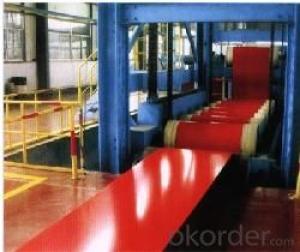

Prepainted Galvanized Steel Coil RAL COLOR

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | AISI,BS,GB,JIS,GB/T 13912-2002 | Grade: | CGCC | Thickness: | 0.15-0.8mm |

| Place of Origin: | Jiangsu China (Mainland) | Brand Name: | Type: | Steel Plate | |

| Technique: | Hot Rolled | Surface Treatment: | Galvanized | Application: | construction industry; automobile making |

| Special Use: | High-strength Steel Plate | Width: | 0.15-0.8mm | Length: | On Request |

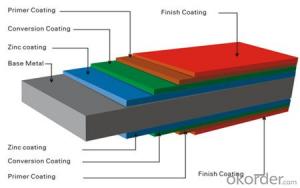

| Color: | On Request | Certificate: | ISO9001TUV | Zinc Coating: | Z60-Z150 or on request |

| Payment: | L/C T/T | Usage: | Buldings | Package: | Standard Export Packing |

| Type of Company: | Manufacturer | MOQ: | 25 Tons | Coil weight: | 3-8MT |

Packaging & Delivery

| Packaging Detail: | Standard Export Packing for the goods pallet packing or according to customer's request |

| Delivery Detail: | within 15-45 days after the receipt of L/C or deposit |

Specifications

Thickness: 0.15-0.8mm

Width: 700-1250mm

Length: On Request

Product Description

Prepainted Galvanised Steel Sheet

Thickness: 0.15-1.5mm

Width: 700-1250mm

Length: As your request

Zinc Coating: 60-150g/ m² or as your request

Advantage:

| HIGH QUALITY |

| LOW PRICE |

| FAST DELIVERY |

Application:

1.Buildings and constructions: roofing, ceilings, gutters, venting lines, indoor decorations, window frames, etc

2.Electrical appliances: computer shells, washing machines, refrigerators, dehumidifiers, video recorders, water heaters, etc.

3. Agricultural equipments: troughs, feeding tools, agricultural driers, irrigation channels, etc.

4. Vehicle parts: back-seat plates of buses and trucks, conveying systems, oil tanks, etc.

- Q: What is the yield strength of steel coils?

- The yield strength of steel coils can vary depending on the specific grade and composition of the steel. However, on average, the yield strength of steel coils typically ranges from 250 to 350 megapascals (MPa).

- Q: How are steel coils affected by global trade policies?

- Steel coils are significantly affected by global trade policies as they are subject to various tariffs, quotas, and trade restrictions imposed by different countries. These policies can impact the cost, availability, and competitiveness of steel coils in the international market. Changes in trade policies can lead to fluctuations in demand and supply, impacting the prices and trade volumes of steel coils.

- Q: Can steel coils be used in the food processing industry?

- Indeed, the food processing industry can utilize steel coils. These coils frequently serve as the foundation for a diverse array of food processing equipment, including conveyor belts, food storage tanks, mixing tanks, and processing machinery. Steel, characterized by its durability and hygienic properties, possesses resistance against corrosion, rendering it appropriate for deployment in food processing environments. Furthermore, steel coils facilitate effortless cleaning and sanitization, guaranteeing the safety and cleanliness of the food processing equipment. In conclusion, owing to their robustness, longevity, and adherence to food safety regulations, steel coils enjoy widespread employment within the food processing industry.

- Q: Correct me if I am wrong, but steel is an alloy between iron and carbon. Does the carbon in the steel stops the iron from rusting or corroding? Also what is the difference between mild steel and stainless steel?

- Mild steel is an alloy. It is the most common form of steel. Mild steel (a so-called carbon steel) is a general term for a range of low carbon (a maximum of about 0.3%) steels that have good strength and can be bent, worked or can be welded into an endless variety of shapes for uses from vehicles (like cars and ships) to building materials. The carbon does not stop the material rusting or corroding. In addition to iron, carbon, and chromium, modern stainless steel may also contain other elements, such as nickel, niobium, molybdenum, and titanium. Nickel, molybdenum, niobium, and chromium enhance the corrosion resistance of stainless steel. It is the addition of a minimum of 12% chromium to the steel that makes it resist rust, or stain 'less' than other types of steel. The chromium in the steel combines with oxygen in the atmosphere to form a thin, invisible layer of chrome-containing oxide, called the passive film. The sizes of chromium atoms and their oxides are similar, so they pack neatly together on the surface of the metal, forming a stable layer only a few atoms thick. If the metal is cut or scratched and the passive film is disrupted, more oxide will quickly form and recover the exposed surface, protecting it from oxidative corrosion.

- Q: How are steel coils inspected for width?

- To ensure compliance with the necessary specifications, various techniques are employed to inspect the width of steel coils. Among these methods, a commonly used one is the utilization of a caliper gauge, also referred to as a micrometer. This gauge makes direct contact with the coil edges to measure its width. The operator places the gauge at multiple points along the width and records the measurements. This approach guarantees precise measurements and facilitates the identification of any inconsistencies or deviations in the desired width. Another technique employed for width inspection is laser measurement. In this method, laser sensors are positioned on both sides of the coil, emitting a laser beam that scans across the width. By detecting the distance between the edges of the coil, the sensors provide accurate width measurements. This non-contact approach is highly efficient, swiftly inspecting the coil's width without causing any physical damage or requiring physical contact. Moreover, advanced systems employ computer vision technology for width inspection. This involves the use of cameras and image processing software to capture images of the coil's edges. The software then analyzes these images and calculates the width based on the detected edges. This method enables rapid inspections and can identify any irregularities in the coil's width. In conclusion, the inspection of steel coil width involves a combination of physical gauges, laser sensors, and computer vision technology. These methods ensure that the coils conform to the required width specifications and play a crucial role in maintaining quality control throughout the steel manufacturing process.

- Q: How are steel coils inspected for quality assurance?

- Quality assurance for steel coils involves a rigorous process that includes various tests and checks to ensure their quality. Initially, a visual inspection is carried out to identify surface defects like scratches, dents, or rust, ensuring the coils are in good condition and free from obvious flaws. Afterward, a dimensional inspection is performed to verify the coils' dimensions and tolerances. This involves measuring their width, thickness, and length to ensure they meet the specified requirements. Any deviations from the standard dimensions are noted and addressed. Moreover, mechanical testing is conducted to assess the strength and durability of the steel coils. Tensile tests are performed to measure their strength and elasticity, while impact tests evaluate their ability to withstand sudden loads or shocks. Furthermore, chemical analysis is undertaken to determine the composition and purity of the steel. Samples are taken from the coils and analyzed in a laboratory to check for impurities or elements that could affect the quality. To comply with industry standards, non-destructive testing methods like ultrasonic testing or magnetic particle inspection may be used. These methods can detect internal defects or irregularities that may not be visible to the naked eye. Additionally, surface treatment inspections, such as galvanization or coating checks, may be performed to ensure the protective layers are applied correctly and meet the necessary specifications. In summary, the quality assurance process for steel coils includes visual, dimensional, mechanical, chemical, and non-destructive testing methods. These thorough inspections guarantee that the steel coils meet the required quality standards and are suitable for their intended applications.

- Q: How do steel coils contribute to the agricultural machinery industry?

- Due to their versatile and durable nature, steel coils play an essential role in the agricultural machinery industry. They are used in various applications and contribute significantly to improving the efficiency and productivity of agricultural machinery. Manufacturing equipment frames and structures is one primary way steel coils contribute to the agricultural machinery industry. These frames provide the necessary strength and stability to withstand the demanding conditions of agricultural operations. Whether it's tractors, harvesters, or tillers, steel coils are utilized to create robust and rigid frames capable of handling heavy loads, vibrations, and impacts. Moreover, steel coils are vital in fabricating components like plow blades, cultivator tines, and seed drills. These components are crucial for soil preparation, seed planting, and crop maintenance. Steel coils provide the necessary strength and resistance to wear and tear, ensuring these components can endure the rigors of agricultural operations and have a prolonged lifespan. Additionally, steel coils are used in manufacturing hydraulic systems and other moving parts in agricultural machinery. These systems are responsible for powering and controlling various functions such as lifting, lowering, and steering. Steel coils provide the necessary strength and flexibility for these systems to function optimally, ensuring smooth and efficient operation of agricultural machinery. Furthermore, the use of steel coils in the construction of agricultural machinery enhances equipment safety and longevity. Steel is renowned for its excellent resistance to corrosion, rust, and extreme weather conditions. By incorporating steel coils in the manufacturing process, equipment remains durable and reliable even in harsh environments, ultimately reducing maintenance costs and improving the overall lifespan of the machinery. In conclusion, the agricultural machinery industry heavily relies on steel coils. Their versatility, strength, and durability are indispensable for manufacturing equipment frames, components, hydraulic systems, and other moving parts. By utilizing steel coils, the agricultural machinery industry can produce robust and efficient equipment capable of withstanding demanding agricultural operations, improving productivity, enhancing safety, and extending the lifespan of the machinery.

- Q: I want to make a chess set out of stainless steel, but I'm not sure what type of mold I need or where I can go to have the steel melted and molded for me. Any ideas? I live in Southern, NJ.

- I'll buy one. You'll have to machine it from blocks... You could invest in a milling machine - they are like drill presses and lathes all together and more... If you hook it up to your computer, you can do a CNC milling, where you can get really creative and finely detailed. Stainless is heavy and hard, so it'll go through your bits, and you should use the super duty bits as well. I have always wanted an SS chess set, I made a board out of leather. It's really super awesome, just need your pieces now. Or make mine from Plutonium, or Tungsten Carbide.

- Q: How are steel coils inspected for quality control purposes?

- Steel coils are inspected for quality control purposes through a series of tests and checks. This may include visual inspection to detect any surface defects, such as scratches or dents. Additionally, measurements and tests are conducted to ensure dimensional accuracy, such as thickness, width, and weight. Non-destructive testing methods, such as magnetic particle testing or ultrasonic testing, are also employed to identify any internal defects, like cracks or voids. These comprehensive inspections help ensure that steel coils meet the required quality standards before they are used in various applications.

- Q: How are steel coils inspected for weldability?

- Steel coils are inspected for weldability through a series of comprehensive tests and examinations. The main objective of this inspection is to assess the quality and suitability of the steel coils for welding processes. Firstly, visual inspection is conducted to identify any visual defects or irregularities on the surface of the coils. This includes checking for surface roughness, cracks, scratches, or any other imperfections that may affect the weldability. Next, destructive testing methods such as tensile testing and impact testing are performed. Tensile testing measures the strength and ductility of the steel, ensuring it meets the required mechanical properties for welding. Impact testing evaluates the steel's resistance to brittle fracture, which is crucial in determining its weldability. Furthermore, non-destructive testing techniques such as ultrasonic testing (UT) and magnetic particle inspection (MPI) are employed to detect internal defects and discontinuities. UT uses high-frequency sound waves to identify any hidden flaws within the steel, while MPI utilizes magnetic particles to identify surface and near-surface defects. Additionally, chemical analysis is carried out to determine the steel's composition and ensure it meets the required specifications for welding. This analysis involves checking the levels of carbon, manganese, sulfur, and other elements that may affect the weldability and overall performance of the steel. Moreover, weldability testing is performed to evaluate the steel's response to welding processes. This involves conducting various welding trials using different techniques and parameters to determine the steel's behavior during welding, such as its susceptibility to cracking, distortion, or other welding-related issues. Overall, the inspection of steel coils for weldability is a multi-faceted process that combines visual, destructive, non-destructive, chemical, and weldability testing methods. By conducting these thorough inspections, manufacturers can ensure that the steel coils meet the required standards and are suitable for welding applications.

Send your message to us

Prepainted Galvanized Steel Coil RAL COLOR

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords