Galvanized PPGI/All Ral color coated steel coils/Sheet/ Pre-painted Steel Coils/ Sheets /PPGI

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Galvanized PPGI Specification:

| Base material | Al-Zn galvanized steel coil.SGLCC |

| Top side: | 15-25µm |

| Back side | 5-8µm |

| Zinc coating : | 30-150g/m2 |

| Width | 700-1250mm |

| Thickness | 0.3-1.0mm , Thickness tolerance: +/- 0.02mm |

| Color | All RAL Color,or be customized |

| Coil ID | 508m&610mm |

| Coil weight | ≤5 tons |

| Packing | standard seaworhty package |

2. Application of Galvanized PPGI

They are mainly used in construction ,light industry, automobile, agriculture, animal husbandry,fishery and commerce,etc industries.

(1) manufacture anticorrosion, industrial and roof boarding,roof grille.

(2) Make home appliance’s case, civil chimney, kitchen utensils.

(3) Corrosion resistant parts of cars.

(4) Food storage, meat and aquatic products’ freezing and processing equipment.

(5) The equipments to store and transport materials, and packing implements.

3.Packaging & Delivery

(1)Metal Band Strapping (2) Outside Diameter Ring (3) Label

(4)Protective Steel Sheet (5) Water and Rustproof paper (6)Steel Sheet

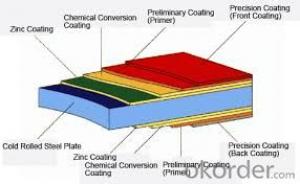

4. Galvanized PPGI image:

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty:

1Year for the whole light. Warranty is based on correct storage, installation, using and maintenanc.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

- Q: Where do I need hot galvanized steel coils and color coated rolls?

- Hot galvanized steel coils and color coated rolls have light, beautiful and good corrosion resistance, and can be directly machinedThe construction industry, shipbuilding, vehicle manufacturing, furniture and electrical industries provide a new type of raw materialThe utility model has the advantages of steel replacing wood, efficient construction, energy saving, pollution prevention and the like.

- Q: How are steel coils welded together?

- Steel coils are typically welded together using one of two methods: either by resistance welding or by arc welding. In resistance welding, the coils are pressed together and an electric current is passed through them, generating heat and causing the coils to fuse together. Arc welding, on the other hand, involves the use of an electric arc that melts the edges of the coils, creating a molten pool. As the pool solidifies, the coils bond together, forming a strong weld. Both methods ensure a secure and durable connection between the steel coils.

- Q: How are steel coils used in the production of food processing equipment?

- Steel coils are commonly used in the production of food processing equipment due to their various advantageous properties. These coils, typically made from stainless steel, are used in the manufacturing of a wide range of equipment such as mixers, blenders, conveyors, ovens, and fryers. One of the main reasons steel coils are used in food processing equipment is their excellent resistance to corrosion. Stainless steel coils are highly resistant to rust and can withstand exposure to moisture and various food substances without deteriorating. This is crucial in ensuring the equipment remains hygienic and safe for food processing. Additionally, steel coils provide exceptional strength and durability, allowing food processing equipment to withstand heavy use and harsh operating conditions. The coils can be formed into different shapes and sizes, enabling the fabrication of complex equipment components. This versatility facilitates the design and construction of equipment that is both efficient and reliable in processing various food products. Furthermore, steel coils are easy to clean and maintain. The smooth surface of stainless steel makes it resistant to staining and facilitates the removal of food residues, preventing the growth of bacteria. Regular cleaning and sanitization of food processing equipment are essential for maintaining food safety standards, and steel coils make this process easier and more effective. Moreover, steel coils have excellent heat conductivity properties, allowing for efficient heat transfer in food processing equipment such as ovens and fryers. This enables precise temperature control and uniform cooking, ensuring consistent quality of processed food products. In summary, steel coils play a vital role in the production of food processing equipment by providing corrosion resistance, strength, durability, ease of cleaning, and efficient heat transfer. These qualities make steel coils an ideal material for manufacturing equipment that meets the high standards of hygiene, safety, and quality required in the food processing industry.

- Q: How much do steel coils weigh?

- The weight of steel coils is subject to variation, which is determined by multiple factors including coil thickness, width, length, and the particular type of steel employed. In general, steel coils can range in weight from a few hundred pounds to several tons. It should be emphasized that the measurement of steel coils typically revolves around their weight per unit area, referred to as the "basis weight" or "coil weight".

- Q: I need to penetrate steel on my car but don't know which bit to use. Are there special bits for steel?

- Yes, they'll be marked HSS, High Speed Steel.

- Q: Can steel coils be coated with fire-resistant materials?

- Yes, steel coils can be coated with fire-resistant materials. This coating can provide an extra layer of protection against fire hazards, reducing the risk of ignition and spread.

- Q: What are the different types of steel coil cutting blades?

- There are several different types of steel coil cutting blades, each designed for specific cutting applications. 1. Slitting Blades: Slitting blades are used for cutting steel coils into narrow strips. They typically have a straight cutting edge and are available in various widths to accommodate different slitting requirements. These blades are commonly used in industries such as automotive, construction, and metal fabrication. 2. Shearing Blades: Shearing blades are designed for cutting steel coils into flat sheets. They have a curved cutting edge that facilitates a clean and precise cut. Shearing blades are commonly used in steel service centers, where large coils are processed into flat sheets for further manufacturing processes. 3. Circular Blades: Circular blades, also known as rotary blades, are used for cutting steel coils in a continuous motion. These blades have a circular shape with sharp teeth around the edge, enabling them to cut through the coil as it passes through the cutting machine. Circular blades are commonly used in industries such as packaging, printing, and paper manufacturing. 4. Guillotine Blades: Guillotine blades are used for cutting steel coils with a straight downward motion. These blades have a straight cutting edge that moves vertically to cut through the coil. Guillotine blades are commonly used in heavy-duty cutting applications, such as cutting thick steel coils or large quantities of material. 5. Slitter Knives: Slitter knives are similar to slitting blades but are typically smaller and used in slitting machines that require multiple blades. They are often used in industries that require high-precision slitting, such as the production of electrical transformers or precision metal stamping. Each type of steel coil cutting blade has its own unique design and characteristics that make it suitable for specific cutting tasks. The selection of the appropriate blade depends on factors such as the thickness and width of the steel coil, the desired cut quality, and the specific application requirements.

- Q: How are steel coils protected against corrosion?

- Steel coils are protected against corrosion through various methods such as applying protective coatings, galvanizing, or using corrosion inhibitors. These measures help to create a barrier between the steel surface and the surrounding environment, preventing the onset of corrosion and extending the lifespan of the coils.

- Q: What are the common coil weight and width combinations available for steel coils?

- The common coil weight and width combinations available for steel coils vary depending on the specific requirements of the industry or application. However, some commonly available coil weight and width combinations for steel coils include: 1. Light gauge coils: These coils typically have a weight range of 5 to 10 tons and a width range of 600 to 1,500 mm. They are commonly used in industries such as automotive, construction, and appliances. 2. Medium gauge coils: These coils generally have a weight range of 10 to 20 tons and a width range of 750 to 2,000 mm. They find applications in sectors like manufacturing, infrastructure, and engineering. 3. Heavy gauge coils: These coils typically have a weight range of 20 to 35 tons and a width range of 900 to 2,200 mm. They are commonly used in industries that require thicker and wider steel sheets, such as shipbuilding, oil and gas, and construction of large structures. 4. Narrow coils: These coils have a width range of less than 600 mm and can have varying weights depending on the specific requirements. They are often used in industries that require narrower strips of steel, such as automotive components, electrical appliances, and packaging. 5. Custom coil sizes: Apart from the above standard coil weight and width combinations, manufacturers can also provide custom sizes based on specific customer requirements. This allows for flexibility in meeting the unique needs of different industries. It is important to note that these weight and width combinations are not exhaustive and can vary depending on the steel manufacturer, production capabilities, and customer demands.

- Q: What are the different types of steel coil finishing processes?

- Enhancing the appearance and properties of steel coils involves employing various steel coil finishing processes. Among the commonly used processes are: 1. Hot-dip galvanizing: Immersing the steel coil in molten zinc forms a protective layer on its surface, enhancing corrosion resistance and providing a visually pleasing finish. 2. Cold rolling: Passing the steel coil through rollers at room temperature reduces thickness and improves surface finish. This process can yield finishes ranging from matte to highly polished. 3. Electro-galvanizing: A thin layer of zinc is electrolytically deposited onto the steel coil's surface. This method is suitable for applications requiring a thinner zinc coating and a more uniform finish. 4. Pickling and oiling: Treating the steel coil with an acid solution removes scale and impurities, resulting in a clean and smooth surface. Coating the coil with oil prevents rust during storage and transportation. 5. Powder coating: Dry powder is applied to the steel coil and cured under heat to form a durable and attractive finish. This method allows for a wide range of colors and finishes. 6. Paint coating: Similar to powder coating, liquid paint is applied to the steel coil's surface. This process offers decorative finishes and protection against corrosion and environmental factors. These examples represent only a few of the available steel coil finishing processes. The choice of method depends on specific application requirements, including desired appearance, corrosion resistance, and durability.

Send your message to us

Galvanized PPGI/All Ral color coated steel coils/Sheet/ Pre-painted Steel Coils/ Sheets /PPGI

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords