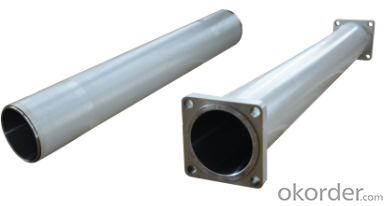

PUMPING CYLINDER(SANY ) I.D.:DN200 CR. THICKNESS :0.25MM-0.3MM LENGTH:1946MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

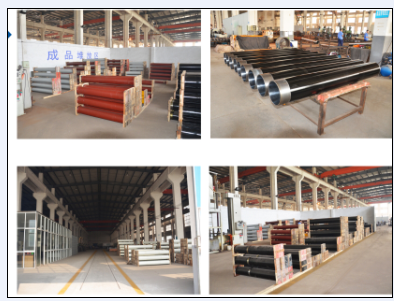

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

The Concrete Pump Delivery Cylinder DN200*1946 normally made by steel material No. C45. according to customer’s requests, and also package in bundles or nude packing directly put into container.

Scope of Application of the Cylinders

The Pump Delivery Cylinder DN200*1946 is a Cylinder pumping for combined use with other concrete pumps parts in concrete pumping operations. It can be widely used in the construction of various types of concrete structures like industrial and civil buildings, bridges, roads, and other types of infrastructure.

This Cylinder Cylinder DN200*1946 can only be used in concrete pump construction operations, but not in any other operations, like dragging, moving, or hoisting heavy articles or personnel. The pipe is also not allowed to be used in any location where any combustible or explosive material exists or a cave-in may occur.

Specifications:

Concrete Pump Delivery Cylinder DN200*1946

1. Capacity: 60,000~80,000cbm

2. Size: DN180, DN200, DN230.DN250

3. Material: C45

4. quenching and tempering to improve the hardness to HB241-280

5. inner wall chrome thickness is 0.25-0.30mm, hardness HV820-900.

6. Brand: SCHWING, PM, SANY, KYOKUTO, CIFA

7. Capacity: 60,000~80,000cbm

Product Advantages:

OKorder's Cylinders DN200*1946 Channels are durable, strong, and safety.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (10-20 days)

Reliable performance

Easy to weld

High safety.

· Professional Service

· Competitive pricing

Measuring of wall thickness from the outside

Low purchase cost

FAQ:

Q1: How long about delivery time about DN200*1946 ?

A1: Normally we keep the raw materials for old customers and sometime we also keep stock products to make sure delivery time in any emergency cases.

Q2: How do we guarantee the quality of our Cylinders DN200*1946?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will book the vessel for goods. The specific shipping date is dependent upon international and government factors, but is typically10 to 30 workdays.

Q4: If we can produce some Cylinders DN200*1946 according to customers request?

A4: Yes, we can produce Cylinders DN200*1946 according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, If needed,

p;

- Q: What are the signs of wear and tear in concrete pump spare parts?

- Some signs of wear and tear in concrete pump spare parts include cracks or fractures in the components, excessive vibration or noise during operation, decreased performance or efficiency, leaks or drips from seals or connectors, and visible corrosion or rust on metal parts. Additionally, worn-out or damaged rubber gaskets, seals, or O-rings can also indicate the need for replacement.

- Q: How can one identify the correct type of rubber seals or gaskets for concrete pump spare parts?

- To identify the correct type of rubber seals or gaskets for concrete pump spare parts, there are a few steps you can follow: 1. Consult the manufacturer's documentation: Check the concrete pump's manual or any accompanying documentation provided by the manufacturer. This information will usually specify the type and size of rubber seals or gaskets required for different parts of the pump. 2. Measure the dimensions: Take precise measurements of the seals or gaskets that need replacement. This includes the inner diameter, outer diameter, and thickness. These measurements will help you find the right size of seals or gaskets. 3. Material compatibility: Consider the material compatibility between the rubber seals or gaskets and the concrete being pumped. Concrete may contain chemicals or additives that can degrade certain types of rubber. Ensure that the seals or gaskets you choose are made of a material that is resistant to the specific chemicals present in the concrete. 4. Seek expert advice: If you are unsure about the specific type of rubber seal or gasket required for your concrete pump, it is always advisable to seek expert advice. Contact the manufacturer directly or consult a reputable supplier or distributor who specializes in concrete pump spare parts. They can provide guidance and recommend the correct type of seals or gaskets based on your specific pump model and requirements. Remember, using the correct type of rubber seals or gaskets is crucial for maintaining the efficiency and safety of your concrete pump. Taking the time to identify the right parts will help ensure optimal performance and minimize the risk of premature wear or failure.

- Q: How can a faulty boom affect the concrete placement process?

- A faulty boom can significantly affect the concrete placement process. It can lead to uneven distribution of concrete, resulting in inconsistent concrete strength and quality. It may also cause the concrete to be placed in unintended areas or at incorrect heights, affecting the overall structural integrity of the project. Additionally, a faulty boom can pose a safety risk to workers and equipment involved in the concrete placement process.

- Q: Can I get spare parts for concrete pump hopper agitators and vibrators?

- Generally, spare parts for concrete pump hopper agitators and vibrators can be easily found. These components are readily available from various manufacturers and suppliers who specialize in construction equipment and machinery. To check for availability and pricing, it is advisable to reach out to the concrete pump manufacturer or their authorized dealer. Another option is to explore online platforms and marketplaces that offer a diverse selection of spare parts for construction equipment, including concrete pump components. To ensure compatibility and optimal performance, it is crucial to provide detailed information about the make and model of the concrete pump when purchasing spare parts.

- Q: How often should concrete pump pistons be replaced?

- The frequency of replacing concrete pump pistons can vary depending on several factors such as the type of pump, the quality of the pistons, and the intensity of usage. However, as a general guideline, concrete pump pistons should be inspected regularly and replaced whenever signs of excessive wear or damage are observed. Timely replacement is crucial to ensure optimal pumping performance and prevent potential breakdowns.

- Q: Can concrete pump spare parts be installed by the pump owner or operator, or is professional assistance required?

- The pump owner or operator has the option to install concrete pump spare parts themselves, but it is strongly advised to seek professional help. The installation of these spare parts necessitates technical expertise and know-how to guarantee correct and effective installation. By opting for professional assistance, one can ensure that the spare parts are accurately installed, reducing the possibility of any damage or malfunction. Moreover, professionals possess the essential tools and equipment to safely and efficiently carry out the installation procedure. By investing in professional assistance, not only is a successful installation guaranteed, but it also contributes to the long-term durability and optimal functioning of the concrete pump.

- Q: How often should hopper agitator shaft bearings be inspected or replaced in a concrete pump?

- The frequency at which hopper agitator shaft bearings in a concrete pump need to be inspected or replaced can vary depending on several factors. These factors include the recommendations from the manufacturer, the operating conditions, and the maintenance history of the pump. However, as a general rule, it is advisable to inspect these bearings at least once a year or every 500-1000 hours of operation, whichever comes first. During regular inspections, it is crucial to check for any indications of wear, damage, or excessive movement in the bearings. If any abnormalities are identified during the inspection, immediate action should be taken to address the problem. In some instances, lubrication or adjustment might be enough to rectify minor issues, whereas more significant damage or wear may necessitate replacing the bearings. It is essential to recognize the vital role that hopper agitator shaft bearings play in ensuring the smooth and efficient functioning of the concrete pump. Neglecting regular inspections or delaying necessary replacements can result in increased downtime, reduced productivity, and potential safety risks. Therefore, it is recommended to adhere to the manufacturer's guidelines and seek advice from experienced technicians or specialists for a more precise evaluation of the specific intervals for inspection and replacement in your concrete pump.

- Q: Are there any warranties or guarantees available for concrete pump spare parts?

- Concrete pump spare parts come with warranties and guarantees to ensure their quality and performance. Various manufacturers and suppliers provide these warranties, which typically cover defects in materials or workmanship. The coverage period usually ranges from a few months to a year or more. Furthermore, some suppliers offer guarantees on the performance or durability of their spare parts, providing customers with reassurance. To ensure your protection in case of any issues, it is advisable to inquire about the specific warranty or guarantee terms before purchasing concrete pump spare parts.

- Q: Are there any online resources or manuals available for concrete pump spare parts?

- Indeed, the online realm offers a plethora of resources and manuals for concrete pump spare parts. Numerous manufacturers and suppliers of such components have established their own websites, which furnish comprehensive details concerning their products, encompassing manuals, catalogs, and technical specifications. It is worth noting that these websites often dedicate sections or pages specifically for spare parts, facilitating the acquisition of information pertaining to diverse types of spare parts, their compatibility with various pump models, and the process of ordering them. In addition to the aforementioned manufacturer websites, there exists a profusion of online marketplaces and directories that specialize in construction equipment and spare parts. These platforms empower users to conduct targeted searches for concrete pump spare parts, enabling the comparison of prices and specifications provided by different suppliers. Furthermore, some of these platforms offer supplementary resources, including user reviews, ratings, and guides to assist in selecting the appropriate spare parts for a given pump model. Moreover, online forums and communities cater to professionals in the construction industry, furnishing platforms for the exchange of information and discussions concerning concrete pumps and their spare parts. These forums serve as invaluable resources for obtaining recommendations, resolving common issues, and connecting with experts capable of offering guidance on sourcing and maintaining spare parts for concrete pumps. Overall, regardless of whether one is a concrete pump operator, maintenance technician, or an individual seeking spare parts for a concrete pump, the online domain abounds with resources that can provide the necessary information and manuals.

- Q: What are the common issues that require replacement of concrete pump spare parts?

- Concrete pumps can experience various issues that necessitate the replacement of spare parts. One prevalent problem is the gradual deterioration of pump components due to wear and tear. Continuous movement of concrete through the pump causes deterioration of parts like the piston, wear plate, and seals, which then need to be replaced. Another issue that may arise is blockages or clogs in the pump line. This occurs when hardened concrete or other debris accumulates, obstructing the flow of concrete. In such cases, replacing parts like the delivery pipe, hose, or even the entire pump line becomes necessary to ensure proper functioning. Leaks are also a common problem in concrete pumps. These leaks often result from damaged or worn-out seals, gaskets, or O-rings. If left unattended, leaks can lead to reduced pump performance and potential safety hazards. Replacing the affected parts helps prevent further damage and ensures efficient pump operation. Additionally, pump malfunctions can be attributed to electrical or mechanical issues. Faulty electrical components, such as switches or sensors, may require replacement to restore proper functionality. Mechanical problems, such as a worn-out gearbox or a malfunctioning hydraulic system, may also necessitate the replacement of specific pump parts. In summary, common issues that call for the replacement of concrete pump spare parts include wear and tear, blockages, leaks, electrical malfunctions, and mechanical failures. Regular maintenance and inspection of the pump enable early identification of these issues, allowing for timely replacement of the necessary spare parts to maintain smooth pump operation.

Send your message to us

PUMPING CYLINDER(SANY ) I.D.:DN200 CR. THICKNESS :0.25MM-0.3MM LENGTH:1946MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords