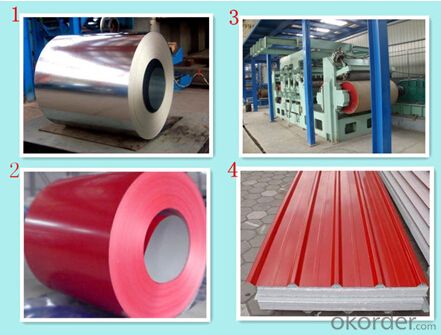

Prepainted Galvanized Steel Coil/PPGI Coils (Printed, Filmed, Matte)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Surface Treatment:Coated

Certification:SGS

Technique:Cold Rolled

Standard:ASTM, JIS, GB, AISI, DIN, BS

Steel Grade:Q235

Emboss Type:Wood Grain, Marble, Brick Grain, Camouflage

Base Sheet:HDG/Al-Zn/Zf

Thickness:0.13-1.5mm

Width:600mm-1500mm

Color:Ral Card Colors

Top Side:20-25um

Back Side:7-12um

Weight of Coil:3-5mt

Type:PE; Hdp; Smp; PVDF

Export Markets:Global

Additional Info.

Packing:Export Packing

Standard:0.13-1.5*600-1250MM

Origin:China

Production Capacity:300000 Mt/Year

Product Description

Specifications

1 thickness: 0.12-1.5mm

2 width: 600-1500mm(914/1000/1200/1220/1250mm)

3 Ral card colors available

Prepainted Steel Coil is made by galvanized steel sheets as substrate and coated by polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc.

Main Processing of PPGI Coil:

(1) The surface pretreatment including degreasing, cleaning, chemical conversion.

(2) Continuous coatings (roller coating method),

(3) Roasting and cooling.

PPGI/PPGL with light weight beautifal appearance and good corrosion resistance can be directly processed so it is widely used in light industry, househould, appliances, automotive and construction industry. For avrious types of industrial and civil construction industry, light steel keel, building level board, corrugated board, roller shutter doors. It was designed to protect steel surface from corrosion, extend its life, in the surface coating layer of Zinc and Color PE metal plate, making improvements to its surface characteristics of thin steel plate.

Printed and color coated heet is a new type of coated sheet which has high decoration performance, with protect, decorate, handsome dispose the coated layer surface. They are widely used in the field of electrical home appliances, decoration and special places.

Packaging & Delivery

Packaging Detail: Seaworthy standard export packing

Delivery Detail: Within 15-25 work days once we get the deposite.

| Available Size for ppgi ppgl color coated galvanized steel coil prepainted galvanized steel coil | |||

| Manufacturer | Thickness | Width | Inner Diameter of Coil |

| ZhengzhouCityUnites Steel Industrial Co., Ltd. | 0.13-1.5mm | 600-1500mm | 508mm,610mm |

| Available Painting for ppgi ppgl color coated galvanized steel coil prepainted galvanized steel coil | |||

| Category of Painting | Iterm | Code | |

| Polyester | PE | ||

| High-durability Polyester | HDP | ||

| Silicon Modified Polyesters | SMP | ||

| Polyvinylidene Fluoride | PVDF | ||

| Easy-cleaning | EC | ||

| Painting Thickness | Top side | 10-20±5microns | |

| Bottom side | 5-7microns | ||

| Back side | 5-7microns | ||

FAQ

1.What's your MOQ?

25MT, it is for one container.

2.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

3. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days. But don't worry ,we also try our best for the delivery time ,because time longer and our cost is higher.

4.Are the products tested before shipping?

Yes, all of our PPGI and GI was qualified before shipping. We test every batch every day

- Q: How are steel coils used in the production of conveyor systems?

- Steel coils are used in the production of conveyor systems as they are transformed into various components such as conveyor belts, rollers, and frames. These components provide the necessary strength, durability, and support required for efficient material handling and transportation in conveyor systems.

- Q: What would be a better knife one with damascus steel or one without? Why is damascus steel so special other than the look? And why do some people say high carbon steel is better than regular? mainly though I want to know about the damascus. Thanks, max points to best answer.

- This Site Might Help You. RE: Is a knife with damascus steel better than one with regular steel? or what about high carbon? What would be a better knife one with damascus steel or one without? Why is damascus steel so special other than the look? And why do some people say high carbon steel is better than regular? mainly though I want to know about the damascus. Thanks, max points to best answer.

- Q: Can steel coils be used in the manufacturing of machinery and equipment?

- Yes, steel coils can be used in the manufacturing of machinery and equipment. Steel coils have high strength and durability, making them suitable for various applications in the machinery and equipment industry. They can be shaped, cut, and formed into various components, such as frames, shafts, gears, and structural parts, to meet the specific requirements of different machinery and equipment. Additionally, steel coils can be further processed and treated to enhance their properties, such as through heat treatment or surface coatings, to improve their performance and longevity in the manufacturing process.

- Q: How are steel coils inspected for defects after rewinding?

- Steel coils are inspected for defects after rewinding through a combination of visual inspection, non-destructive testing (such as ultrasonic testing), and dimensional measurements. These inspections help identify any surface imperfections, internal flaws, or deviations in size, ensuring that the steel coils meet the required quality standards.

- Q: How are steel coils used in the manufacturing of power transmission towers?

- Steel coils are used in the manufacturing of power transmission towers by being cut, shaped, and welded together to form the structural components of the towers. The coils provide a strong and durable material that can withstand the weight and stress of the tower, ensuring its stability and longevity.

- Q: Are steel coils recyclable?

- Yes, steel coils are recyclable. Steel is a highly recyclable material that can be melted down and used to create new steel products, including steel coils. Recycling steel coils helps to conserve natural resources, reduce energy consumption, and minimize waste.

- Q: How do steel coil manufacturers manage inventory?

- Steel coil manufacturers manage inventory by implementing various strategies and techniques. Firstly, they maintain a robust forecasting system to accurately predict demand and plan production accordingly. This helps in avoiding overproduction or stockouts. Additionally, they establish strong relationships with suppliers to ensure a steady supply of raw materials and reduce lead times. Inventory is carefully monitored using inventory management software, which tracks stock levels, identifies slow-moving or obsolete inventory, and enables timely reordering. Just-in-time (JIT) or lean manufacturing techniques are often employed to minimize inventory holding costs. Lastly, regular inventory audits and analysis are conducted to identify areas for improvement and optimize inventory levels for maximum efficiency and profitability.

- Q: i need the same kind of body jewelry they use in the piercing shop but when i go to order them they say stainless steel, not surgical steel, and i have REALLY sensitive skin so i need to be sure, whats the difference?

- There are hundreds of different grades of stainless steel. Jewelery used for piercings should be made of implant grade. Note that the term surgical steel is not a technical term. It doesn't mean anything, although it sometimes refers to what is technically implant grade stainless. Implant grade stainless steel must conform to the ASTM standard 316LVM F-138-00, otherwise the seller cannot call it implant grade. This is something you should always ask about specifically. Are your stainless items F-138-00 compliant? Jewelry that only claims to be stainless isn't good enough. Jewelery sold in mall stands are typically nickel plated, bargain-basement low grade stainless. Allergies to nickel are common.......BUT there is a big difference between allergies, and infections. Infections are caused by bacteria, not by the metal itself, and if you're getting infections it's a sign you're not keeping the piercing clean and sanitary. Simply switching to a different metal won't prevent infections from recurring. To prevent infections you need to take steps to keep new piercing clean and sanitary. the best way to do this is rinse with 50:50 hydrogen peroxide and water daily, then apply some neosporin. hope this helps.

- Q: What are the different types of steel coil surface protection methods?

- There are several types of steel coil surface protection methods, including oiling, painting, galvanizing, and applying protective films. These methods help prevent corrosion, rusting, and damage to the steel surface during storage, transportation, and processing.

- Q: How are steel coils used in the production of elevator components?

- Steel coils play a crucial role in elevator component manufacturing. Crafted from high-quality steel specifically designed to meet the demanding requirements of elevator production, these coils are indispensable. Elevator doors heavily rely on steel coils. These coils undergo processing into flat sheets, which are then cut into desired dimensions for door creation. The doors must possess strength and durability to endure frequent use and ensure passenger safety. Steel coils provide the necessary structural integrity and resistance to deformation, essential characteristics for elevator doors. Furthermore, steel coils find application in the manufacturing of elevator cabins. After processing, the coils are molded into various shapes to construct cabin walls and flooring. Steel's strength and rigidity make it an ideal material for this purpose, enabling it to handle heavy loads and establish a secure and stable environment for passengers. Additionally, steel coils find utility in the production of elevator shafts. Rolled into cylindrical forms and welded together, these coils serve as the structural framework for the shafts. The shafts demand strength and rigidity to support the elevator's weight and ensure smooth and safe vertical movement. Steel coils fulfill these requirements by providing the necessary strength, stability, and load-bearing capacity for this critical elevator system component. To summarize, steel coils play a vital role in the production of elevator components, including doors, cabins, and shafts. Their strength, durability, and versatility make them suitable for creating reliable and secure elevator systems that efficiently transport passengers.

Send your message to us

Prepainted Galvanized Steel Coil/PPGI Coils (Printed, Filmed, Matte)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords