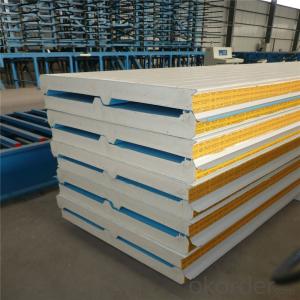

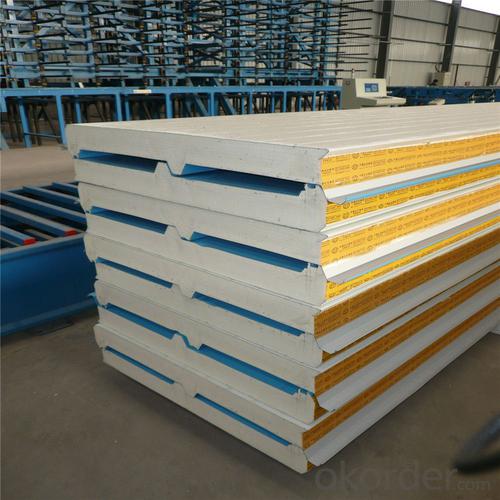

Low cost Pu Polyurethane Sandwich Panels

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Low cost Pu Polyurethane Sandwich Panels

PU Sandwich Panel advantages

1. Effective insulation

2. Excellent corrosion and weather resistance

3. Moisture proof and waterproof

4. Anti freeze-thaw and sound absorption

5. Energy efficiency and cost saving

6. Fireproof and high temperature resistance

7. Anti-deformation and hardly to be cracked

8. Beautiful appearance and easy installation

Building function:We will recommend the proper panel type and the best technical solution for you according to it

Fire resistance requirement standard of the project

Panel specification: Length*Wide*Thickness, peak height

Types of core material for your choice: PUR and PIR, EPS, rock wool, glass wool

Density: by your requirment

Surface material:prepainted steel plate

Panel color:For special colors, sample panels are negotiable

Coating type: Polyester type(PE), silicone modified polyester type(SMP), highly weather-resistant type(HDP) and fluorocarbon type(PVDF)

Surface profile:Ripple , plat , relief and square wave.

Steel sheet thickness:0.3-0.8mm

Steel sheet treatment:hot dip galvanized, Al-Zn coated

Manner of packing

Lead time

Applications of PU sandwich panel

PU Sandwich panels cover all applications in steel building construction and prefabricated houses: external walls, roofs, partitions, ceiling panels, acoustic sandwich panels forworkshops,warehouse,cold room, industrial factory buildings, office buildings, stadiums, villas, and public buildings, etc.

Our project cases with PU sandwich panels

Workshops

Houses in Australia

- Q: What is the acceptance criteria for rock wool sandwich panels?

- 1) upper and lower surface: the use of galvanized color steel plate, the thickness of 0.4-0.8mm. According to the specific requirements of customers, can also be used galvanized steel or galvanized steel plate. The steel plate is first molded by a molding machine and is compounded with the rock wool factory. ? 2) Yanmian core material: the use of density of 120kg / m yan rock block staggered laying, the fiber perpendicular to the sandwich plate on the upper and lower surfaces, and close contact to enrich the sandwich panel of the entire vertical and horizontal. The combination of rock wool and rock wool and the upper and lower steel plates through the high-strength foaming agent to form a whole, sophisticated production process to ensure that the high-density rockwool insulation and metal plate between the inner wall can produce poles Strong adhesion, so that the rock wool sandwich panel has a very good stiffness. ? Wujiang City Linxue purification Choi Board Co., Ltd. is the China Electronics Society Clean Technology Branch members. Commitment to various types of purification decoration, clean air-conditioning works, hydropower engineering facilities supporting the design, installation, commissioning through-train service.

- Q: And where are you? Will there be any differences in prices? I am Yuyao, Zhejiang

- 0.5 thick foam board 55 is certainly not buy, even if the real 55 is also cut corners, the basic price of 65 or so, excluding tax, if you want to pack the plate, then more expensive. There is the roof, then the general use of corrugated board, the price is higher. Between 72-75, look at the request. We are here in Suzhou. Can be contacted

- Q: Rock wool sandwich panel product parameters

- Upper / lower plate thickness 0.4 ~ 0.8mm color steel / electric, hot galvanized sheet / stainless steel plate Core (Mine) rock wool capacity of 120 ~ 150kg / m thickness: 50-150mm Side seal steel strip or no side seal steel strip : 0.4mm ~ 0.8mm galvanized sheet Effective width of the mouth 950mm, 1150mm; thickness 40mm ~ 150mm; length is not limited Board protection form PVC protective film

- Q: Who knows the standard of color steel composite panels which? No matter what kind of material sandwich layer, please know the knowledge of this person told me.

- 1. Light weight: 10-14 kg / square meter, equivalent to 1/30 of the brick wall. 2. Thermal insulation: core thermal conductivity: λ <= 0.041w / mk. 3. High strength: can be used for smallpox envelope structure bearing, bending compression; general housing without beams and columns. 4. Bright color: no surface decoration, color galvanized steel coating to maintain a period of 10-15 years. 5. Flexible installation: the construction period can be reduced by more than 40%. 6. Oxygen index: (OI) 32.0.

- Q: How to use the sandwich board to the concrete square column into a cylindrical and finishes are made of aluminum-plastic package, it is best to have pictures or drawings

- With a sandwich made of a semi-circular in the bottom of the column, the top and the middle of every 500 or so, with expansion bolts wooden side of the board will be fixed on the column, with a sandwich panel saw a narrow wood, Into a round wooden column of the pillars, and then stick to the aluminum plate.

- Q: Is the sandwich panel a mezzanine? What is the effect of painting? How long can I use life on the cabinet? Best example! My house in the decoration What is the cost of a sheet plus paint? Will the board be put on the floor after painting and painting?

- Sandwich panels do not refer to blockboards, because the sandwich panels are many kinds, including three PCT board, five PCT board, nine PCT board ... ... can only say that the blockboard is a kind of sandwich panels. Not directly in the blockboard on the paint, usually on the outside to paste decorative panels, and then clear oil process, if you want to paint directly on the plate, please use medium density board, used for making furniture, oil mixing process! Maintenance is good, life is not a problem! But can buy as much as possible to buy, do not live production. After all, the scene can not reach the factory clean paint, and did not sell the beautiful. ???? The general plate is not very expensive, but do not underestimate the paint! Will the board be put on the floor after painting and painting? The answer is yes, the plate had to nail a layer of gypsum board, and then putty putty paint, so that will not be delaminated.

- Q: Steel structure, activities, such as sandwich panels board generally what kind of self-tapping screws fixed ah?

- Steel structure, activities board room sandwich panel tapping screw selection: Roof: 7.5cm with 135 self-tapping nails; 10cm with 165 self-tapping nails. Wall board 5cm with 75 self-tapping screws; 7.5cm with 100 self-tapping nails; 10cm with 125 self-tapping nails

- Q: Use the foam color steel sandwich panel after decoration

- Paste the wallpaper, polystyrene foam board - also known as foam color steel sandwich panels, EPS board is containing volatile liquid blowing agent of the polystyrene beads, heated by heating in the mold after heating It is mainly used in building wall, roof insulation, composite board insulation, cold storage, air conditioning, vehicle, ship insulation, floor heating, decorative carving and other uses are very extensive. Wallpaper, also known as wallpaper, wall cloth, is a wall for the interior decoration materials, widely used in residential, office, hotels, hotel interior decoration. Material is not limited to paper, but also contains other materials. Because of the colorful, rich patterns, luxurious style, safety and environmental protection, construction convenience, affordable and other kinds of other interior materials can not match the characteristics, so in Europe and the United States, Japan and other developed countries and regions have been a considerable degree of popularity. Wallpaper is divided into many categories, such as film wallpaper, coated wallpaper, embossed wallpaper and so on. Usually with bleached chemical pulp production of base paper, and then by different processes of processing, such as coating, printing, embossing or surface coating, and finally by cutting, packaging after the factory. Has a certain strength, toughness, beautiful appearance and good water resistance.

- Q: Color steel sandwich board glue is a mixture of vinyl and white plastic, resulting in a chemical reaction caused by sticky. Does anyone know the chemical name of black gelatin? Vinyl are basically imported, and that how is the deployment of white plastic? Is the sandwich used in the sandwich plate diluted? That color steel PU foam with the glue is not the same black and white glue generated reaction? Hope to receive professional mention.

- Vinyl for the polymerization of isocyanate components, and now the domestic is also good, white plastic for the polyol component, the formula I know

- Q: We are the construction unit to the scene into the decoration with the sandwich panels and fire retardant coating supervision requirements were re-test and then also use a good brush-resistant paint sandwich panels to do re-examination Will this want to detect what the purpose of what is the detection of the project. Good people to help answer Thank you

- Testing items, the general requirements in the relevant norms, if there is no required material, you can not do the retest.

Send your message to us

Low cost Pu Polyurethane Sandwich Panels

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords