Pu Polyurethane Sandwich Panel for insulated panels price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Pu Polyurethane Sandwich Panel for insulated panels price

PU Sandwich Panel advantages

1. Effective insulation

The thermal conductivity coefficient of the rigid polyurethane(PU) foam can be 0.018-0.024 w/(m*k), which is only the half of expanded polystyrene(EPS), if its density is 38-42kg/m³. Rigid polyurethane foam is the best organic insulating material.

Since the thermal conductivity coefficient of the vesicant used is much lower than air, the insulating property of rigid polyurethane foam is better than rock wool, glass wool, expanded polystyrene and extruded polystyrene. Moreover, its insulating property can be sustainable for more than 30 years for its special closed-cell structure and resistance to gas diffusion.

2. Excellent corrosion and weather resistance

The polyurethane foam performs well in corrosion and weather resistance for its closed-cell structure and its surface material.

3. Moisture proof and waterproof

4. Anti freeze-thaw and sound absorption

The rigid polyurethane foam also performs well in anti freeze-thaw and sound absorption.

5. Energy efficiency and cost saving

Although the price is much higher than other alternatives, taking into account the excellent insulating property of the polyurethane foam, the increased costs will be offset by a substantial reduction in heating and cooling costs. Furthermore, we can reduce the thickness of external structure of the building by using thinner polyurethane foam to achieve the same insulating requirements, thereby increasing the indoor area.

6. Fireproof and high temperature resistance

Rigid polyurethane foam is a flame-retardant and self-extinguishing material after. It can reach a softening point of 250 degrees Celsius and decomposes at a higher temperature. A layer of carbon will be formed if it is lighted, which will effectively prevent the spread of the flame.

7. Anti-deformation and hardly to be cracked

The average life expectancy of rigid polyurethane foam can be more than 30 years under normal use and maintenance. It won’t be destroyed by fungi and algae growth, or rodents.

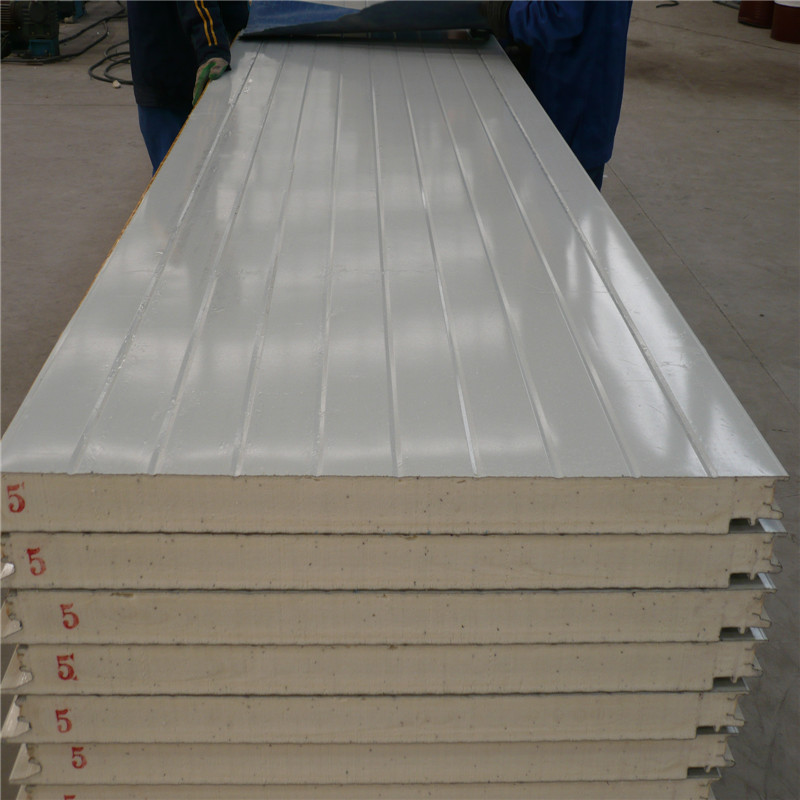

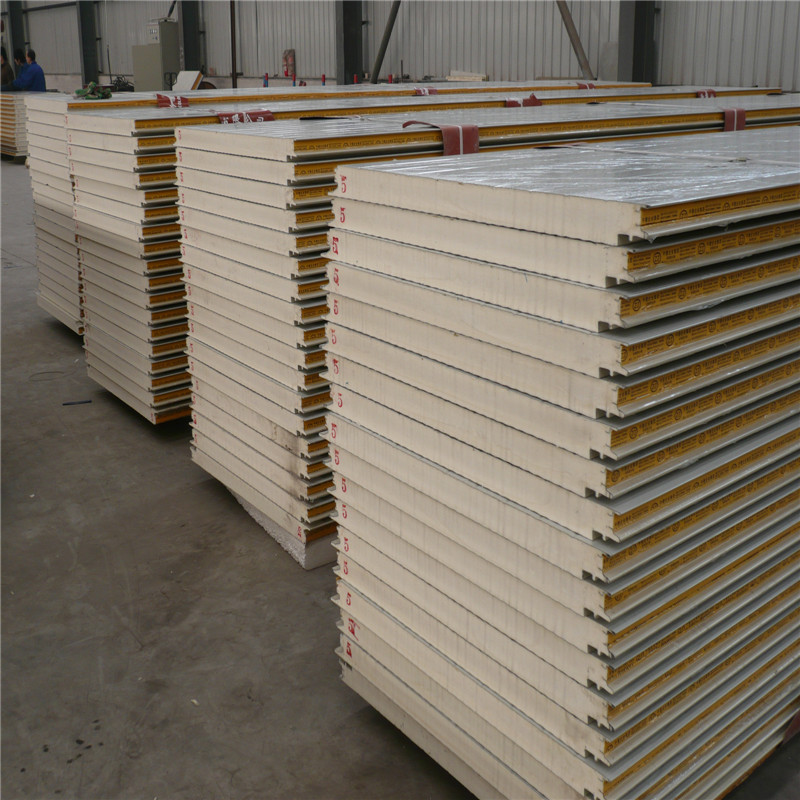

8. Beautiful appearance and easy installation

The polyurethane foam can be bonded with different surface materials, such as color steel plates, cement fiberglass cloth, aluminum, stainless steel and so on. So there are a lot of beautiful appearances and structures for customers’ choice according to their different specific requirements. It can be easily installed with fasteners because it is prefabricated in factory, which will significantly reduce the cost and shorten the schedule of construction.

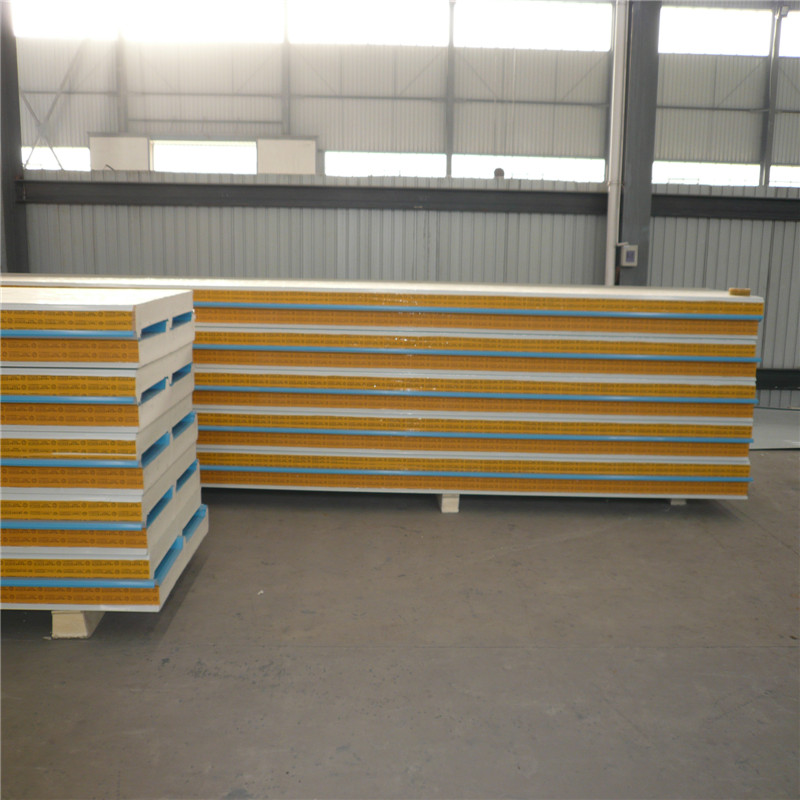

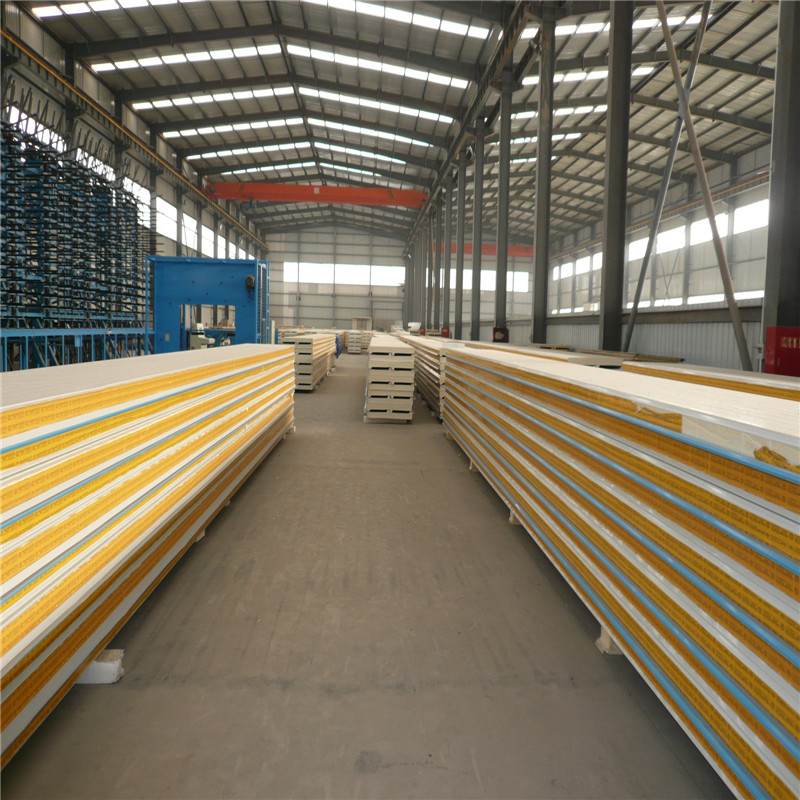

PU sandwich panels workshop

- Q: Tell us about the polyurethane sandwich panels, and how is its fireproof function?

- Polyurethane sandwich panel is a kind of new type of building material with hard foam polyurethane as sandwich material and color steel cover. It is by the pressure plate, polyurethane insulation materials, under pressure from the composition of the plate together. Polyurethane energy-saving board for the roof tilt of 3% of the class of industrial and commercial buildings, self-cleaning high-grade panel, reducing the amount of roof ash, so that the building roof to maintain long-term crystallization, high crest to improve the carrying capacity of the roof, Large, fast drainage, easy installation and other characteristics, lap at the use of fluid mechanics design to ensure the installation of fast, airtight, anti-capillary water seepage effect. Polyurethane insulation board has a good insulation, heat insulation, noise effects, and polyurethane does not help combustion, in line with fire safety, fire level can reach B level, very suitable for all types of industrial plants, civil construction and public buildings such as steel Bearing roofing.

- Q: Flammable and toxic "" "", how long life?

- Some polyurethane foam, some polystyrene foam. Non-toxic Flammable or not depends on the production of the time there is no plus flame retardant, the general GB is required B1 level, and non-flammable. Life expectancy, three to five years can certainly use = =

- Q: EPS sandwich panel metal panel thickness requirements

- Generally see the customer's request, the steel from 0.2-1.2MM have, the general 0.4 up and down the most

- Q: What is the rigid polyurethane sandwich panel

- This is a Caigang sandwich panel, can be used as a roof structure of the roof and wall panels, with a large stiffness, than the pressure plate stiffness, thermal performance is also very good, and the polyurethane sandwich panel fire Performance is also good

- Q: What brand of rock wool sandwich board is good

- In the country, only the Roxul rockwool ? and Paroc brand sandwich panels are the best; Other domestic brands, in fact, can be seen directly from the sample.

- Q: anxious! Will the polyurethane sandwich panels of various parameters, plant design!

- Polyurethane is a two-component AB material (isocyanate and combined polyether) mixed foam, is the thermal insulation material in the lowest thermal conductivity of 0.017 ~ 0.024 (thermal conductivity of the lower the better insulation). Polyurethane sandwich panels used in the filling process of polyurethane, pre-made pre-insulation board directly installed on-site use. If your plant area is relatively large, it is recommended that you only use the whole color plate, and then use the field of polyurethane spray foam process, this process than the infusion process is the advantage of spraying seamless, better insulation. The cost is still lower than the infusion process.

- Q: 3 side of the wall surrounded by color steel ~ the other side of the water ~ Will the three sides with the wall of the gap how waterproof ~

- You can try asphalt! Is the kind of paving the way! Very useful!

- Q: So here's the deal, I really need to run the oven cleaner, and I know how much smoke will come out of the oven, and I have a wired smoke alarm directly above the stove (landlord's design not mine). If I cover it with a sandwich bag, will that slow down the chance of it going off or increase the chance? Yes I know to remove the bag directly after the oven cleaner is done for obvious saftey reasons.

- Yes, bagging it will prevent tripping the alarm unless it is a tamperproof model. I used to install fire protection systems in hospitals and schools and we would put a baggie with a string attached to each detector so they did not trip from dust and welding smoke during copnstruction operations. Once the job was complete and the building was cleaned up we would walk through and pull off the plastic. Wrap a rubber band around the baggie so it stays snug. You can also avoid the tripping by opening a window near the stove and putting a fan in it as well as turning on the stove exhaust fan if you have one.

- Q: Steel structure, activities, such as sandwich panels board generally what kind of self-tapping screws fixed ah?

- Self-tapping screw, the English name Self-tapping Screw is a metal or non-metallic materials in the pre-drilling hole in the self-drilling with a female thread with a threaded fastener. Self-tapping screws are used for connection between thin metal plates (steel plates, saw boards, etc.). When connecting, first thread the bottom of the connector, and then screw the tapping screw into the threaded bottom hole of the connected part. As the tapping screw thread surface has a high hardness (≥ 45HRC), can be connected to the threaded bottom hole in the internal thread, thus forming a connection.

- Q: What is the polyurethane sandwich board material

- Double-sided color steel, the middle of the polyurethane sandwich composite panels Generally used in the roof of the building roof, the board has a good insulation, heat insulation, noise effects, and polyurethane does not help combustion, in line with fire safety. Upper and lower board plus the common role of polyurethane, with high strength and stiffness, the lower plate smooth and smooth, clear lines, increase indoor aesthetics, flatness. Easy installation, short duration, beautiful, is a new type of building materials.

Send your message to us

Pu Polyurethane Sandwich Panel for insulated panels price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords