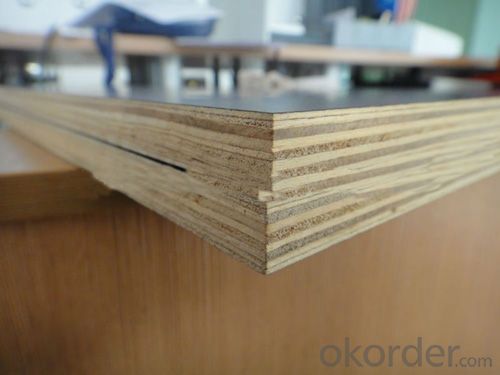

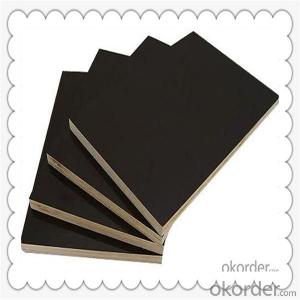

Brown or Black Film Faced Plywood with High Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 4500 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Details:

Plywood is a sheet material manufactured from thin layers or "plies" of wood veneer that are glued together with adjacent layers having their wood grain rotated up to 90 degrees to one another. It is an engineered wood from the family of manufactured boards which includes medium-density fiberboard (MDF) and particle board (chipboard). The surface is natural or engineered veneer.

· Type: Plywoods

· Place of Origin: Shandong, China (Mainland)

· Model Number: Plywoods

· Usage: Outdoor

· Grade: First-Class

· Main Material: Poplar, Poplar

· Formaldehyde Emission Standards: E2

· Plywood Type: 9-Ply Boards

· Thickness: 18mm

· Moisture: 10%

· Standard Size: 1220x2440mm,1250x2500mm

· Glue: Melamine WBP,Phenolic WBP

· Film: Brown,Red,Black

· Cycle Life: about 6~10 repeated using times

· Item: Shuttering plywood

· Capacity: 4500cbm/month

Packaging & Delivery:

Packaging Details: | Inner packing: Wrapped with 0.2mm plastic bag Outer packing: Pallets are covered with 2.0 mm plywood and then steel tape for strength. |

Delivery Detail: | within 15 days after order confirmed |

Product Description:

18mm waterproof shuttering plywood for construction

Product Name | Shuttering plywood |

F/B | Black film, brown film, anti-slip film |

Grade | First-class |

Core | Poplar, hardwood, birch, pine, combi , and so on |

Glue | MR WBP |

Thickness | 9mm 12mm 15mm 18mm 21mm |

Specification | 1220x2440mm, 1250x2500mm, |

Moisture Content | 8-13% |

Package | Standard export package on pallet |

Certification | ISO9001 |

MOQ | 1x40HQ |

Price Terms | FOB,CIF,CNF |

Payment | T/T, 100% irrevocable LC |

Delivery Time | Within 15 days after order confirmed |

Supply Capacity | 4500CBM/month |

Usages | Can be widely used for building concrete, etc |

Remarks | Top class equipment with top class produce technique Credit first, fair trading |

Thickness Tolerance:

Thickness less than 7mm:tolerance+/-0.2~0.3mm

Thickness 7~21mm:tolerance+/-0.4~0.5mm

Packing Detail: Inner packing: Wrapped with 0.2mm plastic bag Outer packing: Pallets are covered with 2.0 mm plywood and then steel tape for strength.

Product Pictures:

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some wood products according to customers request?

A4: Yes, we can produce wood products according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

- Q: Rock wool sandwich board Yanmian generally what brand, quality Zeyang?

- We are all with a small factory rock wool, we do not know the manufacturers, but this thing is too much pollution

- Q: Which master asked me how to deal with the leakage of rain, worry about me

- Color steel sandwich panels: 1. Corrugated sandwich board may be in the fixed when the nail is too tight lead to corrugated subsidence, the formation of small puddles, it will leak, the solution with mildew copper phosphate repair. 2. Flat sandwich plate may be due to the possibility of two plates of the gap between the edge of the gap is not enough height, the general rain is no problem, the rainfall is large, the solution is to increase the height of the edge fold (the cost of repair each gap about 15 yuan about). Also do not understand can ask!

- Q: What is the difference between a rock wool sandwich panel, an EPS sandwich panel and a polyurethane sandwich panel?

- 1, different fire rating: Yanmian sandwich panels for the A-level, EPS for the B3-class, polyurethane B1 level. 2, different insulation properties: the three polyurethane sandwich panels the best. 3, waterproof performance is different: the three polyurethane and EPS better than rock wool. 4, the density is different: rock wool bulk density is generally 120KG / cubic meter, EPS is generally 16, polyurethane is generally 40. All in all, the overall performance of polyurethane sandwich panels for the best, is the best choice for steel structure enclosure!

- Q: Color steel sandwich panel prices

- To see where you use, this thing price fluctuation range i relatively large

- Q: What are the benefits of rock wool sandwich panels and what are the advantages?

- Thermal insulation, construction is simple. But the relative cost is higher,

- Q: Color plate sandwich panel 75mm, 0.

- The 75MM is the insulation thickness of the insulation board .050MM is the thickness of the insulation board with the color of the plate, the professional point should be called on the next 5, or what, is the top of the top plate thickness, the next is the next look at the house To the thickness of that side If you are the wallboard, that is, two sides are flat look, 0.50 is a side of the color plate thickness, usually outside the house to see that side, the house did not explain the thickness of the normal and outside the same thickness, Hope you can see,

- Q: Explosion-proof rock wool sandwich panel how to do waterproof

- Do a good job of waterproof coating treatment, the other is, you can in its surface, composite layer of metal, so you can better waterproof moisture Oh.

- Q: Span 13 meters of the roof beam how to do the roof with 75mm foam sandwich board does not consider the wind load (indoor)

- We have a home here Jiangxi Baoyuan Caigang, they specializing in the production of sandwich panels, activities, color steel tiles, galvanized sheet, C steel, steel industry in the color of the very experienced, Jiangxi Baoyuan Caigang products sell well throughout the country , Won the majority of customers praise.

- Q: Do the closet with a sandwich board? Or with a MDF good?

- Good with sandwich panels

- Q: How to use the 0.3x50 sandwich panel to do a hundred square meters of roof to install how much money? Guanzhong area.

- Color steel tile anti-rust ability is very strong, you can contact [Baoyuan Steel Structure Department], we know what material is good, the price to electricity-based.

Send your message to us

Brown or Black Film Faced Plywood with High Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 4500 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords