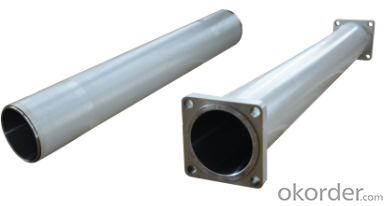

PUMPING CYLINDER(SANY ) I.D.:DN230 CR. THICKNESS :0.25MM-0.3MM LENGTH:2146MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Concrete Pump Delivery Cylinder DN230*2146

1. Capacity: 60,000~80,000cbm

2. Size: DN180, DN200, DN230..

4. Brand: PM, Sany,ZM

Concrete Pump Delivery Cylinder DN230*2146

1. Material: C45

2. quenching and tempering to improve the hardness to HB241-280

3. inner wall chrome thickness is 0.25-0.30mm, hardness HV820-900.

4. Brand: SCHWING, PM, SANY, KYOKUTO, CIFA

5. Capacity: 60,000~80,000cbm

Concrete Cylinder | ||

Material | High Manganese Steel | |

Special | Coating hardness layer in the internalwall | |

Application | In concrete pump trucks | |

For Brand | Sany,Putzmeister,Schwing,,Zoomlion,CIFA etc | |

Details information | ||

Brand | Model | |

219 - DN180*1775-1600 | ||

Schwing | BP3000 | 219 - DN200*1775-1600 |

254 - DN230*2125-1800 | ||

DN230*2300mm | ||

DN230*2100mm | ||

Putzmeister | DN230*1600mm | |

DN200*1600mm | ||

DN180*2000mm | ||

40C1410 | 206-DN180*1530-1400 | |

50C1410 | 210- DN180*1545-1400 | |

60A1406 | 219- DN195*1570-1400 | |

Sany | 60C1416 | 226- DN195*1570-1400 |

60C1816 | 232- DN200*1946-1800 | |

C120/37A | 232- DN200*2162-2000 | |

C120/48 | 262- DN230*2146-2000 | |

62EA | 203-DN 180*1605-1400 | |

62G | 219-DN200*1187-1000 | |

62D | 219-DN200*1587-1400 | |

Zoomlion | 62H | 219-DN200*1787-1600 |

62CA | 219-DN200*1862-1600 | |

62M | 219-DN200*2022-1800 | |

0019931A | 219-DN200*2022-1800 | |

62L | 245-DN205*2284-2000 | |

- Q: How does a concrete pump agitator motor prevent concrete from settling?

- A concrete pump agitator motor prevents concrete from settling by constantly agitating the mixture. The motor is typically equipped with paddles or blades that rotate inside the mixing drum, ensuring that the concrete remains in a homogeneous state. When concrete is being transported, it tends to separate due to gravity and the natural settling of heavier aggregates. This can result in a non-uniform consistency, with denser materials sinking to the bottom and water rising to the top. The agitator motor counteracts this settling process by continuously stirring the concrete. The rotating paddles or blades create a turbulent flow within the mixing drum, preventing the heavier aggregates from settling and maintaining a consistent mixture. This agitation helps to evenly distribute the cement, aggregates, water, and any additional additives throughout the concrete, resulting in a more uniform and reliable end product. By preventing the settling of concrete, the agitator motor ensures that the mixture is consistently workable and can be pumped or poured without any blockages or inconsistencies. This is especially crucial during construction projects where precise and consistent concrete placement is required. In summary, a concrete pump agitator motor prevents settling by agitating the mixture, keeping it homogeneous and ensuring a consistent flow during pumping or pouring operations.

- Q: Are there any safety considerations when using concrete pump spare parts?

- Yes, there are several safety considerations that should be taken into account when using concrete pump spare parts. Firstly, it is important to ensure that the spare parts are of high quality and are compatible with the specific make and model of the concrete pump. Using substandard or incorrect spare parts can lead to equipment failure, which can be dangerous for the operator and those working in the vicinity. Additionally, proper maintenance and inspection of the spare parts is crucial for safety. Regularly inspecting the parts for any signs of wear or damage can help identify potential issues before they cause accidents or equipment failure. It is also important to follow the manufacturer's guidelines for maintenance and replacement intervals. When using concrete pump spare parts, it is essential to follow all safety procedures and protocols. This includes wearing appropriate personal protective equipment (PPE), such as safety goggles, gloves, and steel-toed boots. It is also important to ensure that all operators are trained in the proper use of the equipment and understand the potential hazards involved. Furthermore, it is crucial to follow safe operating practices when using concrete pump spare parts. This includes maintaining a safe distance from the working area, ensuring that the concrete pump is stable and secure, and avoiding overloading or exceeding the recommended operating capacity. By considering these safety considerations and following proper procedures, the risks associated with using concrete pump spare parts can be minimized, ensuring the safety of operators and those working on the construction site.

- Q: How often should a concrete pump cleaning ball be used?

- To guarantee the cleanliness and optimal operation of the pump, it is necessary to employ a concrete pump cleaning ball after each pumping task or at the very least, on a daily basis. This cleaning ball aids in the elimination of any residue or particles that might have amassed within the pump and its conduits during the pumping procedure. Consistently utilizing a cleaning ball prevents the occurrence of obstructions and hindrances, thereby ensuring a seamless and effective pumping operation.

- Q: How does a hopper agitator motor ensure consistent concrete mixing?

- A hopper agitator motor ensures consistent concrete mixing by providing the necessary agitation and movement within the hopper. The motor is designed to rotate and move the agitator blades, which helps in effectively mixing the concrete ingredients. The primary function of the hopper agitator motor is to prevent the concrete from settling or segregating during the mixing process. As the motor rotates, it creates a swirling motion inside the hopper, ensuring that all the ingredients are evenly distributed and thoroughly mixed. This prevents any clumps or inconsistencies in the final concrete mixture. Additionally, the motor also helps in breaking up any lumps or clusters that may have formed within the hopper. This action further enhances the uniformity of the mixture and ensures that all the components, such as cement, aggregates, water, and additives, are properly blended together. Furthermore, the continuous movement of the agitator blades also helps in maintaining the desired consistency and homogeneity of the concrete mix. It prevents the heavier particles from settling at the bottom of the hopper, ensuring that the mixture remains consistent throughout the entire mixing process. Overall, the hopper agitator motor plays a crucial role in ensuring consistent concrete mixing by providing the necessary agitation, preventing segregation, breaking up lumps, and maintaining uniformity. Its rotational motion and strategically designed agitator blades help in achieving a well-mixed and homogeneous concrete mixture, which is essential for producing high-quality and durable concrete structures.

- Q: Are there any specific guidelines for the installation of hopper components or agitators in concrete pump spare parts?

- Concrete pump spare parts have specific guidelines for the installation of hopper components and agitators. These guidelines aim to ensure the equipment's proper functioning and safety. Here are some key guidelines to consider: 1. Manufacturer's instructions: Carefully read and understand the manufacturer's instructions for installing hopper components and agitators. These instructions provide specific details and steps for installation. 2. Use the right tools: Utilize appropriate tools and equipment as recommended by the manufacturer. This includes employing the correct size wrenches, bolts, and other necessary tools for the installation process. 3. Clean and level surface: Prior to installation, ensure the surface is both clean and level. This promotes proper alignment and functioning of the parts. 4. Check for damages or defects: Conduct a thorough inspection of the hopper components and agitators for any damages or defects prior to installation. If any issues are found, address them before proceeding with the installation. 5. Align and position correctly: Adhere to the manufacturer's recommendations for aligning and positioning the hopper components and agitators. Improper alignment may result in malfunctioning or premature wear of the parts. 6. Secure all connections: Ensure that all connections, such as bolts, nuts, and clamps, are securely fastened according to the manufacturer's instructions. Loose connections can lead to accidents or damage to the equipment. 7. Test the equipment: After installation, it is crucial to test the equipment to ensure proper functioning. Follow the manufacturer's guidelines for testing and make any necessary adjustments if required. 8. Regular maintenance and inspection: Once the hopper components and agitators are installed, it is vital to regularly inspect and maintain them. This includes cleaning, lubricating, and replacing any worn-out parts as recommended by the manufacturer. By adhering to these guidelines, you can ensure the correct installation of hopper components and agitators in concrete pump spare parts, promoting efficient operation and prolonging the equipment's lifespan.

- Q: How often should concrete pump pressure gauges be inspected and replaced?

- Regular inspections of concrete pump pressure gauges are necessary to ensure they are accurate and functioning properly. The frequency of inspections and replacements may vary depending on the specific conditions and usage of the pump. However, it is generally recommended to inspect and replace pressure gauges at least once a year or after every 500 pumping hours, whichever comes first. This regular schedule helps prevent any potential accuracy or functionality issues that could impact the safety and efficiency of the pumping operations. It is also essential to adhere to the manufacturer's recommendations and guidelines for pressure gauge maintenance and replacement to maintain optimal performance and longevity.

- Q: How can a malfunctioning control box affect the pump's operation?

- A malfunctioning control box can have various negative effects on the operation of a pump. Firstly, it can result in an inaccurate or inconsistent control of the pump's functions. This means that the pump may not start or stop at the desired times or operate at the correct speed, leading to inefficient or inadequate pumping. Additionally, a malfunctioning control box may cause electrical issues, leading to power fluctuations or even power surges. These electrical problems can cause damage to the pump's motor or other components, leading to premature wear and tear or complete failure. Furthermore, a malfunctioning control box can also disrupt the communication between the pump and other systems. This can affect the pump's ability to receive or send signals, resulting in a lack of coordination with other equipment or systems that rely on the pump's operation. This lack of coordination can lead to system failures or disruptions in the overall process or operation that the pump supports. In summary, a malfunctioning control box can have detrimental effects on the pump's operation including inaccurate control, electrical issues, and disruption of communication with other systems. It is crucial to regularly inspect and maintain control boxes to prevent these malfunctions and ensure the reliable and efficient operation of pumps.

- Q: How to calculate the power of concrete pump motor?

- First of all, the length of the pipe and pipe diameter and the motor power is basically nothing to do!

- Q: How do I properly maintain and replace hydraulic motors in concrete pump spare parts?

- To ensure smooth operation and long-lasting performance of concrete pump spare parts, it is crucial to properly maintain and replace hydraulic motors. Here are some effective steps to guide you: 1. Regularly inspect the hydraulic motors to detect any signs of wear, damage, or leaks. Ensure the fluid levels are at the recommended levels. 2. Keep the hydraulic motors clean by removing dirt, debris, and contaminants. This prevents overheating and minimizes the risk of internal component damage. 3. Follow the manufacturer's recommendations and regularly check and change the hydraulic fluid. Clean and replace filters to prevent damage-causing particles. 4. Lubricate the hydraulic motors according to the manufacturer's instructions. This reduces friction and wear on moving parts, improving overall performance and lifespan. 5. Operate the concrete pump within the recommended load and pressure limits specified by the manufacturer. Excessive pressure or overloading can stress the hydraulic motors, leading to premature failure. 6. Keep track of the service life and usage of hydraulic motors. Over time, they may become less efficient. Promptly replace them to avoid disruptions to concrete pumping operations. 7. If unsure about maintenance or replacement, seek professional assistance. Professionals have the expertise to carry out tasks correctly, ensuring safety and optimal performance of concrete pump spare parts. By following these steps, you can effectively maintain and replace hydraulic motors in concrete pump spare parts, ensuring equipment longevity and efficiency.

- Q: Can concrete pump spare parts be repaired on-site, or should they be sent to a specialized repair facility?

- Concrete pump spare parts can be repaired on-site in certain cases, while in others it may be necessary to send them to a specialized repair facility. The decision of whether to repair on-site or send for specialized repair depends on the nature and complexity of the repair required, the availability of skilled technicians and equipment, and the time constraints of the project. In many cases, minor repairs or replacements of simple components can be carried out on-site. These may include tasks such as replacing hoses, seals, or filters, which can be done quickly and easily with basic tools and equipment. These types of repairs can often be performed by the operators or maintenance personnel themselves, without the need for specialized technicians. However, for more complex repairs or replacements, it is advisable to send the spare parts to a specialized repair facility. This is particularly true for critical components such as hydraulic cylinders, valves, or control systems, which require specialized knowledge and expertise to repair properly. Specialized repair facilities have trained technicians who specialize in specific equipment and are equipped with the necessary tools and resources to diagnose and fix complex issues. Moreover, specialized repair facilities often have access to a wider range of spare parts and can source genuine parts from the original manufacturer. This ensures that the repaired spare parts are of high quality and compatible with the specific make and model of the concrete pump. Additionally, these facilities may offer warranties on their repairs, providing peace of mind to the equipment owners. Ultimately, the decision to repair on-site or send for specialized repair depends on the specific situation and resources available. It is important to assess the complexity of the repair, the availability of skilled technicians, and the potential impact on the project timeline before deciding on the most appropriate course of action.

Send your message to us

PUMPING CYLINDER(SANY ) I.D.:DN230 CR. THICKNESS :0.25MM-0.3MM LENGTH:2146MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords