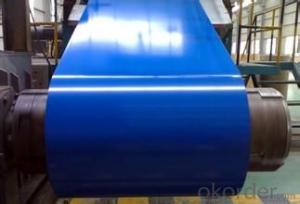

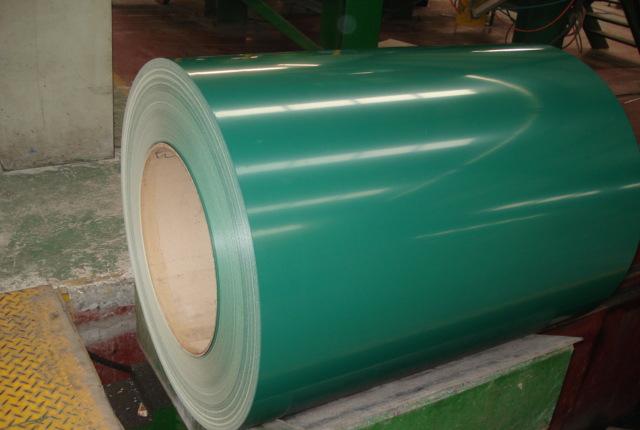

Prepainted Galvanized Steel Coil Best Sell

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 PCS

- Supply Capability:

- 30000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Discription of Top Selling Prepainted Galvanized Steel Coil

OKorder is offering high quality Top Selling Prepainted Galvanized Steel Coil at great prices with worldwide shipping. Our supplier is a world-class manufacturer of galvanized steel and one of the largest production bases in northern China with a strong technical workforce and advanced equipment. We have supplied more than 350000 tons of galvanized steel annually worldwide.

The intended use of Top Selling Prepainted Galvanized Steel Coil

Our Top Selling Prepainted Galvanized Steel Coil is ideal for:

Fabricating applications

Manufacturing applications

The advantage of Top Selling Prepainted Galvanized Steel Coil

Not only are OKorder's Top Selling Prepainted Galvanized Steel Coil of the highest quality and reliability, we are able to quickly ship orders within 20 days of receiving a deposit or original L/C. We also offer training with experienced engineers to ease installation. Products are designed according to customer requirements and are all durable, boast high stiffness and load-bearing qualities, and are recyclable. All products are shipped with ISO9001 & SGS certification as well as JIS 3302, ASTM A653, EN10143 standards.

Main features of our Top Selling Prepainted Galvanized Steel Coil

Additional OEM casting and forging services available

Shipped within 20 Days

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How is our Top Selling Prepainted Galvanized Steel Coil manufactured?

A: Our products are manufactured strictly according to national and international standards, with tests conducted on every product before delivery. Our quality certifications and test reports are available upon request.

Q3: Are products guaranteed?

A: If a product's quality does not match the description provided prior to your order, OKorder offers a full refund.

Q4: Why should you choose us?

A: Sourcing decisions are made based on quality, and then price. We can provide you with both. Additionally, we offer professional product inquiries, product knowledge training (for agents), rapid delivery with factories located near ports and convenient transportation.

Specifications:

Thickness: 0.16mm – 2mm

Width: 500mm, 650mm, 726mm, 820mm, 914mm, 1000mm, 1200mm, 1219mm, 1220mm, 1250mm

Individual Weight: 3 – 8MT

Surface Finish: Chromated, skin pass, oiled, slightly oiled, dry, fingerprint-resistant

Surface structure: Zero spangle, minimized spangle, regular spangle, large spangle

Coil ID: 508mm or 610mm

Coating: 40 – 180g/m² Zinc

Steel Grade: DX51D / DX52D / DX53D / S250, 280, 320GD

Standard: JIS 3302, ASTM A653, EN10143

Images:

- Q: benchmade mpr with m390 steel knife. Is it better than d2 s30v or 154cm steel?

- From what I read M390 is relatively wear resistant, with very high stain resistance and good toughness. It is quite hard to qualify steel as better than other steel because it depends on many factors. E.g. for a small folder designed for delicate cutting D2 at high hardness would perform better, but if the environment is corrosive, like saltwater then M390 would be better. I'm not so sure about using stainless steels in large chopping style knives, but I've seen M390 used for them as well. Obviously hardness had to be lowered, which reduces edge holding ability, especially at low angles. Overall, it's a good steel, but if it will outperform S30V or D2 or 154Cm depends on heat treatment and blade geometry, knife designed use, etc.

- Q: All the steel straps that secure my deck and stair 6x6 posts to the concrete piers have some rust on them. Had bought a rust reducer to spray on them and repaint. As I went to do this I found that one of them is on its last legs, with the steel rusted through and bubbling up all up the sides of the straps. Since this is the end post on a row of 3 deck support posts, I was thinking of removing as much rust as possible, then paint with Rustoleum and cover lower post with something to keep water away from post and pier in the future? Was thinking of something removeable so I could check on it for further rusting. What do you folks with building experience think of this? Thanks.

- Sorry troll, doctors don't give a tetanus shot just because you came into contact with rusty metal. The belief that you need a tetanus shot for stepping on a rusty nail is not quite accurate -- it's not the rust that prompts the shot, it's the fact that the nail was on the ground and dirty.

- Q: I work in a steel foundry 10-12 hours a day where we melt and pour stainless steel tubes. The pour temperature for some of them is very close to the boiling point of stainless steel (about 3800 degrees) because it has to be VERY liquid for the application we use it. Anyway, it does boil a little and we breath in the vapours which I can assure you ARE indeed vapourized stainless steel (it collects and cools on everything and makes a nice shiny coating). Ok, so to the question, does breathing vapourized stainless steel all day pose a health risk such as cancer? Anyone know? I'm just curious.

- you okorder

- Q: How are steel coils used in the manufacturing of aerospace components?

- Steel coils are used in the manufacturing of aerospace components as they provide a reliable and durable material for various applications. The coils are typically cut and formed into different shapes to create components like structural supports, brackets, and fasteners. These components play crucial roles in the construction and assembly of aerospace systems, ensuring strength, stability, and safety in the final products.

- Q: How can the outer diameter and weight of steel coil be converted?

- When it comes to this question, in fact, a lot of them are irrelevant. The weight of the steel rolls means that there is a unit weight called the weight of each mm in the width of the steel coil

- Q: We bought a new fridge and the magnets don't stick to the front where the stainless steel is.

- not all types of stainless steel are attracted by magnets because of certain metals alloyed with the iron. here it is explained on wiki.

- Q: Project for school, we're learning about periodic elements and we have to choose an item from our hobbies to research what its made of. Any ideas on steel guitar strings??

- Steel is usually mainly made up of Iron (Fe) element, but it can also include Carbon (C) for a stronger steel or Nickel (Ni) for stainless steel.

- Q: I was wondering if steel cases can be loaded to the same pressure as brass cases. Are the cartridges that commonly feature steel cases like the Russian 5.45x39, 7.62x39 and 7.62x54R loaded to a lower pressure than their C.I.P. MAPs (380 MPa, 355 MPa, 390 MPa --gt; 51,488 psi to 56,564 psi)? There must be a reason why most NATO armies use brass cases...

- Steel cases are harder to manufacture, but cheaper in material. Loaded? Yes. Those cases are a very mild steel, and will 'flow' well enough to seal at the pressures involved. The question might come up with low pressure loads though. RE-loaded?? - I wouldn't try it, even if they weren't berdan primed.

- Q: How are steel coils used in the manufacturing of HVAC systems?

- Steel coils are used in the manufacturing of HVAC systems as they serve as the main component of heat exchangers, which are responsible for transferring heat between the air and refrigerant. The steel coils provide a sturdy and durable structure for the heat exchanger while also allowing for efficient heat transfer, ensuring optimal performance in heating and cooling processes.

- Q: How are steel coils used in the agricultural sector?

- Various purposes in the agricultural sector call for the widespread use of steel coils. One primary utilization is seen in the construction of farm machinery and equipment. Tractors, plows, harvesters, and other heavy-duty machinery are frequently manufactured using steel coils. The exceptional strength and durability of steel make it an ideal material for such applications, as it can endure the challenging conditions of agricultural work. Furthermore, agricultural buildings and structures heavily rely on steel coils in their construction. Steel is renowned for its superior structural integrity, making it a popular choice for barns, storage units, and other agricultural facilities. Steel coils are frequently employed to establish the framework and support systems of these structures, providing stability and long-lasting durability. Moreover, irrigation systems also rely on steel coils in their production. Steel coils are often used to create the pipes and tubes used for water transportation in agricultural irrigation systems. Steel's resistance to corrosion and its ability to handle high-pressure flows make it an excellent choice for this particular application. To summarize, steel coils hold a critical role in the agricultural sector. Whether it be the construction of farm machinery and buildings or the development of irrigation systems, steel's strength and durability make it the preferred material in this industry.

Send your message to us

Prepainted Galvanized Steel Coil Best Sell

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 PCS

- Supply Capability:

- 30000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords