Prepainted Galvanized steel Coil Good Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Prepainted Galvanized steel Coil Good Qualityil:

With GI as base metal,after pretreatmet (degrease and chemical treatment) and liquid dope with several Layers of color,then after firing and cooling,finally the plate steel is called pre-painted galvanized steel ( PPGI) .Pre-painted galvanized steel is good capable of decoration ,molding,corrosion resistance

2.Main Features of Prepainted Galvanized steel Coil Good Quality:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

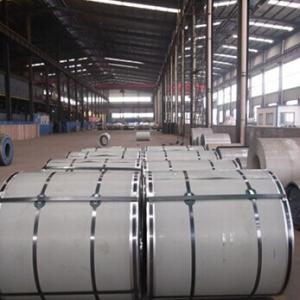

3.Prepainted Galvanized steel Coil Good Quality Images

4.Prepainted Galvanized steel Coil Good Quality Specification:

Standard:ASTM, GB,JIS,JIS G3302 ASTM 755 EN10169

Grade: DX51D CGCC CS

Thickness: 0.13mm~3.0mm,

Width: 1250,600-1250mm

Coil weight:3-12 MT

Coil ID:508/610mm

Chemical composition:

C | Si | Mn | Cr | Ni | P | S |

0.150 | 0.476 | 11.231 | 12.50 | 0.900 | 0.039 | 0.010

|

5.FAQ of Prepainted Galvanized steel Coil Good Quality:

We have organized several common questions for our clients,may help you sincerely:

1.How do you control your quality

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2.How long we will receive the goods ?

After receiving your deposit or workable lc ,our normal shipment date is 15-20days,and it takes around 28 days to reach your port of destination. But is up to different destination

3. What is your MOQ?

Normally our MOQ is 25mt per size ,but it is up to different size.

4.Quality certificate: ISO9001

We have been using a set of production technology and advanced craft from Japan for our production line. We also hired some relevant experts to our factory to provide us very high technology and experience and production skills. We insist quality and safe are first, so that we can supply our customers with good quality and satisfactory products.

- Q: I want to anodize steel using heat. some steel turns gray instead of coloring when I heat it up using a torch.

- Steel doesn't anodize in the sense that aluminum and some other metals do. However, it can be heat-colored. The trick is to clean the surface first (it must be oxide free), then heat gently until the colors appear. These are called temper colors in steel. They are due to a thin adherent layer of oxide that forms and thickens as temperature is increased. They are quite temperature dependent. As the steel is heated, the first color to appear is pale yellow. This will progress through darker yellows, browns, purples, and blues as the temperature rises. Above blue, the oxide becomes the gray/black color you are apparently getting - this is the result of heating too fast and too hot. See the chart at the site below for colors in plain carbon steel. Note that the temperatures are pretty low - It all starts around 400 F and if you go above 600 F the show's all over.

- Q: How are steel coils used in the production of electrical relays?

- Steel coils are used in the production of electrical relays as the electromagnetic core. When an electric current passes through the coil, it generates a magnetic field that attracts or repels the relay's contacts, allowing the relay to switch on or off and control the flow of electricity in various applications.

- Q: What are the challenges in coil blanking for high-strength steel?

- Coil blanking for high-strength steel presents several hurdles due to the unique properties of this material. One of the main obstacles lies in the steel's high tensile strength, which makes cutting and blanking more difficult when compared to traditional steel grades. High-strength steel is typically harder and less malleable, resulting in heightened tool wear and greater cutting forces. Therefore, specialized cutting tools capable of enduring these extreme conditions are necessary. Additionally, the augmented cutting forces can cause increased vibrations, potentially impacting the accuracy and quality of the blanks. Another challenge arises from the spring-back effect displayed by high-strength steel after it is cut. This means that the material tends to return to its original shape, creating difficulties in achieving precise dimensions and tolerances in the blanks. Consequently, careful consideration and adjustment of the cutting parameters are required to minimize the spring-back effect. Furthermore, high-strength steel often contains a higher carbon content, leading to increased work hardening during the blanking process. As a result, the material becomes even harder and more brittle, making it more susceptible to cracks and fractures. To overcome this challenge, proper lubrication and cooling techniques are crucial in reducing heat buildup and minimizing the risk of cracking. Additionally, the heightened strength of the steel can also impact overall production efficiency. The increased cutting forces and tool wear may necessitate a reduction in cutting speeds, resulting in longer processing times. This can affect the productivity and throughput of the coil blanking process, requiring meticulous optimization and planning. In conclusion, the challenges involved in coil blanking for high-strength steel encompass increased cutting forces, tool wear, the spring-back effect, work hardening, and reduced production efficiency. Overcoming these challenges necessitates the use of specialized cutting tools, precise cutting parameters, proper lubrication and cooling techniques, and meticulous optimization of the production process.

- Q: Can steel coils be coated with fluorescent materials?

- Yes, steel coils can be coated with fluorescent materials.

- Q: How do steel coils contribute to the aerospace manufacturing industry?

- Steel coils are an integral component of the aerospace manufacturing industry as they provide numerous benefits and contribute to the overall efficiency and quality of aircraft production. Firstly, steel coils are used in the fabrication of various structural components of an aircraft, such as wings, fuselage, and landing gear. The high strength and durability of steel make it a suitable material for these critical parts, ensuring the safety and reliability of the aircraft. Steel coils provide the necessary raw material for the precise manufacturing processes required in the aerospace industry, allowing for the creation of lightweight yet robust structures that can withstand the demanding conditions of flight. In addition to their structural applications, steel coils are also used in the production of smaller aircraft components. These include fasteners, connectors, and brackets that hold different parts of the aircraft together. Steel's exceptional mechanical properties, including resistance to fatigue and corrosion, make it a preferred choice for such components, ensuring their long-term performance and safety. Moreover, steel coils contribute to the aerospace manufacturing industry by enabling cost-effective production processes. Steel is readily available in large quantities, making it a cost-efficient material for aircraft manufacturing. The ability to produce steel coils in various sizes and thicknesses allows manufacturers to tailor their production to specific aircraft models or design requirements, reducing waste and optimizing resource allocation. Furthermore, steel coils offer inherent recyclability, which aligns with the aerospace industry's growing focus on sustainability. Recycled steel can be used to produce new coils, reducing the need for raw material extraction and minimizing environmental impact. This circularity in the use of steel coils supports the aerospace industry's efforts towards a more sustainable and environmentally friendly manufacturing process. In conclusion, steel coils play a crucial role in the aerospace manufacturing industry by providing the necessary materials for the production of aircraft structures and components. Their strength, durability, and cost-effectiveness make them a valuable resource, ensuring the safety, reliability, and efficiency of aircraft production. Steel coils also contribute to the industry's sustainability goals through their recyclability, aligning with the growing focus on environmental responsibility.

- Q: Can steel coils be coated with aluminum?

- Yes, steel coils can be coated with aluminum. The process is known as the hot-dip method, where the steel is first cleaned and then dipped into a bath of molten aluminum. This results in a protective layer of aluminum coating on the steel surface, enhancing its corrosion resistance and providing aesthetic appeal.

- Q: What are the different methods of coil cutting for steel coils?

- Coil cutting for steel coils encompasses several methods, each boasting unique advantages and application suitability. The following are some commonly used techniques: 1. Slitting: The most frequently employed coil cutting method involves passing the steel coil through rotating circular blades, resulting in narrower strips. Slitting is ideal for precise dimensions and the production of narrow-width strips. 2. Shearing: Another method, particularly suitable for thicker gauge coils, utilizes a straight blade to cut the coil straight. Shearing is optimal for generating larger width strips and is commonly used with heavier gauge steel coils. 3. Laser Cutting: By employing a high-powered laser beam, laser cutting achieves precise cuts through the steel coil. This technique is renowned for its accuracy and ability to cut intricate shapes and patterns. Laser cutting is often employed for specialized applications where fine details and accuracy are critical. 4. Waterjet Cutting: This versatile method employs a high-pressure jet of water mixed with abrasive particles to cut through the steel coil. It can be used to cut various materials, including steel, and produces clean and precise cuts without heat-affected zones. 5. Plasma Cutting: Plasma cutting employs a high-temperature plasma arc to melt through the steel coil. This efficient technique is well-suited for cutting thick gauges of steel and offers high cutting speeds, making it ideal for industrial applications. 6. Guillotine Cutting: Guillotine cutting utilizes a guillotine-like mechanism to cut through the steel coil. The coil is placed on a table, and a vertically descending blade achieves straight and accurate cuts with minimal burrs. The selection of the coil cutting method depends on factors such as desired strip width and thickness, required precision, production volume, and specific application. To determine the most suitable method for a particular steel coil, it is crucial to consider these factors and consult experts.

- Q: How are steel coils used in the manufacturing of intake manifolds?

- Steel coils are typically used in the manufacturing of intake manifolds as the primary material for forming the manifold's structure. These coils are shaped and cut into specific dimensions to create the necessary components, such as runners and plenums, which help regulate the flow of air and fuel mixture into the engine. The steel coils are often subjected to additional processes, including welding, machining, and surface treatments, to ensure the final intake manifold meets the required specifications and performance standards.

- Q: What are the applications of steel coils in automotive manufacturing?

- Due to their unique properties and characteristics, steel coils find a wide range of applications in automotive manufacturing. They offer numerous benefits and contribute significantly to the overall performance, safety, and reliability of automobiles. One primary application of steel coils in automotive manufacturing is their use in the production of body panels. These coils are employed to create the outer body structure of vehicles, including doors, hoods, fenders, and roofs. The exceptional strength and durability of steel make it an ideal material for these components, providing protection against impacts and enhancing the overall structural integrity of the vehicle. Automotive chassis and frames also rely on steel coils during their manufacturing process. The robust and rigid nature of steel makes it an excellent choice for these critical components, enabling them to withstand heavy loads and provide stability to the vehicle. Steel coils ensure that the chassis and frames possess the necessary strength and stiffness to support the weight of the vehicle and endure the forces experienced during driving. Moreover, steel coils play a crucial role in the production of various suspension and steering components, such as springs, stabilizer bars, and control arms. These parts require high strength and resistance to fatigue, as they constantly face stress and vibrations. Steel coils provide the required toughness and flexibility to these components, ensuring smooth and controlled vehicle handling. Furthermore, steel coils find application in the manufacturing of engine parts and exhaust systems. The high-temperature resistance and corrosion resistance of steel make it an ideal material for these purposes. Steel coils are shaped into various forms, including tubes and pipes, to create exhaust manifolds, catalytic converters, and mufflers. They play a significant role in enhancing the performance and efficiency of the engine while reducing harmful emissions. In summary, steel coils are indispensable in automotive manufacturing due to their strength, durability, and versatility. They are utilized in the production of body panels, chassis, suspension components, engine parts, and exhaust systems. The incorporation of steel coils in these applications ensures the safety, reliability, and optimal performance of vehicles, making them an essential material in the automotive industry.

- Q: How are steel coils tested for strength?

- Steel coils are typically tested for strength through a variety of methods, including tension, compression, and bending tests. These tests involve subjecting the coils to various levels of force to determine their resistance and ability to withstand pressure without deformation or failure. Additionally, non-destructive techniques such as ultrasonic or magnetic particle testing may be employed to detect any imperfections or weaknesses within the coils.

Send your message to us

Prepainted Galvanized steel Coil Good Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords