Protection Platform for Formwork and Scaffolding systems

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

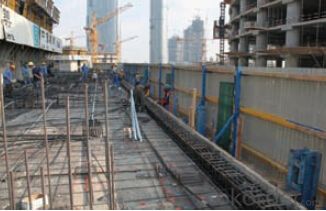

Protection Platform PP-50

A kind of new type construction protection system, applying operating platform and safer job

location for construction corps.

Characteristics:

◆ Easy and quick assembling.

◆ Lifted as a group, it is rapid and economic.

◆ Auto-climbing

◆ A safe and reliable anchor system

1. Composition

2. Assembly process of anchor system

(1) Embed V-climbing cone and anchor plate into the slab.

(2) Fix anchor shoe on the slab by tensile bolt.

(3) The fixed anchor shoe.

◆ High work efficiency with work platform and unload platform

◆ High light transmittance with the hollow block

- Q: How does steel formwork handle formwork removal and storage?

- The durability and strength of steel formwork make it highly suitable for the removal and storage of formwork. When it comes to removing formwork, steel formwork can be easily taken apart and removed from the concrete structure. This is mainly because steel formwork is modular, making it easy to dismantle and reassemble. Steel formwork systems often consist of standard-sized panels that can be quickly and efficiently removed by loosening the connecting bolts or clips. This ensures that the formwork can be easily dismantled without causing damage to the concrete structure or the formwork itself. Additionally, steel formwork is lightweight, making it easy to handle during removal and reducing the risk of accidents or injuries. In terms of storage, steel formwork has several advantages. Firstly, it can be stacked and stored in a compact manner, saving space on construction sites or in storage facilities. The modular design of steel formwork panels allows for easy stacking and organization, ensuring efficient storage without taking up excessive space. Furthermore, steel formwork is more resistant to damage from weather conditions compared to other materials like wood or plywood. It can withstand exposure to rain, sunlight, and temperature fluctuations without warping, rotting, or deteriorating. This durability makes steel formwork reliable for long-term storage, as it can be reused multiple times without significant degradation. In conclusion, steel formwork is an excellent solution for formwork removal and storage. Its strength and durability allow for easy dismantling and removal, while its modular design and compact storage capabilities make it ideal for efficient storage. With these advantages, steel formwork contributes to increased productivity and cost-effectiveness in construction projects.

- Q: What are the typical safety precautions when working with steel formwork?

- To ensure the safety of workers and prevent accidents, it is important to adhere to various safety measures when working with steel formwork. These measures include: 1. Personal Protective Equipment (PPE): Workers must wear the appropriate PPE, such as hard hats, safety goggles, gloves, and steel-toed boots, to protect themselves from falling objects, flying debris, and foot injuries. 2. Training: Workers should receive proper training on the safe use of steel formwork and be aware of the potential hazards associated with the equipment. They should also be educated on proper lifting techniques and the handling of heavy steel components. 3. Inspection: Before commencing work, a thorough inspection of the steel formwork should be conducted to identify any defects, damage, or weak points. Any faulty or worn-out components must be replaced immediately to prevent accidents or collapses. 4. Secure Anchoring: It is crucial to securely anchor the steel formwork to prevent shifting or collapsing during construction activities. Sufficient bracing and supports should be in place to ensure stability and avoid unexpected movements. 5. Proper Handling and Lifting Techniques: Workers should employ appropriate lifting techniques when handling heavy steel components to prevent strains, back injuries, or accidents. The use of mechanical aids, such as cranes, hoists, or forklifts, should be considered to minimize the risks associated with manual handling. 6. Fall Protection: When working at heights, appropriate fall protection measures, such as guardrails, safety harnesses, or safety nets, should be utilized to prevent falls and injuries. 7. Communication and Signage: Clear communication among workers is vital to avoid accidents. Adequate signage should be displayed to indicate the presence of steel formwork, potential hazards, and restricted areas. 8. Regular Maintenance: Regular maintenance and inspections of the steel formwork should be carried out to ensure its structural integrity. Any identified issues should be promptly addressed to prevent accidents or failures. 9. Emergency Preparedness: Workers should be familiar with the emergency procedures in place, including the location of first aid kits, fire extinguishers, and evacuation routes. Regular drills and training sessions should be conducted to ensure workers are prepared for potential emergencies. By adhering to these safety precautions, the risk of accidents, injuries, and property damage when working with steel formwork can be significantly reduced, thereby creating a safer working environment for all involved.

- Q: What are the different types of safety systems used with steel formwork?

- There are several different types of safety systems that are commonly used with steel formwork to ensure the safety of workers and prevent accidents on construction sites. Some of the most common safety systems used with steel formwork include: 1. Guardrails: Guardrails are typically installed along the edges of the formwork to prevent workers from falling off or slipping. They are usually made of steel or aluminum and are designed to withstand a certain amount of force. 2. Safety harnesses: Safety harnesses are worn by workers and are attached to a secure anchor point to prevent falls. They are typically made of strong, durable materials and are adjustable to fit different body sizes. 3. Toe boards: Toe boards are installed at the bottom of the formwork to prevent tools, materials, or debris from falling off the structure. They are typically made of plywood or steel and are securely attached to the formwork. 4. Safety nets: Safety nets are installed beneath the formwork to catch falling objects or workers in case of an accident. They are made of strong, flexible materials and are capable of absorbing the impact of a fall. 5. Ladders and stairs: Ladders and stairs are used to provide safe access to and from the formwork. They are typically made of steel or aluminum and are designed to be sturdy and stable. 6. Warning signs and barricades: Warning signs and barricades are used to alert workers and visitors to potential hazards and restricted areas. They are typically made of durable materials and are brightly colored for high visibility. 7. Personal protective equipment (PPE): Personal protective equipment, such as hard hats, safety glasses, and steel-toed boots, is an essential safety system used with steel formwork. PPE is designed to protect workers from head injuries, eye injuries, and foot injuries. It is important to note that the specific safety systems used with steel formwork may vary depending on the specific project requirements and regulations. It is crucial for construction companies and workers to follow all safety guidelines and regulations to ensure a safe working environment.

- Q: What are the common design considerations for steel formwork in hot climates?

- When designing steel formwork for utilization in hot climates, there are various common factors that must be considered. 1. Thermal Expansion: Steel possesses a high coefficient of thermal expansion, implying that it expands and contracts with temperature fluctuations. In hot climates, where temperatures can reach exceptionally high levels, it is crucial to account for this expansion in the formwork's design. Sufficient provision for expansion joints and allowances should be made to accommodate the thermal movement of the steel. 2. Heat Resistance: Steel formwork should be designed to endure elevated temperatures without experiencing significant deformation or loss of strength. This may involve the selection of steel grades with superior heat resistance or the implementation of additional cooling measures to prevent overheating. 3. Corrosion Protection: Hot and humid climates can expedite the corrosion process, necessitating the incorporation of effective corrosion protection measures in the design. This can be achieved through the utilization of corrosion-resistant coatings, such as galvanization or epoxy coatings, or by integrating sacrificial anodes to safeguard the steel against corrosion. 4. Ventilation: Hot climates typically necessitate adequate ventilation to prevent the accumulation of heat and moisture within the formwork. Appropriately designed openings and vents should be included to facilitate air circulation and avert the formation of condensation, which can lead to corrosion and diminish the formwork's lifespan. 5. Insulation: In exceedingly hot climates, insulation can assist in minimizing the transfer of heat to the formwork, thereby reducing the impact of thermal expansion and diminishing the risk of deformation. Insulation materials, such as foam or reflective coatings, can be employed to create a barrier between the steel formwork and the external environment. 6. Durability: The design of steel formwork should account for the long-term durability requirements of the project. This includes the selection of materials and construction methods that exhibit resistance to degradation caused by UV radiation, extreme temperatures, and other environmental factors commonly encountered in hot climates. In summary, the design of steel formwork for use in hot climates necessitates careful consideration of thermal expansion, heat resistance, corrosion protection, ventilation, insulation, and durability. By addressing these factors, the formwork can endure the challenges posed by hot climates and ensure the successful completion of construction projects.

- Q: How does steel formwork affect the overall long-term performance of the structure?

- The overall long-term performance of a structure can be significantly influenced by the use of steel formwork. One of the main advantages of steel formwork is its durability, as steel is a robust and resilient material that can endure heavy loads and extreme weather conditions, thereby ensuring the structure's longevity. The utilization of steel formwork provides a rigid and stable framework for pouring concrete. This, in turn, leads to a more precise and accurate construction process, ultimately resulting in a stronger and higher quality structure. Moreover, steel formwork allows for quicker construction as it can be easily assembled and disassembled, reducing the overall construction time. Additionally, steel formwork offers a smooth and flat surface finish, which is vital for the aesthetic appeal of the structure. The smooth surface reduces the need for additional finishing work, saving both time and money. Furthermore, the use of steel formwork guarantees proper support and reinforcement for the concrete, preventing issues such as cracking, sagging, or deformation over time. Another advantage of steel formwork is its reusability. Unlike traditional wooden formwork, steel formwork can be used multiple times, resulting in cost savings and a reduced environmental impact. The durability and strength of steel formwork enable it to endure the wear and tear of multiple uses, making it a more sustainable option. To summarize, steel formwork has a positive impact on the overall long-term performance of a structure by providing durability, strength, accuracy, and reusability. It ensures a construction process of high quality, resulting in a robust and aesthetically pleasing structure that can withstand the test of time.

- Q: What are the different types of safety precautions required when working with steel formwork?

- When working with steel formwork, there are several safety precautions that need to be followed to ensure the safety of workers. Some of the different types of safety precautions required include: 1. Personal Protective Equipment (PPE): Workers should wear appropriate PPE such as safety helmets, safety glasses, gloves, and safety shoes to protect themselves from potential hazards like falling objects or sharp edges. 2. Fall Protection: Fall protection measures like guardrails or safety harnesses should be installed to prevent workers from falling off elevated platforms or structures. 3. Adequate Training: Workers should receive proper training on the safe handling and use of steel formwork equipment. They should be educated about the potential risks associated with the work and how to mitigate them. 4. Proper Installation and Maintenance: Steel formwork should be correctly installed and regularly inspected for any defects or damage. Any faulty or damaged parts should be repaired or replaced to ensure the structural integrity of the formwork. 5. Secure Storage: When not in use, steel formwork should be stored in a safe and designated area to prevent accidents caused by improper storage or falling objects. 6. Communication and Signage: Clear communication and signage should be in place to inform workers about potential hazards, safety procedures, and emergency exits. 7. Proper Lifting Techniques: Workers should be trained on proper lifting techniques to avoid strains or injuries when handling heavy steel formwork components. 8. Fire Safety: Fire extinguishers and other fire safety equipment should be readily available on-site to address any fire emergencies. 9. Electrical Safety: If working near electrical equipment or power lines, workers should be trained on electrical safety procedures and take necessary precautions to prevent electrical hazards. 10. Regular Safety Meetings and Inspections: Regular safety meetings should be conducted to address any safety concerns or issues. Additionally, inspections should be carried out periodically to identify and rectify any potential safety hazards. By adhering to these safety precautions, workers can minimize the risk of accidents and injuries while working with steel formwork, ensuring a safe working environment.

- Q: How does steel formwork contribute to the overall acoustics of the structure?

- Steel formwork does not directly contribute to the overall acoustics of a structure. Acoustics in a building are primarily determined by the materials used for walls, floors, and ceilings, as well as the design and layout of the space. However, steel formwork can indirectly impact the acoustics by providing a rigid and stable framework for concrete construction. Steel formwork is often used in the construction industry to create temporary molds or frameworks for pouring concrete. This formwork system ensures that the concrete has the desired shape and structure when it hardens. While steel formwork itself does not have any specific acoustic properties, it can help create a solid and soundproof structure by providing a precise and consistent framework for the concrete. When constructing a building, it is essential to minimize any gaps or inconsistencies in the concrete to prevent sound leakage and ensure good acoustic performance. Steel formwork, being rigid and strong, helps maintain the desired shape of the structure, resulting in a more accurate and uniform concrete finish. This, in turn, can contribute to better acoustics by reducing the potential for sound transmission through the structure. Moreover, steel formwork can also play a role in the overall durability and stability of the building, which indirectly impacts the acoustics. By providing a sturdy framework, steel formwork helps create a robust structure that is less prone to vibrations and structural movement. This stability can help reduce the transmission of unwanted noise and vibrations within the building, resulting in improved acoustic performance. In summary, while steel formwork does not directly contribute to the acoustics of a structure, it indirectly influences it by providing a precise and stable framework for pouring concrete. This helps create a more uniform and soundproof structure, reducing sound transmission and improving overall acoustics.

- Q: How does steel formwork compare to other formwork materials in terms of cost?

- Compared to timber or plywood, steel formwork generally carries a higher price tag. However, when considering the overall expenses of a construction project, steel formwork has the potential to save costs in the long run. Although the initial cost of steel formwork may be greater, it boasts exceptional durability and can be reused multiple times without compromising its structural integrity. This reusability feature diminishes the need for constant replacement or repair, ultimately reducing the overall expenses for formwork materials in the long term. Furthermore, steel formwork provides unparalleled strength, stability, and precision in shaping concrete structures, resulting in a superior final product. This, in turn, can lead to reduced labor expenses and shorter construction durations, effectively counterbalancing the initial investment in steel formwork. Moreover, steel formwork offers heightened safety due to its fire-resistant properties and ability to withstand extreme weather conditions. This lowers the chances of accidents or damage during the construction process, which can potentially result in savings on insurance costs. Although steel formwork may initially be more costly than alternative materials, it offers a multitude of advantages that can lead to cost savings throughout the entirety of the construction process.

- Q: What are the considerations when designing steel formwork for architectural canopies?

- When designing steel formwork for architectural canopies, several important considerations need to be taken into account. These include: 1. Structural Integrity: The formwork must be designed to withstand the loads imposed by the canopy, including dead loads (self-weight), live loads (such as wind and snow), and any other potential loads such as hanging fixtures. The steel formwork should be structurally robust to ensure the stability and safety of the canopy. 2. Aesthetic Appeal: Architectural canopies are often designed to enhance the overall visual appeal of a building. Therefore, the steel formwork should be designed in a way that complements the desired aesthetics of the canopy. This could involve incorporating decorative elements, such as patterns or textures, into the formwork design. 3. Ease of Installation: The formwork should be designed for easy and efficient installation. This could involve using modular components that can be assembled quickly and easily on-site. It is also important to consider the weight and size of the formwork elements to ensure they can be handled and installed safely. 4. Durability and Maintenance: Steel formwork should be designed to withstand the environmental conditions to which it will be exposed. This may include protection against corrosion, UV radiation, and other potential causes of deterioration. Additionally, the formwork should be designed for easy maintenance and repair, if necessary. 5. Functionality: The formwork must be designed to accommodate any specific functional requirements of the canopy. This could include providing space for utility connections, such as lighting or drainage systems, or incorporating features such as rainwater collection systems. 6. Cost-effectiveness: The design of the steel formwork should consider the overall cost of the canopy project. This includes not only the initial cost of the formwork itself but also factors such as ease of transportation and installation, as well as long-term maintenance costs. Overall, the design of steel formwork for architectural canopies requires a careful balance between structural integrity, aesthetics, functionality, and cost-effectiveness. By considering these considerations, architects and engineers can ensure the successful implementation of canopies that are both visually appealing and structurally sound.

- Q: What are the different types of connections used in steel formwork?

- There are several types of connections used in steel formwork, including bolted connections, welded connections, and clamped connections. Bolted connections involve using bolts and nuts to secure the formwork together, ensuring a strong and secure connection. Welded connections involve welding the steel plates or components together, creating a permanent and durable connection. Clamped connections use clamps to hold the formwork in place, providing a quick and adjustable connection method. Each type of connection has its advantages and is chosen based on the specific requirements of the project.

Send your message to us

Protection Platform for Formwork and Scaffolding systems

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords