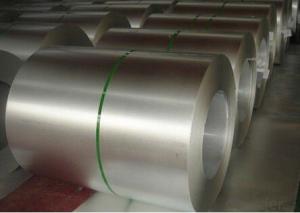

Hot Dipped Galvanized Steel Coils for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Hot Dipped Galvanized steel coil Description:

| Material: | SGCH SGCC SPCC DX51D | application: | construction,automobile,household appliance,etc. | surface: | galvanized,chromated,dry,skin pass... |

| skin pass: | chromated | technique: | cold rolled | spangle: | zero/big/regular/minimum |

| tempering: | bright annealed or full hard | grade: | prime | zinc coating: | 50-220gsm |

| coil weight: | 3-5mt | coil id: | 508mm/610mm |

Main Features of the Hot Dipped Galvanized Steel Coil:

1.FOB:650-1000SUSD/TON

2.size:0.13-0.6mm*750-1250mm*C

3.zinc coating:50-220gsm

4.chromate

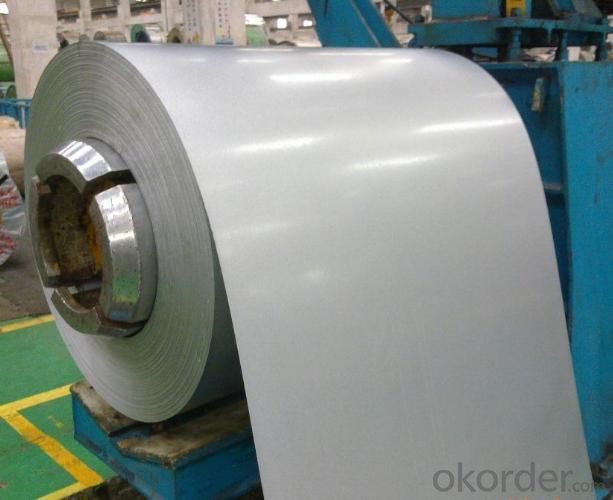

hot dipped galvanized steel coil Specification:

NAME

| PPGI |

GALVANIZED

|

GALVALUME/ALUZINC

|

CERTIFICATE | ISO9001:2008 | ||

GRADE

| CGCC CGCH CGCD1-CGCD3 CGC340-CGC570 GRADE

| SS GRADE33-80 SGCC SGCH SGCD1-SGCD3 SGC340-SGC570 SGCC DX51D | GRADE33-80 SGLCC SGLCD SGLCDD SGLC400-SGLC570 SZACC SZACH SZAC340R |

MODEL NO | 0.16MM-0.8MM*1250MM OR UNDER | (0.127-1.2*1250MM OR UNDER | 0.12MM-2MM*1250MM OR UNDER |

TYPE

|

Steel coil Steel sheets/plates Corrugated steel sheets/plates

| Steel coil Steel sheets/plates Corrugated steel sheets/plates |

Steel coil Steel sheets/plates Corrugated steel sheets/plates

|

TECHNIQUE |

Ccold rolled -galvalume /galvanized -PPGI/PPGL | Cold rolled - galvanized |

Cold rolled -galvalume /Aluzinc

|

SURFACE TREATMENT | Mini/regular/big/zero spangle, Chromate treatment /chromate-free treatment /untreated unoile/oiled, TENSION LEVELLERT SKIN PASS anti-fingerprint/un-anti-fingerprint, Coating,color

| Mini/regular/big/zero spangle, Chromate treatment /chromate-free treatment /untreated unoile/oiled, TENSION LEVELLERT SKIN PASS anti-fingerprint/un-anti-fingerprint, Coating

| |

APPLICATION | Structural use ,roofing, commercial use, household appliance, industry, family

| ||

SPECIAL APPLICATION | Wear resistant steel, high- strength - steel plate | ||

FAQ:

Acceptable payment term and way?

T/T,L/C, T/T + L/C, D/P

Acceptable price term

FOB CNF CIF DDU CPT

Do you accept OA payment terms?

Yes, sure, but it normally depending on the order value

Do you have QC team?

Yeah, sure, our QC team is very important, they will keep the qualitycontrol for our products.

What is the validity of your quotation?

Normally 7 days.

What is your advantage?

24 hour quick response /Customer oriented/ Credit foremost/ Top quality Excellent

What is your acceptable payment term?

TT,LC,OA etc

- Q: How do steel coils contribute to the renewable energy equipment industry?

- Steel coils play a crucial role in the renewable energy equipment industry by being a key component in the manufacturing of various renewable energy technologies. One of the primary applications of steel coils is in the production of wind turbines. The tower, nacelle, and rotor blades of wind turbines all require steel coils for their construction. In the manufacturing of wind turbine towers, steel coils are used to fabricate the structural components that provide stability and support to the turbine. These coils are typically rolled and welded together to form the tower, ensuring its strength and durability to withstand the forces exerted by the wind. Additionally, steel coils are also used to produce the nacelle, which houses the generator and other essential components of the wind turbine. Moreover, steel coils are used in the production of rotor blades for wind turbines. These blades are responsible for capturing the wind and converting it into rotational energy. Steel coils are used to create the internal structure of the blades, providing the necessary strength and rigidity to withstand the aerodynamic forces. The coils are often combined with composite materials to optimize the performance and efficiency of the blades. Apart from wind turbines, steel coils are also used in other renewable energy technologies such as solar panels. In the manufacturing of solar panels, steel coils are used to create the frames and supporting structures that hold the photovoltaic cells in place. These frames ensure the stability and longevity of the solar panels, allowing them to efficiently capture sunlight and convert it into electricity. Overall, steel coils are vital in the renewable energy equipment industry as they provide the necessary strength, durability, and structural support to various renewable energy technologies. By enabling the production of wind turbines, solar panels, and other renewable energy equipment, steel coils contribute to the expansion and development of the renewable energy sector, thereby advancing the global transition towards cleaner and more sustainable sources of energy.

- Q: did bible stated that steel is coming from outer space. i mean meteor rocks that enter our earth sistem contains the minerals iron.

- steel is manufactured from iron ore and coal in furnaces and it is not found in raw state in nature

- Q: How are steel coils used in the production of aerospace components?

- Steel coils are used in the production of aerospace components as they provide the necessary strength and durability required for various applications such as structural parts, fasteners, and landing gear. These coils are typically processed and formed into specific shapes and sizes to meet the design requirements of the aerospace industry.

- Q: What are steel coils used for?

- Steel coils are used in a variety of industries for applications such as manufacturing of automobiles, construction materials, appliances, and packaging materials.

- Q: What are the common coil thickness and width combinations available for steel coils?

- The common coil thickness and width combinations available for steel coils can vary depending on the specific requirements and standards of the industry. However, there are some commonly found combinations that are widely used. In terms of coil thickness, common options range from thin to thick coils. Thin coils typically have a thickness ranging from 0.4mm to 3.0mm, while medium thickness coils can be around 3.0mm to 6.0mm. For thicker coils, the range can be from 6.0mm to 25.0mm or even higher, depending on the specific application. Regarding coil width, it also varies based on the intended usage. Some common options include coils with widths of 600mm, 750mm, 900mm, 1000mm, 1200mm, 1250mm, and 1500mm. However, wider or narrower coils can also be available depending on the specific requirements of the customer or industry. Ultimately, the most suitable coil thickness and width combination will depend on factors such as the intended application, manufacturing processes, transportation limitations, and customer preferences. It is essential to consult with steel coil manufacturers or suppliers to determine the most appropriate options for your specific needs.

- Q: What are the characteristics of hot-rolled steel coils and cold rolled steel coils? What loading and unloading tools should be used? What items should be paid attention to?

- Steel is usually stable in performance. One thing is that the environment should be dry, not rain, because the damp environment is easy to rust. As long as it's in a dry room, it's basically no problem.

- Q: How are steel coils inspected for dimensional accuracy during processing?

- Steel coils are inspected for dimensional accuracy during processing using various methods such as laser measuring systems, ultrasonic thickness gauges, and calipers. These tools are used to measure the width, thickness, and diameter of the coils to ensure they meet the required specifications. Additionally, visual inspections are also conducted to identify any irregularities or defects in the coils.

- Q: What are the safety precautions to be followed while handling steel coils?

- When handling steel coils, there are several safety precautions that should be followed. These include wearing appropriate personal protective equipment, such as gloves and safety glasses, to protect against cuts, abrasions, and eye injuries. It is important to use proper lifting techniques and equipment to prevent strains or back injuries. Steel coils should be securely stacked and stored to prevent them from falling or rolling, and caution should be exercised when moving or transporting them to avoid accidents. Additionally, workers should be trained on the safe handling and storage procedures specific to steel coils to minimize any potential hazards.

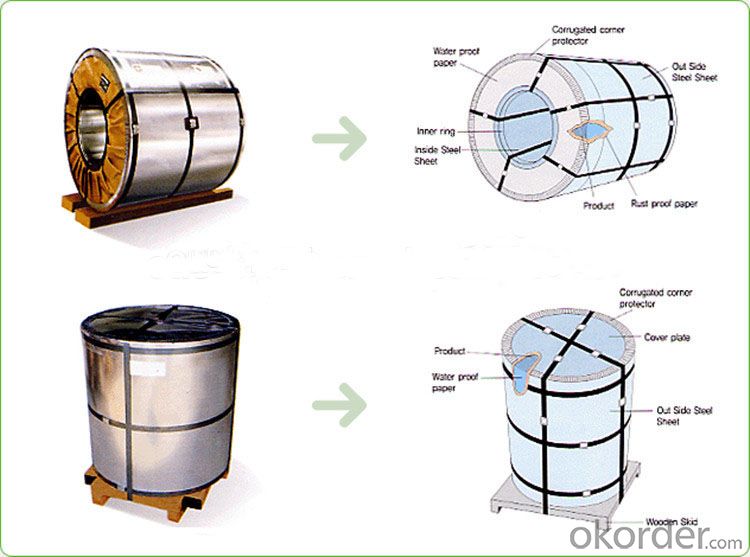

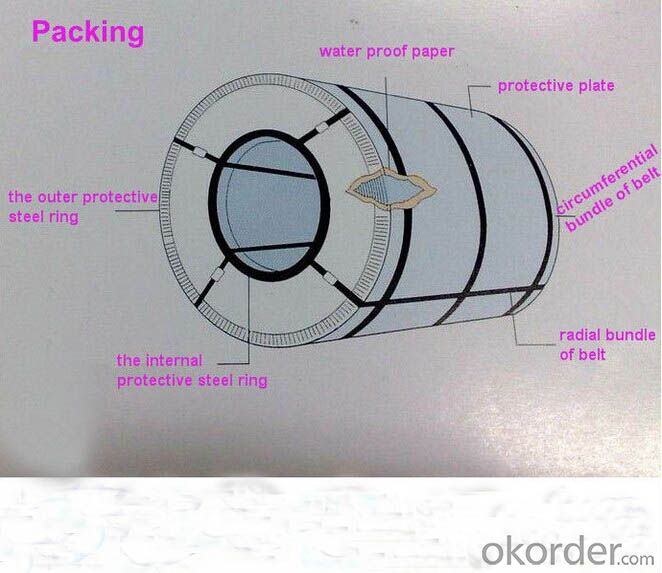

- Q: How are steel coils packaged for shipping?

- Steel coils are typically packaged for shipping by being tightly wound and secured with steel bands or straps. They are then placed on wooden pallets or in steel cradles to ensure stability during transportation. Additionally, protective packaging materials such as plastic or cardboard may be used to prevent damage from moisture, dust, or other external factors.

- Q: any one have an opinion? i've heard steel cut oatmeal is better for you...

- This Site Might Help You. RE: what's the difference between natural rolled oats oatmeal and steel cut oatmeal? any one have an opinion? i've heard steel cut oatmeal is better for you...

Send your message to us

Hot Dipped Galvanized Steel Coils for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords