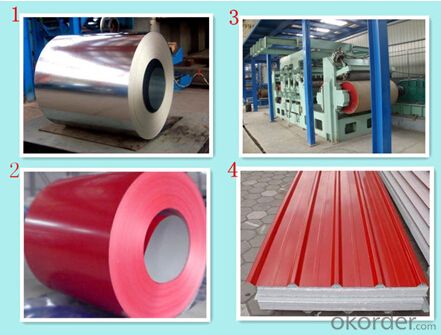

Prepainted Galvanized Steel Coil/PPGI Coil (Printed, Filmed, Matte)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Surface Treatment:Coated

Certification:SGS

Technique:Cold Rolled

Standard:ASTM, JIS, GB, AISI, DIN, BS

Steel Grade:Q235

Emboss Type:Wood Grain, Marble, Brick Grain, Camouflage

Base Sheet:HDG/Al-Zn/Zf

Thickness:0.13-1.5mm

Width:600mm-1500mm

Color:Ral Card Colors

Top Side:20-25um

Back Side:7-12um

Weight of Coil:3-5mt

Type:PE; Hdp; Smp; PVDF

Export Markets:Global

Additional Info.

Packing:Export Packing

Standard:0.13-1.5*600-1250MM

Origin:China

Production Capacity:300000 Mt/Year

Product Description

Specifications

1 thickness: 0.12-1.5mm

2 width: 600-1500mm(914/1000/1200/1220/1250mm)

3 Ral card colors available

Prepainted Steel Coil is made by galvanized steel sheets as substrate and coated by polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc.

Main Processing of PPGI Coil:

(1) The surface pretreatment including degreasing, cleaning, chemical conversion.

(2) Continuous coatings (roller coating method),

(3) Roasting and cooling.

PPGI/PPGL with light weight beautifal appearance and good corrosion resistance can be directly processed so it is widely used in light industry, househould, appliances, automotive and construction industry. For avrious types of industrial and civil construction industry, light steel keel, building level board, corrugated board, roller shutter doors. It was designed to protect steel surface from corrosion, extend its life, in the surface coating layer of Zinc and Color PE metal plate, making improvements to its surface characteristics of thin steel plate.

Printed and color coated heet is a new type of coated sheet which has high decoration performance, with protect, decorate, handsome dispose the coated layer surface. They are widely used in the field of electrical home appliances, decoration and special places.

Packaging & Delivery

Packaging Detail: Seaworthy standard export packing

Delivery Detail: Within 15-25 work days once we get the deposite.

| Available Size for ppgi ppgl color coated galvanized steel coil prepainted galvanized steel coil | |||

| Manufacturer | Thickness | Width | Inner Diameter of Coil |

| ZhengzhouCityUnites Steel Industrial Co., Ltd. | 0.13-1.5mm | 600-1500mm | 508mm,610mm |

| Available Painting for ppgi ppgl color coated galvanized steel coil prepainted galvanized steel coil | |||

| Category of Painting | Iterm | Code | |

| Polyester | PE | ||

| High-durability Polyester | HDP | ||

| Silicon Modified Polyesters | SMP | ||

| Polyvinylidene Fluoride | PVDF | ||

| Easy-cleaning | EC | ||

| Painting Thickness | Top side | 10-20±5microns | |

| Bottom side | 5-7microns | ||

| Back side | 5-7microns | ||

FAQ

1.What's your MOQ?

25MT, it is for one container.

2.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

3. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days. But don't worry ,we also try our best for the delivery time ,because time longer and our cost is higher.

4.Are the products tested before shipping?

Yes, all of our PPGI and GI was qualified before shipping. We test every batch every day

- Q: What are the different finishes available for steel coils?

- Steel coils are available in various finishes, each with its own unique characteristics and advantages. Some of the most commonly used finishes include the following: 1. Hot-dip galvanized: In this finish, the steel coil is immersed in molten zinc, creating a protective layer that prevents rust and corrosion. It offers excellent durability and long-term protection against harsh environmental conditions. 2. Electro-galvanized: Similar to hot-dip galvanizing, this finish involves using an electric current to apply a thin layer of zinc onto the steel coil. It provides good corrosion resistance and aesthetics, making it suitable for different applications. 3. Galvannealed: This finish combines the benefits of galvanizing and annealing processes. The steel coil is first galvanized and then annealed, resulting in a matte grey appearance with enhanced paint adhesion. Galvannealed finishes are commonly used in the automotive and appliance industries. 4. Pre-painted: Also known as coil coating, this finish includes applying a layer of paint onto the steel coil before it is formed into its final product. Pre-painted finishes offer a wide range of colors, textures, and gloss levels, allowing for customization and improved aesthetics. 5. Stainless steel: Steel coils can also be finished with a layer of stainless steel, which provides excellent resistance to corrosion, heat, and chemicals. Stainless steel finishes are often used in applications that require hygiene, durability, and a high-quality appearance, such as in the food and beverage industry. 6. Cold-rolled: To achieve this finish, the steel coil is passed through a series of rollers at room temperature, resulting in a smooth and polished surface. Cold-rolled finishes offer improved dimensional accuracy, surface quality, and flatness, making them suitable for applications that require tight tolerances and a refined appearance. 7. Metallic coated: In this finish, a layer of metallic coating, such as aluminum or zinc-aluminum alloy, is applied to the steel coil. Metallic coated finishes provide excellent corrosion resistance, lightweight properties, and aesthetic versatility. The choice of finish for steel coils depends on specific application requirements, considering factors such as corrosion resistance, aesthetics, durability, and cost-effectiveness. It is important to consult industry experts and manufacturers to determine the most suitable finish for a particular project.

- Q: How are steel coils used in the production of electrical appliances?

- Steel coils are used in the production of electrical appliances as the primary component for creating electromagnets. These electromagnets are crucial for various functions in appliances such as motors, transformers, and generators. The steel coils are wound with copper wires and when an electric current is passed through them, they generate a magnetic field, allowing the appliance to operate efficiently.

- Q: What are the common manufacturing defects in steel coils?

- There are several common manufacturing defects that can occur in steel coils, including surface imperfections such as scratches, pits, or dents, dimensional inconsistencies such as uneven thickness or width, edge defects like burrs or cracks, and internal defects such as inclusions or voids. These defects can impact the quality and performance of the steel coils, and manufacturers strive to minimize these issues through quality control measures and inspections.

- Q: i need working shoes for women that have steel toe shoes? What store do they sell them in . i live in c.a.

- Walmart Steel Toe Shoes

- Q: How are steel coils used in the manufacturing of metal furniture?

- Steel coils are an essential component in the manufacturing of metal furniture. These coils are typically made from high-quality steel, which provides strength, durability, and stability to the furniture. The first step in using steel coils in the manufacturing process is to cut them into the desired length and width. This is done using specialized machinery and tools, ensuring precise and accurate dimensions for the furniture components. Once the coils are cut, they are then shaped and formed into various furniture parts such as chair frames, table bases, or cabinet structures. The coils can be bent, welded, or manipulated to create the desired shapes and designs. After the shaping process, the steel coils are further processed to enhance their aesthetic appeal and protection against corrosion. This involves sanding, polishing, and applying protective coatings or finishes to give the furniture a smooth and attractive surface. In addition to providing structural support and visual appeal, steel coils also contribute to the overall functionality of metal furniture. They offer excellent load-bearing capacity, ensuring that the furniture can withstand weight and pressure without bending or breaking. Moreover, steel coils make metal furniture more resistant to wear and tear, making it suitable for both indoor and outdoor use. They can withstand harsh weather conditions, making them ideal for patio furniture or outdoor seating arrangements. Overall, steel coils are indispensable in the manufacturing of metal furniture, playing a crucial role in providing strength, durability, and aesthetic appeal. Their versatility and reliability make them a preferred choice for furniture manufacturers worldwide.

- Q: What are the different types of steel coil cutting tools?

- In the market, one can find a variety of steel coil cutting tools. These tools have been specifically designed to efficiently and accurately cut steel coils. Some of the commonly used types of steel coil cutting tools include: 1. Slitting shears: These shears are widely utilized to cut steel coils into narrow strips. Equipped with multiple blades, slitting shears offer clean and precise cuts without causing any damage to the material. They are typically employed in high-volume production and are capable of handling different thicknesses of steel coils. 2. Rotary shears: Another commonly used cutting tool for steel coils is the rotary shear. These shears consist of rotating blades that shear through the material as it passes through them. Rotary shears are perfect for cutting medium to thick steel coils and are known for their high cutting speed and accuracy. 3. Guillotine shears: Guillotine shears are heavy-duty cutting tools that can handle thick steel coils. They operate by exerting a downward force to cut through the material in one clean stroke. Renowned for their power and precision, guillotine shears are suitable for cutting large volumes of steel coils. 4. Laser cutting machines: Advanced cutting tools like laser cutting machines employ a high-powered laser beam to cut through steel coils. These machines offer precise and intricate cuts with minimal heat distortion. Laser cutting machines are ideal for cutting complex shapes and patterns on steel coils. 5. Water jet cutting machines: Water jet cutting machines utilize a high-pressure stream of water mixed with abrasive particles to cut through steel coils. This method provides high accuracy and does not generate heat, making it suitable for cutting heat-sensitive materials. Water jet cutting machines can cut through various thicknesses of steel coils and produce smooth edges. Each type of steel coil cutting tool has its own advantages and is suitable for different applications. The choice of tool depends on factors such as the thickness of the steel coil, required precision, production volume, and budget.

- Q: Aluminum alloy rolling doors and color steel shutter door that good

- Among them, aluminum alloy rolling doors and ordinary rolling doors, both from the appearance, environmental protection or safety, have considerable advantages. Aluminum Alloy doors can be sprayed on the surface of various colors and patterns, but also with the concavity of the wood, sand grain coated, highlight the noble temperament, improve grades, if it is used in shops, you can let your talent shows itself in many shops in the.

- Q: Hi there! I just purchased two cookie sheets labeled as non-stick 100% carbon steel. I've never heard of carbon steel before, and I'm trying to be careful about not using certain products that are harmful to health such as aluminum and Teflon. Is this a safe metal choice for baking?

- 100 carbon steel baking sheet safe

- Q: How do you prevent damage to steel coils during transportation?

- To prevent damage to steel coils during transportation, several measures can be taken. Firstly, proper packaging and securing techniques should be employed, such as using strong and sturdy crates or pallets to protect the coils from physical impact. Additionally, using protective materials like foam or padding between coils can help cushion them and minimize movement. Secondly, ensuring that the coils are properly loaded and secured in the transport vehicle is crucial. This includes using appropriate restraints, such as straps or chains, to prevent the coils from shifting or falling during transit. Lastly, employing safe driving practices, such as avoiding sudden stops or sharp turns, can also contribute to preventing damage to steel coils during transportation.

- Q: Search the internet for 'Frost Clipper Knife'. This knife comes in either stainless or carbon steel. I have a friend who has one (stainless steel) and he is very impressed with it, but I have heard that Carbon Steel blades are better? Discuss...

- There are different grades of Carbon Steel. A good grade is much harder than Stainless Steel and will stay sharp longer. It is also many times harder to get an edge on than Stainless Steel. I have had both and prefer the Stainless Steel because eventually the Carbon Blade does get dull, and you will wear out a Whet Stone trying to put the edge back on it. The Stainless Steel holds an edge an acceptable amount of time and is easier to sharpen when the time comes. Putting either knife through a can opener sharpener will ruin the edge and make it almost impossible to put another edge on the knife. Look closely and determine the angel of the bevel, then lay the knife bevel flat on a good whet stone and try to take a thin slice off of the stone. Turn the knife over and do the other side so you keep the edge centered on the blade. Keep turning the knife over and taking thin slices until it is sharp. Dress with a good quality sharpening steel.

Send your message to us

Prepainted Galvanized Steel Coil/PPGI Coil (Printed, Filmed, Matte)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords