Price hot dipped galvanized steel coil SS GRADE550

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50342 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

Standard and Grade :

Hot-dip galvanized steel coils | ||||

ASTM A653M-06a | EN10327:2004/ 10326:2004 | JISG 3302-2010 | AS-NZS 4534-2006 | |

Commercial quality | CS | DX51D+Z | SGCC | G1+Z |

Structure steel | SS GRADE 230 | S220GD+Z | SGC340 | G250+Z |

SS GRADE 255 | S250GD+Z | SGC400 | G330+Z | |

SS GRADE 275 | S280GD+Z | SGC440 | G350+Z | |

SS GRADE 340 | S320GD+Z | SGC490 | G450+Z | |

SS GRADE550 | S350GD+Z | SGC570 | G550+Z | |

S550GD+Z | G550+Z | |||

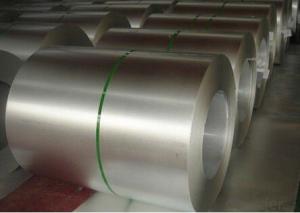

Pictures for stainless steel coil :

FAQ

Q: How do you guarantee the quality of your product?

A: Every process will be checked by responsible QC which insures every product's quality.

Q: How much is your delivery time?

A: Normally within 30 days of receipt of LC original or prepayment, but mostly according to the specific requirements or the quantity

Q: I need sample, could you support?

A: We can supply you with the sample for free, but the delivery charges will be covered by our customers. For avoiding the misunderstanding, it is appreciated if you can provide the International Express Account for Freight Collect. Also you can have a visit to us, welcome to CNBM!

- Q: What are the different methods of punching steel coils?

- There are several methods of punching steel coils, including mechanical punching, hydraulic punching, and laser punching. Mechanical punching involves the use of a mechanical press with a punch and die set to create holes or shapes in the steel coil. Hydraulic punching utilizes hydraulic force to drive a punch through the coil, providing high precision and speed. Laser punching, on the other hand, uses a laser beam to cut or form holes in the steel coil, offering great flexibility and accuracy. Each method has its own advantages and suitability depending on the specific requirements of the application.

- Q: What are the common coil transportation methods?

- The common coil transportation methods include trucking, railway transportation, and shipping.

- Q: What are the common coil surface finish standards?

- The common coil surface finish standards include mill finish, brushed finish, polished finish, and embossed finish.

- Q: I just purchased this Benchmade knife with m390 steel blade and it cost me a fortune but I wanted to know if this new steel is a tool steel. what classifies a tool steel. M390 = 1.9 carbon, 20. chromium, .30 manganese, 1. molybdenum, .60silicon, .60 tugsten, 4. vanadium at 60-62 HRC

- Congratulations you can read a table of steels. Yes M390 is a tool steel. Blades is one application as is the manufacture of injection moulding tools.

- Q: When i was 15 i got caught steeling at Super A yes i know i cant believe it. They didnt call the cops or anything they released me to my aunt they took my name and adress and everythimg they said it wouldnt be on my record. But I'm not so sure. Will it be on my record if they didn't call the cops?i live in california. Is there any way i can check my record?

- Steeling? What's that? Did you take a piece of steel and weld it? I am confused?

- Q: How are steel coils used in the production of railway tracks?

- Steel coils are a crucial component in the production of railway tracks. These coils are typically made of high-quality steel and are used to manufacture the rails that form the foundation of the tracks. The process begins with the steel coils being unwound and fed through a series of machines that shape and form them into the desired rail profile. The steel coils are first passed through a rolling mill, where they are gradually flattened and shaped into long strips of steel. This process is known as hot rolling, as the steel is heated to high temperatures to make it more malleable. The rolling mill applies immense pressure to the steel, gradually transforming it into the desired rail shape. Once the steel coils have been rolled into the required shape, they are then cut into individual rail lengths. These lengths can vary depending on the specifications of the railway track being produced. The rail lengths are then further processed to remove any imperfections and straighten them out. After this initial shaping and processing, the rails are subjected to a series of additional treatments. These treatments may include heat treatment to enhance their strength and durability, as well as various surface treatments to prevent corrosion and wear. Once the rails have undergone all the necessary treatments, they are ready to be installed on the railway track. They are laid out in a carefully planned pattern, with each rail securely fastened to the sleepers or ties. The continuous length of steel provided by the coils ensures a seamless and uniform track, allowing trains to travel smoothly and safely. In summary, steel coils play a vital role in the production of railway tracks. They are used to manufacture the rails that form the foundation of the tracks, ensuring durability, strength, and a smooth surface for trains to run on. The use of high-quality steel coils in this process is essential to ensure the safety and efficiency of railway transportation.

- Q: What are the various surface finishes available for steel coils?

- There are several surface finishes available for steel coils, each with its own unique properties and applications. Some of the most commonly used surface finishes for steel coils include: 1. Hot rolled: This finish is achieved by rolling the steel at high temperatures, which creates a rough, scale-like surface. Hot rolled coils are typically used for structural applications, such as construction materials and industrial machinery. 2. Cold rolled: In contrast to hot rolled coils, cold rolled coils are rolled at room temperature, resulting in a smoother and more refined surface. Cold rolled steel is often used in automotive and appliance manufacturing due to its superior surface finish and dimensional accuracy. 3. Galvanized: Galvanizing is a process that involves coating steel with a layer of zinc to protect it from corrosion. Galvanized steel coils have a shiny, metallic appearance and provide excellent corrosion resistance, making them suitable for outdoor applications, such as roofing, fences, and gutters. 4. Electro-galvanized: Similar to galvanized steel, electro-galvanized coils are also coated with a layer of zinc. However, the coating thickness is typically thinner and achieved through an electroplating process. Electro-galvanized steel coils offer good corrosion resistance and are commonly used in the manufacturing of electrical appliances, automotive parts, and construction components. 5. Pre-painted: Pre-painted steel coils are coated with a layer of paint or polymer film on the surface. This finish provides both protection against corrosion and aesthetic appeal, allowing for a wide range of color options. Pre-painted steel coils are extensively used in the construction industry for applications like roofing, cladding, and wall panels. 6. Stainless steel: While not technically a surface finish, stainless steel coils have their own unique properties that make them suitable for various applications. Stainless steel coils are highly resistant to corrosion, heat, and chemical damage, making them ideal for industries such as food processing, medical equipment, and marine applications. These are just a few examples of the various surface finishes available for steel coils. The choice of finish depends on factors such as the intended application, desired appearance, and level of corrosion resistance required.

- Q: Does SA use its own iron ore to produce steel for construction or do we rely on imports?

- Then people like Bull tell you the country is going down yet Lakshmi and Mark Mobius(read last week's FM) show confidence in SA. Sieman, IBM and CNBC are investing millions in the country. Now who do believe?

- Q: How are steel coils used in the construction of buildings?

- Steel coils are used in the construction of buildings primarily for their strength and durability. These coils are typically formed into beams, columns, and other structural components, providing a sturdy framework. Additionally, steel coils can be shaped into sheets or plates used for roofing, walls, and flooring, offering excellent resistance to weather and fire. Overall, steel coils play a crucial role in ensuring the stability and longevity of buildings.

- Q: How are steel coils used in the manufacturing of crash structures?

- Steel coils are used in the manufacturing of crash structures as they provide high strength and durability, making them ideal for absorbing impact energy and protecting occupants in case of a collision. The coils are typically shaped and formed into specific components of the crash structure, such as side sills or front rails, which are then integrated into the vehicle's frame. This ensures that the vehicle has the necessary rigidity and structural integrity to withstand and mitigate the forces generated during a crash, thereby enhancing the safety of the occupants.

Send your message to us

Price hot dipped galvanized steel coil SS GRADE550

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50342 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords