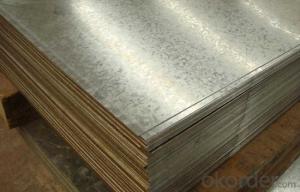

Hot dip galvanized steel coil SGCC

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 20000 Mt m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PRODUCT DESCRIPTION:

Standard | JIS G 3302, ASTM A653, EN10327,10143,GB/T 2518 |

Grade | SPCC, DX51D+Z,CS Type A.B.C |

Zinc Coating | galvanized(GI) |

Zinc Weight | 40~140/m2 |

Thickness | 0.18mm~1.2mm |

Width | 762mm-1,250mm |

Coil weight | 3-20 tons |

Surface processing | Zero Spangle |

Coil Chemical Processing | Skin Pass,chromate,dry,oiled |

packing | waterproof paper and galvanized steel protection cover and steel strip packed Or as you request. |

Application | Construction, hardware, home appliances, interior decoration... |

Advantages | 1. Good experience producing and trading on PPGI/galvanized steel coil /steel sheet. With quality assurance and certification . 2.With technology strength and powerful. 3. Shortest delivery time . 4. authentication service and Sincere Caring Services. 5. We strive to be NO.1 of the same trade |

If you have any need of GI or PPGI Coil,please feel free to contact me.

Alena

- Q: How are steel coils used in the automotive stamping industry?

- Steel coils are used in the automotive stamping industry to provide a continuous supply of flat steel sheets that are then fed into stamping machines. These coils are unrolled, straightened, and then fed through the stamping presses to create various automotive parts, such as body panels, chassis components, and other structural parts. The use of steel coils ensures efficiency, precision, and a consistent quality in the production of automotive parts.

- Q: What are the common coil thicknesses available for steel coils?

- The common coil thicknesses available for steel coils can vary depending on the specific application and industry requirements. However, some of the most common coil thicknesses for steel coils range from 0.5mm to 3mm. These thicknesses are commonly used in various manufacturing processes, including automotive, construction, and appliance industries. For lightweight applications or where flexibility is required, thinner steel coils with thicknesses ranging from 0.5mm to 1.5mm are often used. These thinner coils are suitable for applications such as automotive body panels, roofing, and general sheet metal fabrication. On the other hand, for applications that require higher strength and durability, thicker steel coils with thicknesses ranging from 1.5mm to 3mm are commonly used. These thicker coils are often utilized in heavy-duty construction, structural components, and industrial equipment manufacturing. It is important to note that these are just general ranges, and specific coil thicknesses can vary depending on the specific requirements of a particular project or customer preference. Steel coil thicknesses can be customized to meet specific needs, allowing for greater flexibility in various industries.

- Q: How do steel coils contribute to durability and longevity in products?

- Steel coils contribute to durability and longevity in products mainly due to their strength, stability, and corrosion resistance. Firstly, steel is renowned for its exceptional strength, making it an ideal material for various applications where durability is crucial. Steel coils, which are essentially tightly wound rolls of steel, provide added strength and structural integrity to products. The stability offered by steel coils is another key factor in enhancing the durability of products. The tightly wound structure of the coils ensures they maintain their shape and resist deformation under heavy loads or extreme conditions. This stability is particularly important in industries such as construction and automotive, where products need to withstand rigorous usage over extended periods. Moreover, steel coils possess exceptional corrosion resistance properties, primarily due to the presence of protective coatings. These coatings, such as zinc or other metallic alloys, act as a barrier against moisture and environmental elements that can cause rust and degradation. By preventing corrosion, steel coils help prolong the lifespan of products, making them more durable and reliable. Additionally, steel coils can be customized to meet specific requirements, such as different thicknesses, widths, or surface finishes. This versatility allows manufacturers to tailor the steel coils to their desired application, ensuring optimal performance and longevity in their products. In summary, steel coils contribute to durability and longevity in products through their strength, stability, corrosion resistance, and customization capabilities. By incorporating steel coils into various industries and applications, manufacturers can ensure their products withstand the test of time, ultimately benefiting consumers with longer-lasting and more reliable products.

- Q: What are the key factors affecting the strength of a steel coil?

- The key factors affecting the strength of a steel coil are the quality of the raw material used, the manufacturing process employed, the level of heat treatment, and the presence of any impurities or defects in the steel.

- Q: What are the common coil coating methods?

- The common coil coating methods include roll coating, spray coating, and coil coating with pre-painted metal substrates.

- Q: I have a need to connect various stainless steel tubes and fitting together and was wondering how to do it. I know a TIG welder is an option but have heard rumors that there is a way to solder it in much the same way you affix copper pipe. Perhaps with higher heat and different flux. I need step by step and maybe suppliers of the materials. Thanks in advance and please I do not need the call a plumber answers as I've gotten in the past

- Compression Ferrel connections are the best. for small diameter pipe and tubing. A local hardware shop can supply you with the necessary parts and pieces and can also give you a step by step procedure/self help brochure. This will also allow you to install any valve or t or blank in the piping system. The only tools required will be wrenchs and a tube/piping cutter for this type of installation. Brazing is accomplished by heating the base metal and then the rod. There are different types of brazing rod such as brass, bronze etc.. you will also need a can of flux to coat the rod or you can buy the rod pre-coated. If the seam is flat metal you can use the heat from the brazing tip to make the filler rod follow the direction you want. This also includes vertical such as on an auto body. I would suggest practicing this in a safe area. Always utilize a fire extinguisher, brazing goggles, welding gloves and wear a long sleeve shirt for your protection.

- Q: How do steel coils perform in high-pressure applications?

- Due to their robust and durable nature, steel coils are highly effective in high-pressure scenarios. The exceptional tensile strength of steel enables it to endure immense pressure without any distortion or breakdown. Moreover, steel coils are specifically engineered to retain their shape and structural integrity even under the most extreme pressure, making them ideal for deployment in a wide range of high-pressure applications such as hydraulic systems, pressure vessels, and industrial machinery. Furthermore, the exceptional resistance of steel coils to corrosion and high temperatures further augments their performance in high-pressure environments. These qualities, coupled with their reliability and capacity to withstand high pressure, render steel coils the preferred choice for industries seeking resilient and efficient equipment.

- Q: Hey I just got a mini 14 manufactured in 1980. I also had some .223 Wolf steel cased HP rounds (about 200) that i could shoot throught it, but I was just wondering if its a bad idea to use this steel cased ammo...? Only the casing is steel i believe... and the bullet is copper jacketedthanks for your help

- I have used wolf steel cased ammunition as well when I borrowed my friend's AR-15. It's good ammunition and I personally have not experienced a stovepipe or a jam with the ammunition. A Mini 14 is a great .223 civilian rifle made by Ruger and should not jam with the ammunition. If the polymer coating really is a problem sometimes, just don't use it with knockoff AR-15s or Mini-14s but stick with the major manufacturers.

- Q: I am refinishing a table and on my can of polyurethane, it indicates not to sand with steel wool prior to application. Why is that?

- Steel wool will leave invisible pieces of metal embedded in the finish, no matter how much you try to wipe it off. When you cover it with the polyurethane, it is trapped and turns dark over time, ruining the look of the table. Yeh, so follow the directions exactly for the best finish. Good luck!! : /

- Q: if someone wanted to melt cast steel or iron into small-relatively simple shapes such as rod-tapered rod-or etc... how would you go about melting the steel/iron what would the mold need to be made of?

- Steel is melted in a cupola furnace. you don`t cast rods you cast a large ingot and then while its red hot and still soft it is rolled in between gradually reducing shaped rollers so it gets stretched out and the structure of the metal makes it less likely to snap.

Send your message to us

Hot dip galvanized steel coil SGCC

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 20000 Mt m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords