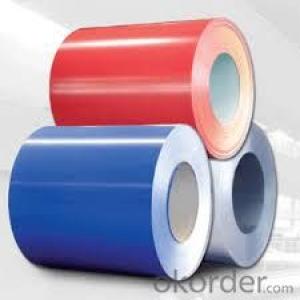

PPGI Steel Coils/Color-Coated Coils/Printed Steel Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

manufacture for GI and PPGI .PPGI Color coated steel coil, prepainted galvanized steel coil ppgi, ppgl.

PPGI Steel Coils/Color-coated Coils/Printed steel Coils

Product Description

NAME:High Quality 0.12-1.5mm PPGI for Roof and Clad\Prepainted Steel Coil\Colour Coated Coil\Coil coated steel

SIZE:

Thickness: 0.12-1.5mm

Width: 30mm-1250mm (STD914mm,1000mm, 1200mm, 1219mm, 1250mm)

Thickness tolerance: +/-0.02mm or control in 0.1 according to customer's requirement

Width tolerance: +/-0.2mm

ZINC, PAINT & COLOR:

Zinc coating: 40-270G/M2 the mainly need is 40-60G/M2

Paint thickness: Top 20-25um + Back 7-10um

Color: As the RAL color standard or customer's sample

Hardness: normal hard (HRB 65); full hard (HRB95) or as per your request

Tensile Strength: more than 270Mpa

Yield Strength: 370-380Mpa,

Packing:

1. Coil weight: 3-5 tons

2. Coil ID: 508mm\610mm

3. Inner side: By water proof kraft paper and plastic packing.

4. Outside: Covered by steel sheet, bundled the sheets with steel strips.

5. Standard sea worthy package or special packing method as per your request

Markets:

We has been exporting steel coils to more than 40 countries and regions directly. Our long term supply extends to Middle East, South Asia, southeast Asia, Africa and eastern Europe and so on. CNBM will be your best business partner.

STANDARD:

JIS G 3312, ASTM A755, EN10169,GB/T2518

Base sheet: Galvanized steel coils\ Galvalume steel, such as SGCC, CGCC, DX51D+Z, Q195,etc

Base metal: Hot galvanized steel or PrePainted Galvanized aLuminium steel or HBR>85

Techinque: Cold rolled, hot-dipped galvanizing, color coated

Quality: CQ DQ prime

Lifespan: 10-15 years

Payment and Delivery Time:

1. Payment: 30% T/T as deposit and 70% balance against copy b/l. Or L/C at sight

or nogotiate.

2. Delivery Time: 7-15 days in receipt of your TT deposit.

APPLICATION.

Outdoor: Roof\ Roof structure\Surface sheet of balcony\ Frame of window\Door of garage\Roller shutter door\Persian blinds\Cabana and so on.

Indoor: Door\Isolater\Frame of door\Light steel structure of house\\Folding screen\Ceiling\Internal decoration of toilet and elevator.

Building accessories: Window panels, signboards Home appliances: Oil/gas boilers, rice buckets, portable gas burners, etc.

Q&A Do you accept OA payment terms?

ANSWER:Yes, sure, but it normally depending on the order value

- Q: Hello, Do I make any damage to my stainless steel sink by cleaning it with clorox? Thank you!

- Thanks to Yahoo about a year ago, I have the perfect answer for you. Below is the recipe for Tub and Tile Cleaner that I copied off Yahoo and I would never go back to using other cleaners again. Ingredients: 2/3 Cup Baking Soda 1/2 Cup Liquid Soap such as dish soap ( I use Palmolive Anti-bacterial ) 1/2 Cup Water 2 Tablespoons White Vinegar Instructions: Whisk together baking soda, soap, and water until smooth and creamy. Add vinegar and let stand a few minutes to foam. Combine all ingredients until thoroughly blended. Store in an airtight container such as one that margarine comes in. Stir prior to using and it doesn't take very much of it either. Use for tubs, toilets, sinks, counter tops extra. This is an excellent cleaner and environmentally safe. Does a great job and your stainless steel sinks will sparkle! In addition to cleaning so well, white vinegar has anti - bacterial properties therefor, this cleaner also kills germs and your drains will smell fresh and clean also. Happy cleaning!

- Q: I need a machine which can produce steel pipes, but I don't know where to look...If you want me to state dimensions etc. just say...Thanks :)

- Gary, Indiana. There's lots of old, unused steel forming equipment just laying around.

- Q: How are steel coils inspected for damage during transportation?

- Steel coils are typically inspected for damage during transportation through visual inspections and non-destructive testing methods such as ultrasonic testing, magnetic particle inspection, and eddy current testing. These inspections help identify any cracks, dents, or other forms of damage that may have occurred during transportation.

- Q: What are the common coil grades available for steel coils?

- The common coil grades available for steel coils are typically classified into three main categories: low carbon steel, medium carbon steel, and high carbon steel.

- Q: How are steel coils used in the production of railway tracks?

- Steel coils are a crucial component in the production of railway tracks. These coils are typically made of high-quality steel and are used to manufacture the rails that form the foundation of the tracks. The process begins with the steel coils being unwound and fed through a series of machines that shape and form them into the desired rail profile. The steel coils are first passed through a rolling mill, where they are gradually flattened and shaped into long strips of steel. This process is known as hot rolling, as the steel is heated to high temperatures to make it more malleable. The rolling mill applies immense pressure to the steel, gradually transforming it into the desired rail shape. Once the steel coils have been rolled into the required shape, they are then cut into individual rail lengths. These lengths can vary depending on the specifications of the railway track being produced. The rail lengths are then further processed to remove any imperfections and straighten them out. After this initial shaping and processing, the rails are subjected to a series of additional treatments. These treatments may include heat treatment to enhance their strength and durability, as well as various surface treatments to prevent corrosion and wear. Once the rails have undergone all the necessary treatments, they are ready to be installed on the railway track. They are laid out in a carefully planned pattern, with each rail securely fastened to the sleepers or ties. The continuous length of steel provided by the coils ensures a seamless and uniform track, allowing trains to travel smoothly and safely. In summary, steel coils play a vital role in the production of railway tracks. They are used to manufacture the rails that form the foundation of the tracks, ensuring durability, strength, and a smooth surface for trains to run on. The use of high-quality steel coils in this process is essential to ensure the safety and efficiency of railway transportation.

- Q: How are steel coils used in the food processing industry?

- Steel coils are commonly used in the food processing industry for various purposes. One primary application is in the production of food packaging materials, such as cans and containers. These coils are transformed into thin sheets or strips that are then formed into the desired shape and size for packaging different food products. Steel coils are also utilized in the manufacturing of equipment and machinery used in food processing plants. This includes machines like conveyors, mixers, and slicers, which are crucial for the efficient and automated processing of food products. The durability and strength of steel make it an ideal material for these types of equipment, as it can withstand heavy usage and maintain its structural integrity. In addition, steel coils are used in the construction of storage and refrigeration facilities within the food processing industry. These coils are transformed into durable and insulated panels that are used to create walls and ceilings of cold rooms, freezers, and warehouses. The excellent thermal properties of steel help maintain the desired temperature and prevent spoilage of perishable food items. Furthermore, steel coils are employed in the production of cooking and baking equipment, such as ovens and grills. These coils are transformed into heating elements that provide consistent and efficient heat distribution during the food preparation process. This ensures that food is cooked or baked evenly, resulting in high-quality and delicious products. Overall, steel coils play a vital role in the food processing industry by providing the necessary materials for packaging, equipment, and infrastructure. Their strength, durability, and thermal properties make them a preferred choice for various applications within this industry, ensuring the production of safe and high-quality food products.

- Q: What are the different types of steel coil slitting processes?

- There exist various steel coil slitting processes, each with its own advantages and considerations. Listed below are some of the most common methods: 1. Rotary slitting: This traditional and widely-used process involves a circular blade that rotates to cut through the coil. Rotary slitting is known for its precision and ability to produce narrow strips, making it suitable for a wide range of applications. 2. Loop slitting: This method requires the coil to pass through a loop before being cut. It enables high-speed processing and can handle thicker materials. Loop slitting is commonly applied in heavy-duty applications and with large coils. 3. Drag slitting: Also referred to as shear slitting, this process utilizes a stationary blade to pull the material and make the cut. Drag slitting is ideal for thinner materials and provides a high-quality edge finish. 4. Crush slitting: By pressing the material between two rollers, crush slitting achieves the desired cut. It is commonly used for delicate materials that require a gentle cutting action. This method ensures clean cuts and minimizes burrs. 5. Laser slitting: As implied by its name, this process employs a laser beam to cut through the coil. Laser slitting provides high precision and can handle various materials. It is especially advantageous for specialty steels and thin strips. When selecting the appropriate method, it is crucial to consider factors such as material thickness, coil size, and required strip width for each type of steel coil slitting process. Additionally, factors like cost, speed, and edge finish should also be taken into account to determine the most suitable process for a specific application.

- Q: What is the role of steel coils in the construction industry?

- Steel coils play a crucial role in the construction industry as they are used to manufacture a wide range of structural components and building materials. These coils are typically made from high-quality steel and are formed into various shapes and sizes to meet the specific needs of construction projects. From reinforcing bars and beams to roofing sheets and wall panels, steel coils provide strength, durability, and flexibility, making them an essential and versatile material in the construction industry.

- Q: How do steel coils contribute to the manufacturing of electrical equipment?

- Steel coils play a crucial role in the manufacturing of electrical equipment due to their unique properties and versatility. Firstly, steel coils are used in the production of transformer cores, which are essential components in electrical equipment. The magnetic properties of steel make it an ideal material for transformer cores as it allows for efficient energy transfer and reduces energy losses. The coil shape of the steel enables it to generate a magnetic field that facilitates the transformation of voltage levels, thus ensuring the proper functioning of electrical equipment. Moreover, steel coils are commonly used in the production of motors and generators. These devices rely on magnetic fields to convert electrical energy into mechanical energy and vice versa. The coil shape of the steel allows for the creation of electromagnetic fields, which are necessary for the operation of motors and generators. Additionally, the strength and durability of steel ensure that the coils can withstand the high temperatures and mechanical stresses that are often encountered in electrical equipment. Furthermore, steel coils are utilized in the construction of electrical conductors, such as wires and cables. These conductors enable the transmission of electricity from power sources to various electrical devices. Steel, with its high electrical conductivity, ensures efficient power transmission while also providing mechanical strength and protection from external factors such as corrosion and wear. The coil shape of steel wires further enhances their flexibility, making them suitable for various applications in electrical equipment manufacturing. Overall, steel coils contribute significantly to the manufacturing of electrical equipment by providing the necessary magnetic properties for transformer cores, enabling the generation of electromagnetic fields in motors and generators, and facilitating efficient power transmission in electrical conductors. Their versatility, strength, and durability make steel coils an indispensable component in the production of reliable and high-performance electrical equipment.

- Q: How are steel coils inspected for straightness using laser alignment?

- Steel coils are inspected for straightness using laser alignment by placing laser sensors on opposite sides of the coil. The laser sensors emit a beam of light which is reflected onto a target. The target detects any deviations or inconsistencies in the laser beam, indicating any irregularities or deviations in the straightness of the coil. The data collected from the laser alignment system is then analyzed to determine if the coil meets the required straightness standards.

Send your message to us

PPGI Steel Coils/Color-Coated Coils/Printed Steel Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords