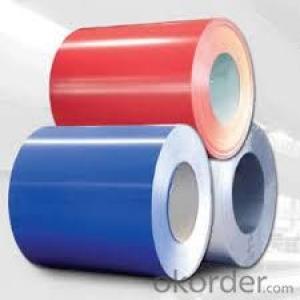

Prepainted galvanized steel sheets/coils SGCC

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1) AVAILABLE DESIGNATION OF (Prepainted galvanized steel coils) printed PPGI coils

Quality Q/BQB 440-2003 JIS G3312-1994 EN 10326-2004 ASTM A653-02a

EN 10327-2004 (BASE PLATE)

(BASE PLATE)

Commercial Steel TDC51D CGCC DX51D+Z/AZ CS Type A/B/C

Forming Steel (TSt01,TSt02,TSt03) CGCD1 FS Type A, Type B

Drawing TDC52D /TDC53D - DX52D+Z/AZ DDS TYPE A/C

Steel DX53D+Z/AZ

Structural TS280GD(TStE28) CGC400 S280D+Z/AZ SS275

Steel TS350GD(TStE34) CGC440 S350D+Z/AZ SS340 Class1

2) OUR SPECIFICATION OF (Prepainted galvanized steel coils) printed PPGI coils

Available Size:

Manufacturer Thickness Width Length of plate Inner diameter of coil

JIANGSU HUIYE STEEL SHEET CO.,LTD 0.2-1.2mm 800/914/1000/1200/1219/1250mm 1000-6000mm 508mm/610mm

Coated Mass OF (Prepainted galvanized steel coils) printed PPGI coils:

Base plate Available Coated Mass(g/m^2)

Galvanized Steel 80, 100, 120, 160, 180

Galvalume Steel 50, 70, 150

Available Painting OF (Prepainted galvanized steel coils) printed PPGI coils:

Category of Painting Item Code

Polyester PE

High-durability polyester HDP

Silicon modified polyesters SMP

Polyvinylidene fluoride PVDF

Easy-Cleaning —

Painting Thickness Top side: 20+5microns;

Bottom side: 5~7microns.

Color System Produce according to RAL Color System or as per buyer’s color sample.

Painting structure Top surface Bottom surface

Primer coating No coating 1/0

Primer coating Primer coating 1/1

Primer coating + Finish coating No coating 2/0

Primer coating + Finish coating Primer coating or single back coating 2/1

Primer coating + Finish coating Primer coating + Finish back coating 2/2

- Q: Why can steel HPB300, steel plate without Q300, steel structure manuscript review, but also continued the Q235, why not improve it?

- HPB's full name is hot rolled round steel (HPB is Hot-rolled Plain Steel Bar) in English, commonly known as wire rod, diameter 6 - 12 rounds of the most common, including HPB235 and HPB300. You haven't met HPB400?. HRB400 and RRB400 are treated steel bars in order to have such high strength. But the general strength, ductility will be reduced, as the saying goes, "tossing" is not resistant to toss about.

- Q: What is the difference between the zinc plated color guide and the profiled steel sheet?

- Because the original plate is very thin, the quality of the anticorrosive coating directly affects the service life of the profiled steel sheet. In order to meet the requirements of processing and rust prevention, the coated steel plate shall be examined in accordance with the relevant provisions. Under normal circumstances, thin steel plate can also be used according to the requirements, after pressing type, and then coated with anti rust paint, or use stainless steel sheet, the original plate.Profiled steel sheet used in industrial plants, housing panels, wall panels, in the absence of general insulation requirements, steel per square meter of about 5~11 kilograms. Insulation requirements, availability of mineral wool board, glass wool, foam and other insulation materials. The profiled steel plate and the concrete are combined into a composite floor board, and the wooden formwork can be omitted, and the utility model can be used as a load-bearing structure. At the same time to strengthen the binding force of steel sheet and concrete, should be pre welding studs in steel plate or pressing two-way stiffener

- Q: Can steel sheets be used for noise barriers?

- Yes, steel sheets can be used for noise barriers. Steel is a durable and robust material that can effectively block or reduce the transmission of sound. It has high density and mass, which helps to absorb and reflect the sound waves, preventing them from passing through the barrier. Steel sheets can be specifically designed and manufactured for noise reduction purposes, with features such as perforations or acoustic insulation materials to enhance their effectiveness. Additionally, steel sheets can be coated or painted to improve their resistance to weather conditions and corrosion. Overall, steel sheets are a viable option for constructing noise barriers, especially in areas with high levels of noise pollution.

- Q: Can steel sheets be used for walkways or platforms?

- Yes, steel sheets can be used for walkways or platforms. Steel is a durable and strong material, making it suitable for supporting heavy loads and providing a safe surface for walking. It is commonly used in industrial settings, construction sites, and other applications where a sturdy and reliable platform is needed.

- Q: 16 what is the hardness of manganese steel plates?

- Manganese steel is a kind of steel with high strength. It is mainly used in harsh working conditions, such as impact, extrusion and material wear. The form of failure is mainly wear and tear, and it is partly broken and deformed.

- Q: Can steel sheets be used for artistic or sculptural projects?

- Yes, steel sheets can be used for artistic or sculptural projects. Steel sheets offer durability, strength, and versatility, making them a popular choice for artists and sculptors. They can be cut, shaped, welded, and manipulated to create various forms and designs, allowing artists to unleash their creativity and bring their visions to life. Additionally, steel sheets can be finished with different coatings or patinas to enhance their aesthetic appeal and protect them from corrosion.

- Q: What is the weight of a typical steel sheet?

- The dimensions and thickness of a steel sheet can cause fluctuations in its weight. Nevertheless, for a rough approximation, a commonly employed steel sheet in construction and manufacturing, measuring 4' x 8', usually weighs approximately 80 to 100 pounds (36 to 45 kilograms). It is crucial to acknowledge that this weight can vary based on the specific steel type and its gauge or thickness.

- Q: Are the steel sheets suitable for architectural applications?

- Indeed, architectural applications can certainly make use of steel sheets. Steel, being a versatile material, presents numerous benefits for architectural purposes. It possesses strength, durability, and the ability to withstand harsh weather conditions, thus making it an excellent choice for various architectural elements like roofing, cladding, and facades. Furthermore, steel sheets provide architects with design flexibility, enabling the creation of unique and innovative structures. Moreover, steel is an environmentally sustainable material due to its recyclability and long lifespan, making it an eco-friendly option for architectural applications. All in all, steel sheets serve as a dependable and versatile choice for architects who desire to incorporate structural integrity, aesthetic allure, and sustainability into their designs.

- Q: Are the steel sheets resistant to vibration or shock?

- Steel sheets are generally resistant to vibration and shock due to their high strength and durability. Steel is known for its ability to withstand external forces like vibrations and shocks, thanks to its rigid nature. This allows steel to effectively absorb and distribute energy caused by vibrations or shocks, preventing any significant damage or deformation. In various industries, such as construction, automotive, and aerospace, steel sheets are commonly used because their resistance to vibrations and shocks is crucial. However, it's important to consider that the exact resistance of steel sheets to vibration or shock depends on factors like thickness, steel quality, and the specific magnitude and frequency of the vibrations or shocks.

- Q: What are the different thickness gauges available for steel sheets?

- There are several thickness gauges available for steel sheets, ranging from standard gauges like 18, 20, 22, 24 gauge to more precise measurements like decimal or millimeter gauge. The choice of gauge depends on the specific application and requirements for the steel sheet.

Send your message to us

Prepainted galvanized steel sheets/coils SGCC

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords