High Quality of Prepainted Galvanized Steel Coil from China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Pre-Painted Galvanized/Aluzinc Steel Coil Description:

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

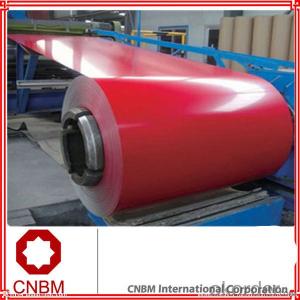

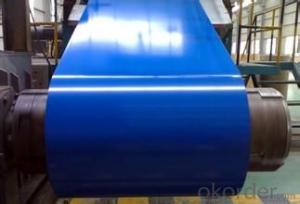

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Brand Name: KMRLON

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Coated

Application: Boiler Plate

Special Use: High-strength Steel Plate

Width: 20-1250mm

Length: customized

commoidty: pre-painted galvanized steel coil

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

color: all RAL color

surface treatment: color coated

coil weight: 4-7 tons

coil ID: 508/610mm

packaging: standard seaworthy packing

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil

What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

- Q: Can steel sheets be used for elevator flooring or platforms?

- Yes, steel sheets can be used for elevator flooring or platforms. Steel is a durable and strong material that can withstand heavy loads, making it suitable for elevator applications. Additionally, steel sheets can be fabricated to meet the required dimensions and specifications for elevator flooring or platforms.

- Q: What are the different surface textures for pre-painted steel sheets?

- There are several different surface textures for pre-painted steel sheets, including smooth, matte, textured, embossed, and patterned.

- Q: Can steel sheets be perforated or punched?

- Yes, steel sheets can be perforated or punched. Perforating or punching involves creating holes or designs in the steel sheet using specialized tools or machinery. This process is commonly used in various industries such as construction, automotive, and manufacturing to achieve specific functionality or aesthetics in the steel sheet.

- Q: Can steel sheets be easily cut?

- Yes, steel sheets can be easily cut using various tools such as shears, plasma cutters, or laser cutters.

- Q: Can steel sheets be used for window frames?

- Yes, steel sheets can be used for window frames. Steel is a strong and durable material that can provide stability and security to window structures.

- Q: What is the average thermal conductivity of steel sheets?

- The average thermal conductivity of steel sheets typically ranges from 15 to 50 Watts per meter Kelvin (W/m·K).

- Q: What is a fixed length steel plate?

- Fixed length: it is a kind of commonly used steel specification, which means that the size of steel supplied is certain.

- Q: Can steel sheets be used for flooring?

- Yes, steel sheets can be used for flooring, especially in industrial or commercial settings. Steel flooring offers durability, strength, and resistance to wear and tear. It is commonly used in warehouses, factories, and other high-traffic areas where heavy loads and frequent foot traffic are expected.

- Q: What is the difference between a hot rolled and pickled steel sheet?

- A hot rolled steel sheet is made by rolling a heated slab of steel through a series of large rollers, resulting in a thick and rough surface finish. On the other hand, a pickled steel sheet undergoes an additional process called pickling, where the surface of the hot rolled steel is treated with an acid solution to remove impurities and create a smooth and clean surface finish. So, the main difference between the two is the surface finish - hot rolled steel has a rougher surface, while pickled steel has a smoother and cleaner surface.

- Q: Can steel sheets be used for storage racks or shelving?

- Yes, steel sheets can be used for storage racks or shelving. Steel sheets are strong, durable, and have high load-bearing capacity, making them suitable for supporting heavy items. They can be easily fabricated into shelves, racks, or even customized to fit specific storage requirements. Additionally, steel sheets are resistant to corrosion, ensuring long-term use in various storage environments.

Send your message to us

High Quality of Prepainted Galvanized Steel Coil from China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords