump?

- To ensure optimal performance and prevent potential issues, it is essential to regularly inspect the hopper grate springs in a concrete pump. The frequency of inspection or replacement depends on factors such as pump usage, operating conditions, and manufacturer recommendations. However, a general rule is to inspect the springs at least every six months or after every 500 hours of operation, whichever comes first. During the inspection, thoroughly examine the springs for any signs of wear, damage, or deformation. Check for cracks, excessive rust, or loss of tension. If any of these issues are found, immediate replacement is necessary to maintain proper functioning of the hopper grate system. Regular inspection and timely replacement of hopper grate springs are vital to prevent clogging or blockage in the hopper, which can lead to pump malfunctions or downtime. It is advisable to consult the concrete pump manufacturer's guidelines or seek assistance from a professional technician to determine specific inspection and replacement intervals based on the pump's make and model.

- Q: How often should concrete pump hydraulic motors be inspected and replaced?

- The frequency at which concrete pump hydraulic motors should be inspected and replaced depends on various factors such as the usage intensity, maintenance practices, and the specific manufacturer's guidelines. However, as a general rule of thumb, it is recommended to inspect hydraulic motors at least once every 6 to 12 months. This inspection should involve checking for any signs of wear and tear, leaks, or abnormal noises during operation. Regular maintenance, such as lubrication and cleaning, should also be performed as per the manufacturer's recommendations. Ultimately, the decision to replace hydraulic motors should be based on their condition and performance. If there are noticeable issues or a significant decrease in efficiency, it may be necessary to replace the hydraulic motors sooner than the suggested inspection interval.

- Q: How often should hopper pins be inspected or replaced in a concrete pump?

- Hopper pins in a concrete pump should be inspected regularly, preferably before each use, to ensure they are in proper working condition. The frequency of replacement will depend on various factors such as the quality of the pins, the intensity of use, and the maintenance practices employed. However, it is recommended to replace hopper pins as soon as any signs of wear, damage, or weakening are detected to prevent potential accidents or malfunctions.

- Q: Are there any specific safety precautions while replacing concrete pump spare parts?

- There exists a variety of safety precautions that must be followed when replacing concrete pump spare parts. 1. Personal Protective Equipment (PPE) is of utmost importance and should be worn to safeguard against potential hazards. This includes safety goggles, gloves, a helmet, and steel-toed boots. 2. It is essential to adhere to proper lockout/tagout procedures prior to replacing any spare parts. This entails disconnecting and securing the power source to prevent accidental startup of the pump. 3. Before commencing the replacement process, inspect all tools and equipment for any indications of damage or defects. It is crucial to refrain from using faulty equipment, as it can pose significant safety risks. 4. When handling heavy spare parts, it is imperative to employ appropriate lifting techniques to prevent strain or injury. Ensure that proper assistance and equipment, such as cranes or forklifts, are available if necessary. 5. Maintain a clean and well-organized work area to prevent trips, slips, and falls. Remove any obstacles or debris that may jeopardize safety during the replacement process. 6. Only trained and authorized personnel should be involved in the replacement of concrete pump spare parts. They must possess a thorough understanding of the equipment and procedures to minimize the likelihood of accidents. 7. Always consult the manufacturer's guidelines and instructions when replacing spare parts. This will ensure that the process is executed safely and accurately. 8. It is vital to have a plan in place for potential emergencies, including fires or injuries. Make certain that fire extinguishers and first aid kits are easily accessible, and that all workers are familiar with their locations and usage. By adhering to these safety precautions, the risk of accidents, injuries, and damage can be significantly reduced when replacing concrete pump spare parts.

Send your message to us

PUMPING CYLINDER(SANY ) I.D.:DN180 CR. THICKNESS :0.25MM-0.3MM LENGTH:1545MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords