Print Prepainted Galvanized Steel Coil Wooden Pattern for Furnitures

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 12 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Print Prepainted Galvanized Steel Coil Wooden Pattern for Furnitures:

With Gi as base metal,after pretreatmet (degrease and chemical treatment) and liquid dope with several Layers of color,then after firing and cooling,finally the plate steel is called pre-painted galvanized steel ( PPGI) .Pre-painted galvanized steel is good capable of decoration ,molding,corrosion resistance

2.Main Features of Print Prepainted Galvanized Steel Coil Wooden Pattern for Furnitures:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

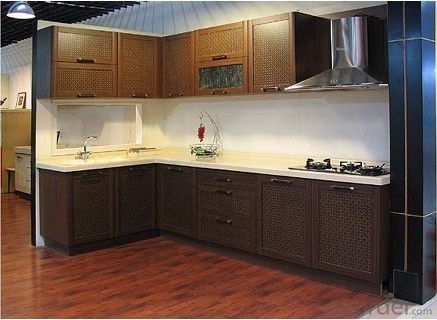

3.Print Prepainted Galvanized Steel Coil Wooden Pattern for Furnitures Images

4.Print Prepainted Galvanized Steel Coil Wooden Pattern for Furnitures Specification

Standard:ASTM, GB,JIS,JIS G3302 ASTM 755 EN10169

Grade: DX51D CGCC CS

Thickness: 0.13mm~3.0mm,

Width: 1250,600-1250mm

Coil weight:3-12 MT

Coil ID:508/610mm

Chemical composition:

C | Si | Mn | Cr | Ni | P | S |

0.150 | 0.476 | 11.231 | 12.50 | 0.900 | 0.039 | 0.010

|

5.FAQ of Print Prepainted Galvanized Steel Coil Wooden Pattern for Furnitures

We have organized several common questions for our clients,may help you sincerely:

1.How do you control your quality

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2.How long we will receive the goods ?

After receiving your deposit or workable lc ,our normal shipment date is 15-20days,and it takes around 28 days to reach your port of destination. But is up to different destination

3. What is your MOQ?

Normally our MOQ is 25mt per size ,but it is up to different size.

- Q: What is the difference between a self-color and painted steel sheet?

- A steel sheet that has not been coated or treated with any additional colors or finishes is referred to as a self-color steel sheet. It maintains the steel surface's natural color and appearance, which is typically a metallic gray or silver. Conversely, a painted steel sheet is one that has been coated with a layer of paint or another protective finish. This coating serves multiple purposes, including enhancing the steel sheet's aesthetic appeal, providing additional protection against rust and corrosion, and increasing its durability. The primary distinction between a self-color and painted steel sheet lies in the presence or absence of a coating. While a self-color sheet preserves the raw and natural appearance of the steel, a painted sheet offers a wide array of color options, enabling customization and harmonization with various design schemes. Furthermore, the existence of a paint or protective coating on a steel sheet provides an extra layer of defense against environmental elements such as moisture, chemicals, and UV rays. This helps prevent the steel from corroding or deteriorating over time, thereby extending its lifespan and ensuring its performance in various applications. To summarize, the main contrast between a self-color and painted steel sheet is the presence or absence of a coating. While a self-color sheet retains the natural appearance of steel, a painted sheet offers added protection, customization options, and aesthetic appeal.

- Q: Do the steel sheets have any sharp edges?

- Yes, steel sheets can have sharp edges. During the manufacturing process, steel sheets are often cut or sheared, which can leave sharp edges. It is important to handle steel sheets with caution and use appropriate protective equipment, such as gloves, when working with them to avoid any injuries from the sharp edges.

- Q: Can the steel sheets withstand extreme temperatures?

- Steel sheets are known for their high durability and strength, making them suitable for various applications. When it comes to extreme temperatures, steel sheets generally have a high melting point and can withstand high temperatures without losing their structural integrity. However, it is important to note that the exact temperature limit depends on the specific type and grade of steel being used. For example, stainless steel sheets have a higher resistance to heat compared to carbon steel sheets. Additionally, factors such as the duration of exposure to extreme temperatures and the presence of other environmental factors may also influence the steel sheets' performance. Therefore, it is crucial to consider these factors and consult with experts or refer to specific product specifications to determine if a particular steel sheet is suitable for a specific extreme temperature application.

- Q: Can steel sheets be used in architectural or decorative applications?

- Yes, steel sheets can definitely be used in architectural or decorative applications. Steel is a versatile and durable material that offers numerous benefits for both structural and aesthetic purposes. In architectural applications, steel sheets can be used for roofing, wall cladding, and structural framing, providing strength, stability, and resistance to harsh weather conditions. Additionally, steel sheets can be fabricated into various shapes, sizes, and finishes, allowing architects and designers to create unique and visually appealing structures. In decorative applications, steel sheets can be used for interior and exterior design elements such as decorative panels, screens, railings, and sculptures. The ability to customize steel sheets with various patterns, textures, and colors makes them a popular choice for enhancing the visual appeal of buildings and spaces. Overall, steel sheets are a versatile material that can be utilized in a wide range of architectural and decorative applications, offering both functionality and aesthetics.

- Q: What is the difference between a perforated and woven steel sheet?

- A perforated steel sheet is a metal sheet that has holes or perforations evenly distributed across its surface. These holes can be of various shapes and sizes, such as round, square, or slotted. Perforated steel sheets are commonly used in applications where airflow, visibility, or drainage is required, such as in architectural design, filtration systems, and acoustic panels. The main advantage of perforated steel sheets is their ability to provide these functionalities while still maintaining structural integrity. On the other hand, a woven steel sheet is a metal sheet that is made by interlacing steel wires together in a specific pattern. This interlacing creates a mesh-like structure, where the wires form a series of intersecting horizontal and vertical lines. Woven steel sheets are commonly used in applications that require strength, durability, and security, such as in fencing, guarding, and industrial filtration systems. The main advantage of woven steel sheets is their ability to provide a high level of strength and security due to the tightly interwoven wires. In summary, the main difference between a perforated and woven steel sheet lies in their respective structures and functionalities. Perforated steel sheets have evenly distributed holes across their surface, providing benefits such as airflow and visibility. Woven steel sheets, on the other hand, are made by interlacing steel wires together to form a mesh-like structure, providing benefits such as strength and security. The choice between the two depends on the specific requirements of the application at hand.

- Q: Are the steel sheets suitable for structural applications?

- Steel sheets are an excellent choice for structural applications, given their outstanding strength and durability. They are highly suitable for constructing buildings, bridges, and other structures that necessitate stability and support. With their remarkable tensile strength and capacity to bear heavy loads, steel sheets offer structural integrity and can endure diverse environmental conditions, such as earthquakes, hurricanes, and extreme temperatures. Moreover, steel sheets are easily fabricated and molded to meet precise design specifications, providing flexibility and versatility in structural applications.

- Q: How do steel sheets resist fire?

- Steel sheets resist fire due to their high melting point and low thermal conductivity. When exposed to high temperatures, steel sheets do not easily deform or collapse, maintaining their structural integrity and preventing the spread of fire. Additionally, steel forms a protective layer of iron oxide when heated, known as a fire-resistant scale, which acts as a barrier against further heat transfer. This combination of properties makes steel sheets highly resistant to fire and ideal for use in construction and other applications where fire protection is crucial.

- Q: How do steel sheets perform in terms of earthquake resistance?

- Steel sheets are highly effective in enhancing earthquake resistance due to their high strength and flexibility. The flexibility of steel enables it to absorb and dissipate seismic energy, reducing the impact on the structure. Additionally, steel sheets can be designed and fabricated to withstand specific seismic loads, making them a preferred choice for earthquake-resistant construction.

- Q: P355NL1 what kind of material is the steel plate?

- P355NL1 is the EU standard cryogenic quality grade steel.Its quality parameter is:Thickness 8-260mm;Tensile strength Rm630-450MPa;Yield strength: 355-295MPa;The elongation after fracture is 21-22%.

- Q: Can steel sheets be used in food processing industries?

- Indeed, steel sheets find applicability in the realm of food processing industries. The utilization of stainless steel sheets is widespread in these industries owing to their myriad advantageous characteristics. Stainless steel, being impervious to corrosion, is of utmost importance in an environment where food is processed, as it effectively prevents contamination and guarantees the safety of the final product. Moreover, steel sheets are easily cleaned and maintained, rendering them the ideal choice for industries that prioritize hygiene. Furthermore, stainless steel exhibits non-reactivity towards food, thereby eliminating the risk of harmful chemical leaching into the processed food. The versatility of steel sheets is evident in their various applications within food processing industries, ranging from countertops, worktables, shelving, to equipment surfaces.

Send your message to us

Print Prepainted Galvanized Steel Coil Wooden Pattern for Furnitures

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 12 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords