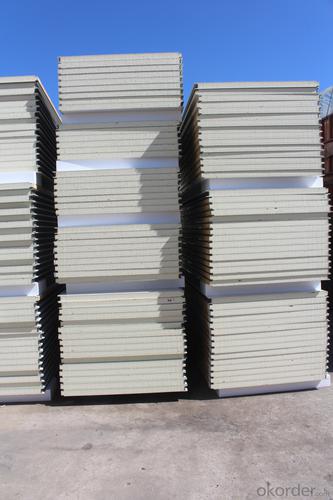

Cheap High Quality PU Polyurethane Sandwich Wall Panels

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Cheap High Quality PU Polyurethane Sandwich Wall Panels

Features:

1. Quick Details

Australian Standard 75 MM PU Sandwich Wall Panels

| Standard: | Grade: | Place of Origin: | |||

| Brand Name: | Technique: | Surface Treatment: | |||

| Width: | Length: |

2. Packaging & Delivery

| Packaging Detail: | standard seaworthy packing |

| Delivery Detail: | 25 days |

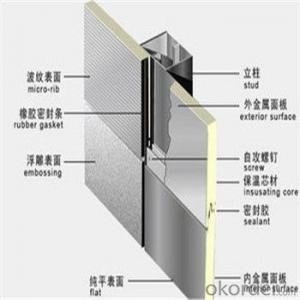

3. Specifications

1.for civil building, car port, roofing, shelters, walk ways, fences & barns.

2. anti-rust.

3.good quality&service.Colored Corrugated Galvanized Steel EPS Sandwich Wall Panels

Advantage

Great Appearance

Affordable

Lightweight

Great Durability

Low Maintenance

Easily installed over Existing Roofing

Energy Efficient

Resists Mold & Mildew

Non-Combustible

15--30 Year Finish Warranty

100% Recyclable

Raw materials

(1)Hot dipped galvanized steel sheet

(2)color coated galvanized steel sheet

(3)Galvalume steel sheet

(4)Pre-painted galvalume steel sheet

(5)Aluminum sheet

(6) Pre-painted aluminum sheet

(7)Stainless steel sheet

Applications

(1) Gymnasium

(2) Warehouse

(3) Hospital

(4) Supermarket

(5) Shelter,

(6) Commercial facilities

(7) Industrial facilities

(8) Garage

- Q: What are the advantages of nylon plates compared to other plastic sheets?

- The nylon series is the most important engineering plastic. The product is widely used, covering almost every area, is the five most widely used engineering plastics varieties Nylon board according to the production process is divided into two kinds of extrusion and casting. Extrude the nylon plate 1, nylon 6 (white): The material has the most comprehensive performance, including mechanical strength, stiffness, toughness, mechanical shock absorption and wear resistance. These features, coupled with good electrical insulation and chemical resistance, make nylon 6 a "universal grade" material for the manufacture of mechanical structural parts and maintainable parts. 2, nylon 66 (cream): Compared with nylon 6, its mechanical strength, stiffness, heat and wear resistance, creep resistance better, but the impact strength and mechanical damping performance degradation, very suitable for automatic lathe Machining. 3, nylon 4.6 (reddish brown): Compared with ordinary nylon, nylon 4.6 is characterized by strong rigid retention, good creep resistance, in a wide temperature range, more heat aging, therefore, nylon 4.6 for Nylon 6, nylon 66, POM and PET in the stiffness, creep resistance, heat aging, fatigue strength and wear resistance can not meet the requirements of the "higher temperature field" (80 -150 ℃) 4, nylon 66 + GF30 (black): Compared with pure nylon 66, this nylon filled with 30% glass fiber reinforced, its heat resistance, strength, stiffness. Creep resistance and dimensional stability, wear resistance and other properties have improved, it is the maximum allowable use of high temperature. 5, nylon 66 + MOS2 (gray black): This nylon filled with molybdenum disulfide, compared with nylon 66, its rigidity, hardness and dimensional stability has improved, but the impact strength has declined, molybdenum disulfide Of the grain formation effect to improve the crystal structure, so that the material bearing and wear resistance are improved.

- Q: How to identify the custom wardrobe or cabinet plate is large Asia E0 grade plate

- So to speak, and I do furniture in Guangzhou side, and now really did not hear anyone who has E0 plate. The The Including Europe, Sofia, hundreds of millions of home and other custom furniture are afraid to say that their sheet is E0, if you look at is not the original product, then look at the quality of the store and the template how much difference to know, the general And the store's model gap will not exceed 5%, if the details of the details of the gap is far away, needless to say, is certainly bought the local brand-name furniture ~

- Q: Which master please teach about aluminum alloy doors and windows under the material calculation method? Flattened; push-pull can be the best example. Thank you!

- High pressure water jet cutting High-pressure water jet cutting is the use of high-pressure cylinder to the ordinary tap water pressure to 250 ~ 400MPa, and then through the hole diameter of 0.15 ~ 0.35mm gem nozzle jet to form a speed of 800 ~ 1000m / s high-speed jet, and in the water arrow Add the right amount of sand used to cut all the hard and soft materials. The advantages of water cutting are: almost no heat when cutting, the product is not thermal deformation, can guarantee product size accuracy; slit narrow and smooth cutting surface, without secondary processing, improve production efficiency; water cutting can be good To solve some high melting point, alloy, composite materials and other special materials, cutting processing. However, due to water knife and water jaw lag and incision bevel phenomenon caused by the tolerance error, for more than a certain thickness (40mm or more) or high precision parts, the use of waterjet processing and can not achieve the best results.

- Q: Millennium boat plate fake, how to identify.

- The main board are: blockboard, finger board, fire board, multi-layer board, gypsum board, fire retardant board, decorative panels, the main board of the United States, Such as all kinds of sheet products to play, in the entire East China market share of small, with the brand increasingly mature, and launched the floor wood doors, paint glue, decorative hardware and other products.

- Q: Is the door frame, not the door sets. The The What are the materials used in the door frame?

- Door frame borders are mainly two kinds of wood, one pine, the second is the fir, the market with more fir, pine some expensive, pine nail force is better than fir. Useful MDF to do, grip nail force is poor, there is a multi-layer board, relatively less environmentally friendly, it is best to use solid wood to do the substrate and then a layer of 5 mm density, can never be deformed, never crack The quality requirements, the use of longer life.

- Q: Millennium mill plate is good or the new millennium plate is good

- The new millennium is the king coconut group under the well-known domestic brands, fame may not thousands of years of large, it is not wasting thoughts on the minds of the mind spent on the quality of the new millennium is not a brand of goods factory specializing in the production of this brand, the other It is not to say, buy bad also buy an OEM goods you injustice injustice, anyway, we are all with the new millennium, on their own home watching the factory getting bigger and bigger, we believe that seeing is believing , Listen to the evaluation of the workers inside.

- Q: Three thousand square plate is good?

- I think you still have to believe that a sub-quality goods, choose the plate, can not just look at the price, but also depends on the quality, reliable quality and stability to deal with home decoration. So I can only say that the home decoration or the need for an environmentally friendly space so I think the election three thousand square or value for money, specifically to see your needs!

- Q: PCB plate manufacturers are famous what

- Sunrise, Matsushita, Arlon, Nelco, Rogers, Tanconic, polyflon, etc.

- Q: PCB is used to do the PCB, but the middle of the PP material is dicyandiamide, black

- Refers to the surface is FR4 light green, the middle of the black plate

Send your message to us

Cheap High Quality PU Polyurethane Sandwich Wall Panels

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords