Phenolic HVAC air duct inslulation board

- Loading Port:

- Xiamen

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 80000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

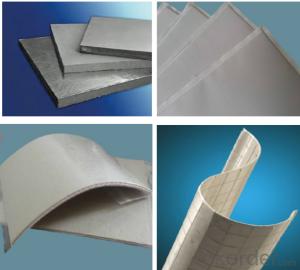

The Phenolic Foam Preinsulated Duct panel system is the most advanced and inovative energy saving system of centre air-conditioning ductwork available worldwide. The Ductwork is fabricated by using rigid phenolic insulation panels in length of 4m and provide the optimum energy saving and environmental solution in comparison with other types of ductwork. The system consists of Phenolic Pre-insulated Duct Panels, fabrication methods, jointing systems and a complete line of accessories to complete a system.

The Phenolic Foam Preinsulated Duct System is the recoganized leader in new generation pre-insulated ductwork. It offers the triple benefits to cut down the energy, carbon and cost whilst already having proved itself in its highly competitive marketplace. Being based on a phenolic resin it has outstanding fire resistance characteristics and extremely low smoke emission when expose to a flame source.

Parameters:

| Item | Unit | Specification |

| Panel Structure | Alu./Foam/Alu. | |

| Standard Panel Size | mm | 3950*1200*20 |

| Alu. Foil Thickness | mm | 0.04 |

| Foam Density | kg/m3 | 40 |

| Thermal Conductivity | w/m.k | 0.02 |

| Compressing Strength | Mpa | 0.25 |

| Bending Strength | Mpa | 1.2 |

| Combustibility Property | Class 0 (BS476 Part 6 & 7) | |

| Water Absorption | % | 1.9 |

| Max Smoke Density | % | 2 |

| Dimension Change | % | 0.3 |

| Ambent Temperature | °C | -250- +150 |

| Maximum Allowable Wind Velocity | m/s | ≤12 |

| Continuous Running Maximum Temperature | °C | ≤70 |

Advantages:

Compared to traditional insulated Sheet Metal Ductwork:

Do it in one time, no lag insulation required, save the labor and cost.

Save the buiding space due to good insulation function

Lightweight, decrease the total weight of building

Decrease air leakage by using flange joint

Low thermal conductivity, no condensation, energy saving

Closed cell foam, good acoustic insulation

Fire-resistance, no smoke when expose to fire

Faced with aluminum foil, it’s water proof and anti-microbial

CFC and HCFC free, environment friendly

Welcome to request at your any convenient time!

- Q: Have to know the holy spring Antwerp phenolic steel sandwich board how much money a square? I heard that the insulation effect is good, fire performance is also very good

- Phenolic insulation board a square 400 or so it Almost all of the price of phenolic need 50 points of oxygen was on fire, OKorder Zhongji machinery manufacturing phenolic insulation is the export, to the domestic sales a little less, you can order the next.

- Q: Whether the rock wool sandwich panel is environmentally friendly

- How to say this, the board itself is environmentally friendly, the production process is not environmentally friendly ~

- Q: Caigang glass wool cotton sandwich panels are non - burning materials do

- Caigang glass wool cotton sandwich panels are non-burning materials, Caigang glass wool sandwich panels and rock wool sandwich panels belong to the same fire board.

- Q: Housing ceiling with a good light or good sandwich panels

- Of course, light steel keel Well, first of all, wood keel easy to crack, deformation. Because the wood keel is not moisture, which easily lead to ceiling cracking, deformation, and easy to be corrosion, insects. In addition to the above problems, there are hidden dangers such as ceiling fall. Second, the wood keel strength and toughness is poor, resulting in the ceiling, partition wall life is short, and not fire, easily lead to fire. Light steel keel is a substitute for wood keel. Light steel keel with high strength, corrosion resistance, structural stability, easy to deformation and so on. Its flatness is better, the construction speed, good stability, as well as fire, moisture and other advantages, so, in order to renovate the dormant hidden, it is best to use light steel keel.

- Q: Activities of the sandwich board, the middle of the middle of the kind of foam, a square meter how much money? And how much is that one window? Is it aluminum? How much is the door? Fujian Nanping where cheaper, I was Shaowu's.

- 60--80 one meter aluminum alloy 100--120 door with the price I do not know I was Kyoto

- Q: Polyurethane sandwich panels polystyrene sandwich panels how to identify? 75 models Price / square?

- Polystyrene foam and foam polyurethane alone from the appearance is very easy to identify, the flammability of the former flammable and drip, the latter flame from the fire self-extinguishing and only carbonized insoluble drops. Density is also different, do not know what you mean 75 models. Price, then, the specific specifications of polyurethane color sandwich panels in general 120-170 range; if it is outside the wall insulation board, the price is generally ranging from 50-100.

- Q: Color steel sandwich panel prices

- Look at how much your pricing price ah

- Q: I need to install a circuit breaker and a few outlets on a container made with sandwich panels.Are there any special equipments or materials for the job?

- This is a tough one. You may have to use 2X4's to extend the wall inwards to allow for it. I attached a link that might help.

- Q: How to fix the color steel tile foam sandwich panel

- Selling sandwich board where there is a fixed code of small pieces sold with self-tapping screws to lock the general to another money

- Q: Color steel sandwich panels have what kind of ah?

- company's product: The company's main Caigang tiles, Caigang sandwich (rock wool, foam) insulation composite panels, car panels, frozen plate, C-steel purlins, municipal enclosures and other color steel products and its supporting various colors Steel accessories. The company's products are widely used in various industrial plants, clean room, cold storage, container-type mobile board room, fixed board room, canopy and a variety of building plus layer and other projects. Company purpose: The company promises to "handsome in appearance, reasonable structure, durable, low profit prices" with the majority of users wholeheartedly cooperation, join hands to create brilliant! Chongqing Caigang sandwich panel production

Send your message to us

Phenolic HVAC air duct inslulation board

- Loading Port:

- Xiamen

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 80000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords