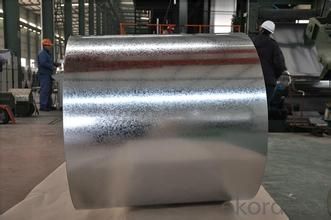

hot-Dip Galvanized/ Aluzinc Steel in SGCC grade in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications.

Specifcation:

1.Mateials:SGCC,DX51D / DX52D /S250,280GD

2.Size:width:600-1250mm(900mm,1215mm,1250mm,1000mm the most common)

thickness:0.15-2.0mm

length:1000-6000mm,as your require

3.Zinc coating :60-180g( as required)

4.Coil id:508mm

5.Coil weight: 3-5MT(as required)

6. Surface:regular/mini/zero spangle, chromated, skin pass, dry etc.

Images:

We can ensure that stable quality standards are maintained, strictly meeting both market requirements and customers’ expectations. Our products enjoy an excellent reputation and have been exported to Europe, South-America, the Middle-East, Southeast-Asia, Africa and Russia etc.. We sincerely hope to establish good and long-term business relationship with your esteemed company.

- Q: Are steel coils used in the aerospace industry?

- Yes, steel coils are used in the aerospace industry for various applications such as manufacturing aircraft components, structural parts, and engine components.

- Q: How are steel coils used in the construction of bridges?

- Steel coils are used in the construction of bridges primarily for their strength and durability. They are shaped and welded into various structural components, such as beams and girders, which provide support and stability to the bridge structure. Steel coils also serve as reinforcement in concrete structures, enhancing their load-bearing capacity. Additionally, steel coils are used for manufacturing bridge decks, guardrails, and other essential elements that contribute to the overall strength and longevity of the bridge.

- Q: Hello people.Me and the life mate have been working on a fantasy book together and we are currently in the process of outlining the cultures. The culture of our antagonists' is a sort of woodland tribal/celtic[ish] deal and they are very nature oriented. Being a detail freak and wanting to have some real world credibility in the story, I am trying to decide how they produce steel. I want steel to be an important part of the culture, but a thing that is in limited supply. I also do not want there to be a large amount of resources committeded to mining or processing iron ore for steel. So does anyone have any real world ideas explaining how the people can produce steel without using underground mining operations, large processing facilities, and without raping the land?All help and ideas are appreciated

- Well, steel is just modified iron, so you're going to have to start with acquiring the iron first. For that, you're most likely going to be using some sort of underground mining somewhere - either they do that themselves, or they purchase the iron elsewhere. Assuming you're not dealing with meteoric iron (which is possible, but pretty uncommon), or iron sands (not likely in a woodland area), then unless you're dealing with a rocky outcropping with iron veins out in the open, I'm pretty sure there needs to be somebody doing some digging. That said, it doesn't need to be a full raping of the land scenario. A couple of minor mines, some small-scale smelting operations, and somebody knowing the secret of making steel, and it could give you small amounts of steel without making an ecological disaster.

- Q: What are the common methods of joining steel coils together?

- Common methods of joining steel coils together include welding, mechanical fastening (such as using bolts or screws), adhesive bonding, and interlocking methods.

- Q: What are the different methods of galvanizing steel coils?

- There are three main methods of galvanizing steel coils: hot-dip galvanizing, electro-galvanizing, and continuous galvanizing. Hot-dip galvanizing involves immersing the steel coil in a bath of molten zinc, providing a thick and durable coating. Electro-galvanizing uses an electrical current to deposit a thin layer of zinc onto the steel surface. Continuous galvanizing is a process where the steel coil is continuously passed through a series of zinc baths, resulting in a uniform coating.

- Q: How are steel coils used in the production of medical equipment?

- Steel coils have various applications in the manufacturing of medical equipment. One way they are commonly used is in the production of surgical instruments. Scalpels, forceps, and clamps, for example, require a cutting edge that is both sharp and long-lasting. Steel coils are ideal for creating these edges as they can be easily shaped, hardened, and sharpened, ensuring precision and durability. Furthermore, medical devices like braces, orthopedic implants, and prosthetics often incorporate steel coils. These devices necessitate materials with exceptional strength and durability to provide support and stability to the body. Steel coils can be molded into different forms and sizes to meet the specific needs of patients, delivering the required support and functionality. Moreover, steel coils find application in the manufacturing of medical equipment such as MRI machines and X-ray systems. These machines rely on robust and dependable components to guarantee accurate imaging and diagnostics. Steel coils are integral to the construction of these machines as they provide stability and structural support, enabling precise and high-quality imaging. To summarize, steel coils are of utmost importance in the production of medical equipment as they offer strength, durability, and versatility. Whether it's surgical instruments, orthopedic devices, or diagnostic machines, steel coils are utilized to create dependable and high-performing medical equipment that ultimately enhances patient care and outcomes.

- Q: Stains tends to leave on the stainless steel microwave oven and its very hard to clean off the stain (brownish stain) please suggest the best way to remove it.

- i am not sure what country you are in but in australia we have this stuff called easy off bam and if you leave it on for half an hour then wipe it off that does the trick. If that option is not available, I know it sounds silly, but try either toothpaste or some lemon juice mixed with bicarbonate of soda. Good Luck i hope that helps you some :)

- Q: Are steel coils susceptible to damage during storage or transportation?

- Yes, steel coils are susceptible to damage during storage or transportation. Factors such as mishandling, improper stacking, exposure to moisture or extreme temperatures, and inadequate packaging can lead to dents, scratches, corrosion, and even deformation of the coils. Adequate precautions and secure packaging are necessary to minimize the risk of damage during storage or transportation.

- Q: How are steel coils used in the production of metal doors and windows?

- Steel coils are used in the production of metal doors and windows as they are the primary raw material. The coils are processed through various manufacturing techniques such as cutting, bending, and shaping to create the frames and panels of the doors and windows. The steel coils provide strength, durability, and structural integrity to the final products, ensuring long-lasting and secure doors and windows.

- Q: I would like to know the process of making steel from the mining of ore to the final product. Can anybody offer some help? Either where to look, or the process itself. I would like to have included the different options with which to make steel. Through scrap metal, or iron ore briquettes etc... Thanks.

- I believe you are asking about two vastly different processes. This is science so, if you want a specific answer, you have to ask specific questions. VERY Basically... 1) Pig iron production works by melting iron and pouring it into molds that produce ingots called pigs. 2) fraction distillation separates different substances (typically starting in liquid form) by controlled heating so, since different substances boil at different temperatures, the vapors can be captured selectively.

Send your message to us

hot-Dip Galvanized/ Aluzinc Steel in SGCC grade in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords