Prepainted galvanized corrugated Plate / Sheet-CGLCC

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

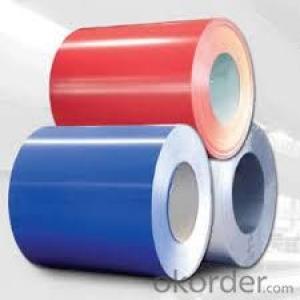

1.material : galvanized steel sheet / prepainted galvanized sheet

2.sheet thickness : normal use 0.3-0.6mm

3.length: any length,according to the transportation,generally less than 12m

4.color: standard color:red,blue,white,grey; pecial color:according to RAL color

Specification:

prepainted corrugated steel plate | |

material | galvanized steel sheet |

prepainted galvanized sheet | |

model No. | types of roof sheets |

sheet thickness | normal use 0.3-0.6mm |

length | any length,according to the transportation,generally less than 12m |

color | standard color:red,blue,white,grey |

special color:according to RAL color | |

characteristic | 1:weather proof |

2:heating insulation | |

3:fireproof | |

4:anti-rust | |

5:sound insulation | |

6:long life span:more than 15 years | |

advantages | 1.low foundation cost |

2.easy construction | |

3.time saving | |

4.labor saving | |

application field | 1:construction:prefabricated house,steel house,mobile house,modular house,villa,bungalow design,portable house/carbin,ready made house,kiosk booths,steel building... |

2:container manufacturing | |

3:household appliances and furniture | |

4:vehicle and vessel manufacturing | |

5:others,like machinery structual parts,maufacturing shells of motors and so on | |

packing | plastic film,pallet or as your request |

Images:

- Q: What is the lifespan of steel coils?

- The lifespan of steel coils can vary depending on various factors such as the quality of the steel, the conditions in which they are stored or used, and the maintenance practices employed. However, with proper care and maintenance, steel coils can last for several decades or even longer.

- Q: What are the different coil packaging materials used for steel coils?

- Different materials are used for packaging steel coils, each with its own unique properties and benefits. Some of the most commonly used materials are as follows: 1. Stretch film is a flexible material that tightly wraps around the coil, providing protection against dust, moisture, and scratches. 2. Steel strapping is a strong and durable option that ensures the coils remain tightly bound during transportation or storage, thanks to its high tensile strength and resistance to breakage. 3. Plastic strapping, on the other hand, is a lightweight and cost-effective alternative to steel strapping. It offers good shock absorption and is resistant to rust and corrosion, making it suitable for smaller or lighter steel coils. 4. Paperboard is an environmentally friendly packaging material that provides a protective layer against dust and minor impacts. It also allows for slight breathability to prevent moisture buildup. 5. Wooden crates are commonly used for large or heavy steel coils, as they offer sturdy support and protection during handling, transportation, or storage. 6. Corrugated cardboard is a versatile and lightweight material suitable for smaller steel coils. It provides cushioning and protection against minor impacts, and it is easily recyclable. The choice of packaging material for steel coils depends on factors such as coil size and weight, transportation requirements, and the desired level of protection. Each material has its own advantages and should be selected based on the specific needs of the steel coil packaging.

- Q: What are the different types of steel coil packaging materials for export?

- Various steel coil packaging materials are commonly utilized for export. These include: 1. Steel Strapping: A frequently employed option, steel strapping ensures robust and reliable packaging for steel coils. It offers excellent protection during transportation and is available in different widths and thicknesses to accommodate varying coil sizes. 2. Stretch Film: This flexible and elastic material is often employed to wrap steel coils securely. By preventing shifting or falling during transit, stretch film ensures tight and dependable packaging. Moreover, its lightweight nature aids in reducing shipping costs. 3. Corrugated Cardboard: Frequently used as an outer packaging material, corrugated cardboard provides additional protection against external impacts and acts as a cushioning material. It is available in various strengths and sizes to suit different coil dimensions. 4. Wooden Crates: Wooden crates are a popular choice for packing larger steel coils. They offer a sturdy and robust packaging solution, effectively safeguarding against impacts, moisture, and other environmental factors. These crates can be customized to fit specific coil sizes and are often employed for heavy-duty or long-distance shipments. 5. Plastic Strapping: Plastic strapping serves as an alternative to steel strapping, particularly for lighter coils. It is lightweight, easy to handle, and resistant to rust and corrosion. Plastic strapping is available in different colors, facilitating easy identification and sorting. 6. VCI (Volatile Corrosion Inhibitor) Packaging: VCI packaging materials are specifically used to protect steel coils from corrosion during export. These materials release a vapor that forms a protective layer on the surface of the coils, preventing rust and corrosion even in high humidity or harsh environments. When selecting the appropriate packaging material for export, it is crucial to consider the size, weight, and specific requirements of the steel coils. Additionally, adherence to international shipping regulations and standards is essential to ensure a safe and efficient transportation process.

- Q: I am making a sword of 1060 carbon steel and would like to know how to heat treat it once it's ready, could anyone help please?

- Heat treating easy, HA! It is the most critical part of bladesmithing. Done wrong and all those hours of work go up in smoke (or a snap of the steel). You'll need a bucket of oil, preferably one that is deep enough to go in point first. If not you'll have to go in edge first, not recommended on a double edged blade, ok for single edge. You'll need to build a charcoal fire long enough for the blade. You will need to blow air under the fire to get it hot enough, the challenge is getting the heat even. You get the fire going and established, put the blade in turning it back and forth (if you keep turning it in the same direction when it heats up you could work a twist in it). When it starts turning red pull it out and touch it with a magnet, if the magnet sticks put it back. Keep heating and repeating until the magnet no longer sticks. Heat a little more, then quench rapidly point first. Don't let the blade lean to one side as warpage will occur. When it cools enough to touch, check with a file. If the doesn't file cut then you've properly hardened the steel and it's ready for temper. Now comes the really hard part. Grind the scale off carefully,preferably with a side grinder with a flap wheel. I've had hard wheel break freshly hardened blades. After cleaning you'll need to put it in an oven (preferred) or use a torch and carefully heat the blade. Watch the temper colors (oven temp 500-550F) or with the torch as the steel turns colors blue to purple for a double edged weapon. Any warpage that occurs needs to be worked out at temping temp.

- Q: How do steel coil manufacturers meet customer specifications?

- Steel coil manufacturers meet customer specifications by carefully analyzing the requirements provided by the customer and utilizing advanced production techniques to ensure precise dimensions, mechanical properties, and surface finishes. They employ strict quality control measures throughout the manufacturing process, including rigorous testing and inspections, to ensure that the coils meet the specified standards. Additionally, manufacturers often collaborate closely with customers to understand their unique needs and provide customized solutions that meet or exceed their expectations.

- Q: What is the process of galvanizing steel coils?

- The process of galvanizing steel coils involves immersing them in a bath of molten zinc to create a protective coating. The coils are first cleaned and then passed through a series of chemical baths to prepare the surface for galvanization. Afterward, they are dipped into the molten zinc, which bonds to the steel to form a corrosion-resistant layer. Once coated, the coils are cooled, inspected, and prepared for shipment or further processing.

- Q: does regular steel rust? or is it all the same.

- There are dozens of types of steels, some stainless and some not. They differ a lot in their chemical composition and in how they're made (especially heat treating methods). They all vary in their strength, working properties and corrosion resistance. Regular steel (technically carbon steel--mostly iron, with a little bit of carbon) rusts quite badly if unprotected and in the right environmental conditions i.e. humidity/moisture. The iron in regular steel reacts with oxygen to form iron oxide--the orange/red stuff we call rust. Iron oxide is a loose and porous material which provides no protection to the underlying steel, which is why rusted regular steel will continue to rust. Stainless steel, in addition to containing iron and carbon, contains chromium as a component--and it's the chromium that is important for corrosion protection. To be fair, even stainless steel rusts but what happens is that it's the chromium that reacts with oxygen to create a microscopically-thin layer of chromium oxide. This layer is very tough and actually protects the uncorroded steel, preventing further corrosion. Broadly speaking, the higher the chromium content, the more corrosion resistant the stainless steel.

- Q: mass of steel ball=66.80 gramsdiameter of steel ball=2.51 cm

- To calculate the density of any object you will always use the formula: Density = Mass / Volume (P=M/V). You have recorded the known values of the mass and the diameter of the ball (sphere), so we have everything needed to calculate the Density. Mass is 66.80g, but we shall need to use another formula to calculate the volume of the sphere. The formula to use is 4/3 X Pi X radius cubed. However, first of all we need to turn your measurement of the diameter of the steel sphere into the radius of the steel sphere (So that it can be substituted in place of the “radius” in the above formula). Simply half the diameter to find the radius. So 2.51 cm divided by 2 is 1.255 cm. Now insert the radius 1.255cm into the above formula. It would be read like this: 4/3 X 3.14159… X 1.255 ?cubed (OR 4/3 X 3.14159 X 1.255X1.255X1.255), = 8.2798. So, now we know that the sphere has a volume of 8.2798 cm cubed, we can use this number in place of the “V” in the density formula P=M/V, and we can also substitute in the Mass (66.80g). So now P=66.80 / 8.2798, which = 8.07g/cm cubed. Now we know that from your measurements, steel has a density of 8.07g/cm cubed! This is fairly close to the real life average density, which if I remember correctly is around 7.8 g/cm cubed. Just remember, though, that as steel is an alloy it’s density is not standard and varies due to carbon content etc. Anyway, I hope that helped you!

- Q: Does steel have a valence number and if so, what is it?

- Steel is a mixture, so it doesn't have any valence number. On the other hand, all of the components of the steel mixture are in their elemental forms, so all the various valences are zero.

- Q: Steel, Sturm, and Kitiara are in a series called the Dragonlance Chronicles.

- Steel Brightblade was conceived when Kitiara and Sturm traveled together five years prior to the War of the Lance. Steel was then born at a woman named Sara Dunstan's house outside Palanthas. Kitiara let Sara raise him and when Sturm died Sara and Steel moved into the city of Palanthas. It's better explained in Second Generation by Margaret Weis and Tracy Hickman. Oh and I don't think the series is over commercialized I think that they could have done more with the original characters and the new characters. I'm also looking forward to the movie when it comes out next Autumn.

Send your message to us

Prepainted galvanized corrugated Plate / Sheet-CGLCC

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords