Mild Q195/215 CNBM Steel Billets Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

| GRADE | SIZE | APPLICATION |

Q195/ Q215 | 100mm*100mm*6m | STEEL STRIP/STRUCTURE STEEL |

| 120mm*120mm*6m | ||

| 130mm*130mm*6m/12m | ||

| 150mm*150mm*6m/12m |

Chemical Compositon

Q195/ 215 | C (%) | Si (%) | Mn (%) | P(%) | S(%) |

| 0.06-0.12 | 0.15-0.30 | 0.35-0.50 | 0.045% Max | 0.045Max |

Company Information:

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

Packing & Delivery

1. Packaging: seaworthy package or as required

2. Delivery: 35-45 days or based on quantity

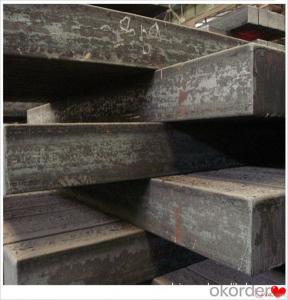

Products Show

Workshop

FAQ:

1.Your advantages?

Professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent

customer solution proposale

2. Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3. Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department

of these factories. Also CNBM is the holding company of many factories.

4. Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5. Trading Terms?

EXW, FOB, CIF, FFR, CNF

6. After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business

partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: What are the different forming processes for special steel?

- There are several forming processes for special steel, including hot forming, cold forming, and powder metallurgy. Hot forming involves heating the steel to a high temperature and then shaping it through processes like forging or rolling. Cold forming, on the other hand, involves shaping the steel at room temperature using processes like bending or extrusion. Powder metallurgy involves compacting metal powders and then sintering them to create a solid piece. These forming processes allow for the production of special steel with unique properties and shapes to meet various industrial needs.

- Q: What are the different methods of surface texturing for special steel?

- Some of the different methods of surface texturing for special steel include shot blasting, etching, electrochemical etching, laser texturing, and milling. These methods are used to create various patterns, textures, or finishes on the surface of the steel, which can enhance its appearance, improve its performance, or provide better adhesion for coatings.

- Q: How does bearing steel resist fatigue?

- Bearing steel resists fatigue due to its high strength, durability, and resistance to deformation. It has a carefully controlled chemical composition and heat treatment process that enhances its mechanical properties, such as hardness and toughness. This allows bearing steel to withstand repeated cycles of stress and loading without experiencing significant fatigue or failure. Additionally, its microstructure, including fine grain size and uniform distribution of carbides, helps to distribute stress evenly and prevent the formation of cracks or weak points that could lead to fatigue failure.

- Q: How is mold steel used in injection molding?

- Mold steel is used in injection molding to create the molds or tooling that are used to produce plastic parts. The steel is used to form the cavity or core of the mold, which determines the shape of the final product. Mold steel is chosen for its high strength, durability, and heat resistance to withstand the high pressures and temperatures involved in the injection molding process.

- Q: How does special steel perform in terms of wear resistance?

- Special steel is known for its exceptional wear resistance, making it highly durable and long-lasting even under harsh conditions. It exhibits superior resistance to abrasion, erosion, and impact, allowing it to withstand heavy usage and minimize wear and tear. This characteristic makes special steel an excellent choice for applications where wear resistance is crucial, such as in the manufacturing of tools, machinery, and automotive components.

- Q: How does special steel contribute to the automotive aftermarket?

- The automotive aftermarket greatly benefits from the inclusion of special steel, as it aids in the advancement and enhancement of various automotive components. This top-notch steel is engineered specifically to possess remarkable strength, endurance, and resistance against wear and tear. One of the primary manners in which special steel contributes to the automotive aftermarket is through the production of performance parts. These parts are crafted to enhance the efficiency and performance of vehicles, catering to the desires and preferences of car enthusiasts. For instance, special steel is utilized in the production of exhaust systems, turbochargers, and intake manifolds, enabling an increase in horsepower and torque, as well as improved fuel efficiency. Furthermore, the production of suspension components, such as coil springs and sway bars, benefits from the usage of special steel. These components provide superior handling and stability, elevating the driving experience and ensuring the safety of both the vehicle and its occupants. Moreover, special steel is essential in the manufacturing of braking systems, encompassing rotors and brake calipers. These components are essential in achieving effective braking and maintaining control of the vehicle. By incorporating special steel, aftermarket brake systems can offer enhanced stopping power, reduced fade, and increased resistance to high temperatures. Additionally, special steel finds application in the production of engine components, including crankshafts, connecting rods, and valve springs. These components endure extreme forces and temperatures, and the exceptional strength and heat resistance of special steel enable them to withstand such conditions, resulting in improved engine performance and longevity. In conclusion, special steel significantly contributes to the automotive aftermarket by aiding in the development of high-performance parts, suspension components, braking systems, and engine components. Its outstanding strength, endurance, and resistance to wear and tear guarantee improved vehicle performance, efficiency, and overall driving experience.

- Q: Can special steel be used in the food packaging industry?

- Yes, special steel can be used in the food packaging industry. Special steels, such as stainless steel, are often preferred due to their corrosion resistance, durability, and hygienic properties. They can be used to manufacture containers, equipment, and machinery for packaging, ensuring safe and efficient food handling and storage.

- Q: What are the properties of magnetic steel?

- Magnetic steel is characterized by its ability to attract and hold a magnetic field. It is typically a hard and strong material, making it suitable for various applications such as in the production of magnets, electrical transformers, and motors. Magnetic steel also has high permeability, allowing it to efficiently conduct magnetic flux. Additionally, it exhibits good resistance to corrosion, which helps maintain its magnetic properties over time.

- Q: How is special steel used in the production of injection molds?

- Special steel is widely used in the production of injection molds due to its unique properties that make it highly suitable for this application. Injection molds are used in the manufacturing of various plastic and metal products through the injection molding process. One of the key reasons for using special steel in injection molds is its excellent heat resistance. During the injection molding process, the molten material is injected into the mold under high pressure and temperature. Special steel can withstand these high temperatures without warping or losing its shape, ensuring the accuracy and precision of the final product. Additionally, special steel has exceptional hardness and wear resistance. The repeated use of injection molds can subject them to significant wear and tear, which can cause dimensional inaccuracies and affect the quality of the molded products. By using special steel, which is specifically designed to be highly resistant to wear, the lifespan of the injection molds is prolonged, ensuring consistent and high-quality production. Special steel also offers good machinability, allowing for intricate and complex mold designs to be accurately manufactured. This enables the production of molds with precise details and intricate geometries, which is crucial for manufacturing complex plastic or metal parts. Furthermore, special steel provides excellent surface finish to the molded products. The smooth and polished surface of the injection molds made from special steel ensures that the final products have a high-quality finish as well. In summary, special steel is extensively used in the production of injection molds due to its exceptional heat resistance, hardness, wear resistance, machinability, and surface finish. These properties make it an ideal material for ensuring accurate and precise manufacturing of plastic and metal products through the injection molding process.

- Q: How does special steel perform in terms of wear resistance in abrasive environments?

- Special steel is known for its exceptional wear resistance in abrasive environments. The unique composition and heat treatment processes used in the production of special steel result in a higher hardness level compared to standard steels. This increased hardness makes special steel highly resistant to wear caused by abrasive particles or surfaces. In abrasive environments where friction and contact with hard materials are prevalent, special steel exhibits excellent performance. It can withstand the erosive effects of abrasive particles, such as sand, rocks, or metal fragments, without significant wear or damage. This durability makes special steel an ideal choice for various applications, including mining equipment, cutting tools, industrial machinery, and automotive components. Moreover, the wear resistance of special steel is not only limited to its surface but also extends throughout its structure. This means that even if the surface of the steel is scratched or abraded, the underlying material remains highly resistant to wear. This characteristic ensures a prolonged lifespan of components made from special steel, reducing maintenance costs and downtime. Furthermore, special steel can maintain its wear resistance even under high temperatures. This property is particularly advantageous in abrasive environments where friction-induced heat can accelerate wear. The ability of special steel to retain its hardness and wear resistance at elevated temperatures ensures its effectiveness in demanding applications like high-speed machining or hot forging. Overall, special steel outperforms standard steels in terms of wear resistance in abrasive environments. Its superior hardness, structural integrity, and temperature resistance make it an excellent choice for applications where durability and longevity are essential.

Send your message to us

Mild Q195/215 CNBM Steel Billets Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords