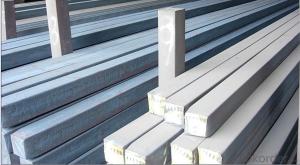

Prime Q275 140mm Square Alloy Steel Billet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Prime Q275 140mm Square Alloy Steel Billet

Description of Prime Q275 140mm Square Alloy Steel Billet

1. Prepainted steel coil is coated with organic layer, which provides higher anti-corrosion property and a longer lifespan than that of galvanized or galvalume steel sheets.

2. The base metals for prepainted steel coil consist of cold rolled, HDGI Steel, electro-galvanized and hot-dip alu-zinc coated steel. The finish coats of prepainted steel coil can be classified into groups as follows: polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc.

3. The production process has evolved from one-coating-and-one-baking to double-coating-and-double-baking, and even three-coating-and-three-baking.

4. The color of the prepainted steel coil has a very wide selection, like orange, cream-colored, dark sky blue, sea blue, bright red, brick red, ivory white, porcelain blue, etc.

5. The prepainted steel coils can also be classified into groups by their surface textures, namely regular prepainted sheets, embossed sheets and printed sheets.

Main Feature of Prime Q275 140mm Square Alloy Steel Billet

They were one of several reasons for the wind to be taken out of the sails of the recent oil price momentum. Kuwait’s oil minister said that his country would only commit to a production freeze if all major producers are involved, including Iran. We also had Goldman telling us that oil markets will not rebalance at $40/bbl as it throws a lifeline to cash-strapped US producers.

If it is talk of a production freeze that is behind the rally it shows how low expectations have fallen. It is in the nature of oil people to talk the market up. Any bullish crumb is given exaggerated significance and any port in a storm will do. It is all but fact that the oil market will be tighter in the second half of this year when seasonal demand shoots up and US production continues to decline. It was the same picture last year. If OPEC and key non-OPEC production is frozen that will ensure the daily surplus will fall, but in all likelihood there will still be a surplus and there is an enormous global stockbuild to burn off.

Applications of Prime Q275 140mm Square Alloy Steel Billet

A. Corrugated design makes it excellent waterproof performance

B. Materials as prepainted steel sheets, galvanized steel sheets, galvalume (Al-Zn coated sheets) are available to make corrugated sheet.

C.Those material are durable, anti-corrosion in bad weather for 20-30 years based on it's Zinc(Galvanized) coating or AZ (Galvalume) coating.

D. Different shape of the sheet make it suitable for any style of buildings.

E.Easy to install, no need special tools to fix the sheet.

F.Light weight due to high strength to weight ratio of steel. Light weight means easier handling lower shipping costs, easier installation

G. Different color is availbe base on the RAL Standard make your building more beautiful.

H. We will provide the best solutions if you don't have a exact idea of the specification you want for the steel sheet based on your weather conditions, engineering structure, construction budget and so on.

Specifications of Prime Q275 140mm Square Alloy Steel Billet

Product | Billet |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.6-3.0mm |

Width | 500-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | Z30-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 1-25MT |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Prime Q275 140mm Square Alloy Steel Billet

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

- Q: What are the common defects in steel billets during hot rolling?

- Certain defects may be experienced by steel billets during hot rolling, which could potentially impact the quality of the final product. Some commonly encountered defects include: 1. Longitudinal surface cracks: These cracks appear on the surface of the billet and may occur due to inadequate cooling, high rolling temperatures, or inferior steel quality. Surface cracks can compromise the structural integrity and performance of the product. 2. Internal cracks: These cracks are found within the billet, away from the surface. They can be caused by insufficient billet heating, uneven temperature distribution, or improper rolling parameters. Internal cracks may lead to material failure or inconsistencies in the final product's dimensions. 3. Surface defects: These defects encompass scales, pits, or scars on the surface of the billet. They are often a consequence of subpar billet preparation, inadequate scale removal, or improper rolling techniques. Surface defects can impact the appearance and surface quality of the final product. 4. Lamination: Lamination defects manifest when there are layers or separations within the billet. They can be caused by impurities in the steel, improper billet preparation, or inadequate rolling parameters. Laminations can result in diminished mechanical properties and compromised structural integrity of the final product. 5. Warping: Warping defects occur when the billet experiences uneven cooling or excessive rolling tensions. This can cause distortion or bending of the billet, leading to inconsistencies in the final product's dimensions. 6. Inclusions: Inclusions refer to non-metallic particles or impurities that become trapped within the steel during the billet formation process. They can lead to reduced mechanical properties, surface defects, or material failure in the final product. To mitigate these defects, it is crucial to exercise proper control over rolling parameters, billet preparation, and cooling processes. Regular inspections and the implementation of quality control measures should be employed to detect and address any defects that may arise during hot rolling.

- Q: What is the typical tensile strength of a steel billet?

- The typical tensile strength of a steel billet can vary depending on factors such as the specific grade of steel and the manufacturing process. However, on average, steel billets typically have a tensile strength ranging from 400 to 600 megapascals (MPa).

- Q: What are the main factors that affect the international trade of steel billets?

- There are several main factors that affect the international trade of steel billets. 1. Economic factors: The state of the global economy plays a crucial role in determining the demand and supply of steel billets. Economic growth and stability in major importing and exporting countries impact the overall demand for steel products, including billets. A strong economy usually leads to increased construction and infrastructure projects, which in turn boosts the demand for steel billets. 2. Government policies and regulations: Trade policies, import/export regulations, and tariffs imposed by governments significantly impact the international trade of steel billets. Governments can impose trade barriers, such as tariffs and quotas, to protect domestic steel industries or address national security concerns. These policies can directly affect the competitiveness and cost of steel billets in the international market. 3. Currency exchange rates: Exchange rates between currencies can influence the competitiveness of steel billets in international markets. If the currency of a steel billet exporting country strengthens against the currency of the importing country, it becomes more expensive for the importing country to purchase steel billets. This can impact the demand and prices of steel billets in international trade. 4. Technological advancements: Technological advancements in steel production and manufacturing processes can affect the international trade of steel billets. Improvements in production efficiency, quality control, and the development of new steel grades can give certain countries a competitive advantage in the global market. Innovative manufacturing techniques can lead to cost reductions and improved product quality, making steel billets more attractive to international buyers. 5. Environmental and sustainability considerations: Increasingly, environmental regulations and sustainability concerns are becoming important factors in international trade. Countries with stricter environmental regulations may require steel billet exporters to meet certain standards or obtain certifications, which can affect their competitiveness in the international market. Additionally, the demand for sustainable and low-carbon steel products is growing, which can influence the trade of steel billets. 6. Political stability and geopolitical factors: Political stability and geopolitical tensions can also impact the international trade of steel billets. Political instability, conflicts, or trade disputes between countries can disrupt supply chains, affect market access, and create uncertainties in the international trade of steel billets. These factors can lead to disruptions in trade flows and impact the prices and availability of steel billets in the global market. Overall, the international trade of steel billets is influenced by a combination of economic, regulatory, technological, environmental, and geopolitical factors. Understanding and monitoring these factors is crucial for stakeholders in the steel industry to navigate the complexities of the global market and make informed decisions.

- Q: Are steel billets affected by extreme temperatures?

- Yes, steel billets are affected by extreme temperatures. When exposed to high temperatures, steel billets can expand and deform. This is due to the thermal expansion property of steel, where it expands in size as it is heated. On the other hand, when subjected to extremely low temperatures, steel billets can contract and become more brittle. This is because the cold temperature reduces the ductility of steel, making it more prone to fracture. Therefore, it is crucial to consider the effect of extreme temperatures on steel billets when designing, handling, and storing them to prevent any unwanted deformation or failure.

- Q: What are the common surface treatments for steel billets?

- Steel billets can undergo several surface treatments to improve performance and protect against corrosion. Common treatments include: 1. Hot-dip galvanizing: Immersing billets in molten zinc creates a protective coating, offering excellent corrosion resistance for outdoor applications. 2. Electroplating: Passing an electric current through a metal ion solution deposits metals like nickel, chromium, or zinc onto billet surfaces, providing desired properties and appearance. 3. Powder coating: Spraying dry powder onto billet surfaces and heating it forms a durable, chemical-resistant coating. This method offers various color options and UV radiation protection. 4. Phosphating: Applying a phosphate coating improves corrosion resistance and promotes paint adhesion, suitable for subsequent painting or powder coating. 5. Blackening: Applying a chemical solution creates a black oxide layer, enhancing appearance and providing mild corrosion resistance for decorative purposes. 6. Passivation: Treating billets with an acid solution removes contaminants and creates a passive oxide layer, improving corrosion resistance, especially for stainless steel billets. These treatments are widely used in industries to enhance billet properties and lifespan. The choice depends on specific requirements, including application, appearance, and environmental conditions.

- Q: How do steel billets contribute to the manufacturing of HVAC systems?

- Steel billets are used in the manufacturing of HVAC systems as they provide the raw material required for fabricating various components such as ductwork, heating coils, and air conditioning units. Billets are melted down and then shaped into the desired form, allowing manufacturers to create durable and sturdy components that can withstand the demanding conditions of HVAC systems. Additionally, steel billets offer excellent thermal conductivity, allowing for efficient heat transfer within the system, ultimately contributing to the overall performance and energy efficiency of HVAC systems.

- Q: Can steel billets be used in the aerospace industry?

- Yes, steel billets can be used in the aerospace industry. Steel billets are a semi-finished product that can be further processed into various components and structures required for aerospace applications. Steel is known for its high strength, durability, and heat resistance, which are crucial properties for aerospace materials. Steel billets can be used to manufacture various aerospace components such as engine parts, landing gear, structural frames, and fasteners. Additionally, steel's availability and cost-effectiveness make it an attractive choice for certain aerospace applications. However, it is important to note that the specific requirements and standards of the aerospace industry must be met when using steel billets to ensure the highest level of safety and reliability.

- Q: How are steel billets used in the production of industrial furnaces?

- Steel billets are an essential component in the production of industrial furnaces. These billets, which are semi-finished steel products, serve as the raw material for manufacturing various furnace components. To begin with, steel billets are used to fabricate the furnace shell or casing, which provides the structural integrity and containment for the furnace. The billets are shaped and welded together to form a sturdy and durable outer shell that can withstand the high temperatures and harsh conditions within the furnace. Moreover, steel billets are used to construct the furnace doors and access panels. These components need to be strong and resistant to deformation and warping caused by the intense heat generated inside the furnace. By using steel billets, manufacturers can ensure that the doors and access panels can be opened and closed easily, while maintaining their structural integrity over time. Furthermore, steel billets are also utilized in the production of furnace grates and supports. These components are responsible for holding and supporting the materials being heated inside the furnace. By using steel billets, manufacturers can create robust and heat-resistant supports that are capable of withstanding heavy loads and high temperatures for extended periods. In addition, steel billets are often used in the fabrication of heat exchangers within industrial furnaces. Heat exchangers are vital for transferring heat from the combustion chamber to the materials being processed. The use of steel billets ensures that the heat exchangers have excellent thermal conductivity and can withstand the corrosive effects of the furnace environment. Overall, steel billets play a crucial role in the production of industrial furnaces by providing the necessary strength, durability, and heat-resistant properties required for their various components. Without steel billets, it would be challenging to manufacture furnaces capable of withstanding the extreme conditions encountered in industrial processes.

- Q: What industries rely heavily on steel billets?

- Steel billets are an essential raw material for numerous industries, with construction being one of them. The construction industry relies on steel billets to fabricate structural components like beams, columns, and reinforcement bars, which are crucial for constructing buildings, bridges, and infrastructure projects. The strength and durability provided by steel billets are necessary for these construction applications. Another industry heavily dependent on steel billets is the automotive industry. They are used to manufacture different automotive parts, including engine components, chassis, and suspension systems. Steel billets are ideal for producing parts that can endure rigorous conditions and ensure vehicle safety due to their high strength and versatility. The oil and gas industry is also heavily reliant on steel billets for the production of pipelines, drill pipes, and other equipment used in exploration, extraction, and transportation processes. Steel billets are preferred in this industry for their corrosion resistance, high pressure resistance, and ability to withstand extreme temperatures. Furthermore, the machinery and equipment manufacturing industry extensively utilizes steel billets as the primary material for producing a wide range of machinery, including industrial machinery, agricultural equipment, and heavy-duty machinery. Steel billets provide the necessary strength, toughness, and machinability required for these applications. Moreover, the aerospace industry heavily depends on steel billets for manufacturing various aircraft components like landing gear, structural frames, and engine parts. Steel billets are chosen for their high strength-to-weight ratio, heat resistance, and ability to withstand the demanding conditions of aerospace applications. In conclusion, steel billets are indispensable in various industries such as construction, automotive, oil and gas, machinery and equipment manufacturing, and aerospace. Their unique properties ensure the production of strong, durable, and reliable products, making them vital for these industries.

- Q: How do steel billets contribute to the automotive industry?

- The automotive industry heavily relies on steel billets as the primary raw material for manufacturing different automotive components. These components, including engine parts, transmission systems, chassis, suspension systems, and other critical parts, are crucial for ensuring the safety, performance, and durability of vehicles. A significant contribution of steel billets to the automotive industry lies in their exceptional strength and durability. Steel is widely known for its high tensile strength, which enables it to withstand extreme forces and provide structural integrity to automotive components. This strength is particularly crucial in areas such as the frame, where it ensures passenger safety in the event of a collision. Moreover, steel billets offer excellent formability and versatility, allowing manufacturers to create intricate and complex automotive parts with precision. This enables the production of components that meet the specific design requirements of different vehicle models, ensuring optimal performance and functionality. Another advantage of steel billets is their cost-effectiveness. Compared to alternatives like aluminum or carbon fiber, steel is a relatively affordable material. Its widespread availability and production efficiency make it an economical choice for mass production, helping to keep vehicle prices reasonable for consumers. Furthermore, steel billets possess excellent heat resistance and thermal conductivity properties, making them ideal for use in engine components, such as pistons and cylinder heads. They can withstand high temperatures and efficiently transfer heat. Additionally, steel billets contribute to the sustainability of the automotive industry. Steel is highly recyclable, with a recycling rate of around 90%. This allows for the eco-friendly disposal and reuse of steel components, reducing the environmental impact of the automotive manufacturing process. In conclusion, steel billets play a crucial role in the automotive industry by providing the necessary strength, durability, formability, and cost-effectiveness for manufacturing various automotive components. Their versatility and recyclability further contribute to the sustainability of the industry. Without steel billets, the automotive industry would face challenges in producing safe, reliable, and affordable vehicles.

Send your message to us

Prime Q275 140mm Square Alloy Steel Billet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords