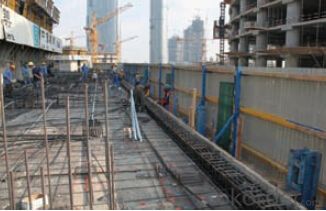

Protection Platform for Formwork and Scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Protection Platform PP-50

A kind of new type construction protection system, applying operating platform and safer job

location for construction corps.

Characteristics:

◆ Easy and quick assembling.

◆ Lifted as a group, it is rapid and economic.

◆ Auto-climbing

◆ A safe and reliable anchor system

1. Composition

2. Assembly process of anchor system

(1) Embed V-climbing cone and anchor plate into the slab.

(2) Fix anchor shoe on the slab by tensile bolt.

(3) The fixed anchor shoe.

◆ High work efficiency with work platform and unload platform

◆ High light transmittance with the hollow block

- Q: Can steel formwork be used for architectural concrete elements?

- Yes, steel formwork can be used for architectural concrete elements. Steel formwork is known for its durability, strength, and versatility, making it suitable for various construction applications, including architectural concrete elements. It provides a smooth and precise finish and can be easily customized to meet specific design requirements. Additionally, steel formwork is reusable, making it a cost-effective choice for architectural projects.

- Q: Are there any specific considerations for using steel formwork in earthquake-prone areas?

- Yes, there are specific considerations for using steel formwork in earthquake-prone areas. Steel formwork offers several advantages such as strength, durability, and reusability. However, it is crucial to ensure that the steel formwork is designed and constructed to withstand the seismic forces generated during an earthquake. The formwork system should comply with local building codes and regulations related to seismic design. It is also important to consider factors like steel quality, connection details, bracing systems, and anchorage methods to enhance the formwork's resistance to seismic loads. Additionally, regular inspections and maintenance of the steel formwork are necessary to ensure its integrity and effectiveness in earthquake-prone areas.

- Q: What are the common challenges when using steel formwork?

- Some common challenges when using steel formwork include its heavy weight, which can make transportation and handling difficult, the need for specialized equipment and skilled labor for installation and removal, the potential for corrosion if not properly maintained, and the higher initial cost compared to other formwork materials.

- Q: I was engaged in the patent agency, the two days of receipt of a patent application on the bridge, it is a drawing section map, the other nothing, no label no text, I am on mechanical, civil engineering drawings and utterly ignorant of ah, so simple, later on the Internet for a long time and recall ratio of patent it is unclear whether the drawings, sections of the box girder template, now the goal is clear, but a box girder template knowledge I don't know much about the Internet, did not find out what things, patent is only a few patents, I want to know more about the box girder and box girder template for example, the box girder template with cast-in-place prefabricated, full steel structure, steel wood structure, the hydraulic support system, but also ordinary (the ordinary I don't know what), etc. So, anyway, more detailed information as possible, thank you ~ ~ no more, I don't mind ah, not much, have a point with the province oh

- Especially for the construction of large bridges, the construction method of ten million, who is the way to think, who will make money in this regard. Therefore, this patent product is spent on the work of people's minds, before the patent application is not approved, is not willing to disclose to others.

- Q: How does steel formwork contribute to the overall structural stability of the building?

- Steel formwork contributes to the overall structural stability of a building in several ways. Firstly, it provides a strong and rigid framework that supports the weight of concrete during the pouring and curing process. This ensures that the concrete is evenly distributed and prevents any sagging or deformation. Secondly, steel formwork helps in maintaining the desired shape and dimensions of the concrete elements, such as columns, beams, and walls, which are crucial for the overall stability of the structure. Additionally, steel formwork offers high tensile strength and durability, allowing it to withstand the forces imposed by the concrete and any external loads, thus enhancing the structural integrity of the building.

- Q: How does steel formwork contribute to the overall sustainability of the project?

- Steel formwork contributes to the overall sustainability of a project in several ways. Firstly, steel formwork is a durable and long-lasting material, which reduces the need for frequent replacement and minimizes waste generation. Additionally, it can be easily disassembled and reused in multiple construction projects, reducing the demand for new materials and minimizing the environmental impact. Steel formwork also provides excellent strength and stability, allowing for efficient and accurate construction, which in turn reduces construction time and energy consumption. Overall, the use of steel formwork promotes sustainable practices by reducing waste, conserving resources, and enhancing construction efficiency.

- Q: How does steel formwork handle concrete curing?

- Steel formwork is widely chosen for concrete construction because of its durability and strength. When it comes to concrete curing, steel formwork offers several advantages. First and foremost, steel formwork ensures excellent support and stability for the concrete during the curing process. With its rigid structure, it guarantees that the concrete maintains its desired shape and form, preventing any deformations or bulges. This is especially important for projects that require precise dimensions or intricate designs. Secondly, steel formwork has good heat conductivity, enabling efficient heat dissipation during concrete curing. This is beneficial as it helps regulate the concrete's temperature, preventing excessive heat buildup that could result in cracks or other structural issues. Steel's ability to dissipate heat quickly also accelerates the curing process, reducing the overall time required for the concrete to achieve its desired strength. Moreover, steel formwork can withstand the high pressures exerted by the wet concrete during the curing phase. Its robust nature ensures that it remains intact and doesn't deform or buckle under the weight of the concrete, maintaining its structural integrity throughout the process. Additionally, steel formwork is reusable, making it a cost-effective option for concrete curing. Once the concrete has cured and hardened adequately, the formwork can be easily removed, cleaned, and reused for future projects. This eliminates the need for frequent formwork replacements and reduces construction waste. In conclusion, steel formwork is an ideal choice for concrete curing due to its stability, heat conductivity, strength, and reusability. It provides excellent support, regulates temperature, withstands high pressures, and offers cost savings. These characteristics make steel formwork a reliable and efficient option for ensuring successful concrete curing in construction projects.

- Q: How does steel formwork handle concrete curing additives?

- Due to its durability and strength, steel formwork is a popular option for concrete construction. It is highly compatible with concrete curing additives and can effectively handle their use. Concrete curing additives, such as accelerators or retarders, are utilized to modify the setting and hardening time of concrete. These additives are typically incorporated into the concrete mixture during the mixing process or applied to the formwork surface prior to pouring the concrete. The presence of curing additives in the concrete does not negatively impact steel formwork. It is resistant to chemical reactions and can withstand potentially corrosive additives. This guarantees that the steel formwork remains structurally sound and maintains its integrity throughout the concrete curing process. In addition, steel formwork provides a smooth and non-porous surface, which allows for easy application and penetration of curing additives. This facilitates the uniform distribution of additives across the concrete surface, promoting consistent curing and optimal strength development. Furthermore, steel formwork can be reused, making it suitable for multiple concrete pours. This reusability is particularly advantageous when working with concrete curing additives, as the formwork can be easily cleaned after each use. This ensures that no residue or accumulation of additives remains on the surface, preventing any potential interference with subsequent concrete pours or compromising the quality of the cured concrete. In conclusion, steel formwork is well-suited for handling concrete curing additives. Its resistance to chemicals, smooth surface, and reusability make it an ideal choice for accommodating the use of curing additives, ensuring efficient and effective concrete curing.

- Q: What are the different safety features incorporated in steel formwork systems?

- Steel formwork systems are designed with various safety features to ensure the protection of workers and the overall success of construction projects. Some of the key safety features incorporated in these systems include: 1. Sturdy Construction: Steel formwork systems are made of high-quality steel materials, which provide strength and stability. This robust construction minimizes the risk of collapse or structural failure, ensuring the safety of workers. 2. Adjustable Support Systems: Steel formwork systems are equipped with adjustable support systems, such as props and jacks. These features allow for precise adjustment and leveling, ensuring stability and preventing the formwork from shifting or collapsing. 3. Guardrails and Toe Boards: Steel formwork systems often include guardrails and toe boards as standard safety features. These prevent workers from falling off the edges of the formwork, reducing the risk of accidents and injuries at height. 4. Non-Slip Surfaces: To enhance safety, steel formwork systems are often designed with non-slip surfaces. These surfaces provide better traction and reduce the likelihood of workers slipping or falling, especially in wet or slippery conditions. 5. Safety Accessories: Many steel formwork systems come with additional safety accessories, such as safety nets, harnesses, and personal protective equipment (PPE). These accessories provide further protection for workers, preventing falls and ensuring compliance with safety regulations. 6. Easy Assembly and Dismantling: Steel formwork systems are designed to be easily assembled and dismantled, reducing the time workers spend at height. This minimizes the risk of accidents during construction and promotes efficient workflow. 7. Fire Resistance: Steel formwork systems are often fire-resistant or fire-retardant, enhancing safety in case of fire emergencies. This feature helps to prevent the rapid spread of fire and provides additional time for evacuation or firefighting. 8. Load-Bearing Capacity: Steel formwork systems are engineered to have high load-bearing capacities, allowing them to support heavy concrete loads. This ensures that the formwork can withstand the weight without deformation or failure, enhancing safety during construction. In conclusion, steel formwork systems incorporate various safety features to protect workers and ensure the successful completion of construction projects. From sturdy construction and adjustable support systems to guardrails and non-slip surfaces, these features prioritize worker safety and contribute to a safer working environment.

- Q: What is the weight of steel formwork?

- The weight of steel formwork can vary depending on several factors such as the dimensions and thickness of the steel panels, the type and arrangement of supports, and any additional reinforcements or attachments. Generally, steel formwork panels can range from around 20 to 40 kilograms per square meter. However, it is important to note that these figures are approximate and may differ based on the specific design and specifications of the steel formwork being used.

Send your message to us

Protection Platform for Formwork and Scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords