Aluminum Sheets in New Jersey - Prepainted Aluminum Coils for Outer Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

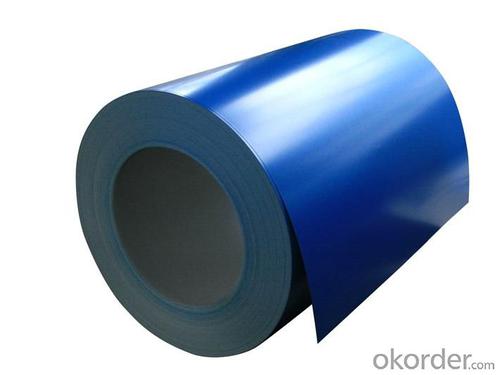

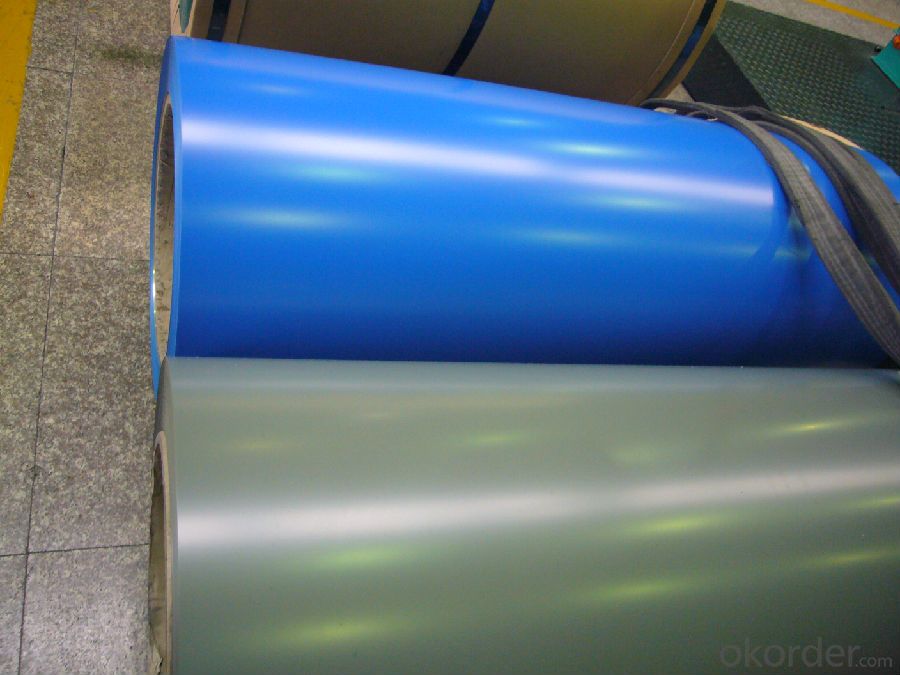

1.Structure of Prepainted Aluminium Coils for Outer Decoration

Prepainted Aluminium Coils for Outer Decoration are widly used in decoration field. For the painting, it depends on the using evironment. If you use in the open air, we recommend the PVDF coated aluminium coils. This kind of painting can last 15-20 years. If you use in the room, we recommend PE coated aluminium coils. The price is much more competitive.

2. Main features of Prepainted Aluminium Coils for Outer Decoration

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image

4. Product Specification

| Alloy | Temper | Coating | Coating Thickness | Weight |

| AA1050 | H14 | Polyester | 20-25microns | about 2 TONS |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: How do you prevent distortion of aluminum sheets during welding?

- Distortion of aluminum sheets during welding can be prevented by implementing several measures. Firstly, utilizing proper welding techniques such as using appropriate heat input, controlling the welding speed, and using a suitable welding process can minimize distortion. Additionally, employing proper fixturing and clamping techniques to secure the sheets in place during welding can help maintain their shape. Pre-heating or post-weld heat treatment can also be employed to alleviate residual stresses and minimize distortion. Lastly, selecting the right filler material and adjusting its composition can aid in reducing distortion during the welding process.

- Q: aluminum is used to make planes, cast iron is used to make heavy mashines. what is the comparisonof teh densities of aluminum and cast iron?

- The density of aluminum is MUCH lower than cast iron (thus, aluminum is LIGHTER). Because it is lighter, it would be much more ideal for applications like plane building, which is why aluminum is used over cast iron in airplanes. As well, aluminum has a protective coating called aluminum oxide which protects it from corroding in water. [Answer: see above]

- Q: Are aluminum sheets suitable for architectural facades?

- Yes, aluminum sheets are highly suitable for architectural facades. They offer numerous benefits such as durability, lightweight construction, corrosion resistance, and versatility in design. Aluminum sheets can be easily shaped and formed into various sizes and shapes, allowing for creative and unique architectural designs. Additionally, their ability to withstand harsh weather conditions makes them a reliable choice for long-lasting facades.

- Q: Is it possible to incorporate windows made from recycled materials into a construction project?

- <p>Yes, you can use windows made from recycled materials in your project. There are eco-friendly windows available that are manufactured using recycled glass or other sustainable materials. These windows can offer similar performance to traditional ones while reducing the environmental impact of your construction. It's important to check the quality and certifications of the recycled windows to ensure they meet your project's requirements.</p>

- Q: Does anyone know why Mercury -(Thimerosal) is used in Flu Vaccinations and where Mercuryisnot used Aluminium in other vaccines ? While these are known to be toxic metals, can these cause headaches, severe hot burning heads and or Sinusitus ?

- Thimerosal is not the same as mercury. It's a mercury-based preservative which to prevent the growth of germs, bacteria and fungi, that can contaminate them. It's used in seasonal flu vaccine because the vaccine is produced in large quantities and often in multi-dose vials. Thimerosal helps safeguard against possible contamination of the vial once it is opened. The aluminum in vaccines is aluminum hydroxide, aluminum phosphate, alum (potassium aluminum sulfate), or mixed aluminum salts. They're an adjuvant added to enhance the immune response in the vaccinated individual. Whether or not something is toxic has to do with how much a person receives not the substance itself. People can die from drinking too much water, but we don't go around calling water toxic. The amount of mercury or aluminum in vaccines is so small that it's not toxic. You ingest more mercury by eating fish and a baby ingest more aluminum in breast milk than they get in a vaccine. So if mercury and aluminum caused head aches, severe hot burning heads or sinusitis in a person, that person would have a lot more to worry about than vaccines since they would be exposed to those things in so many other ways.

- Q: How do you prevent fingerprints on aluminum sheets?

- There are several strategies you can use to prevent fingerprints on aluminum sheets: 1. Opt for gloves: To avoid leaving fingerprints on aluminum sheets, a simple solution is to wear gloves while handling them. This creates a barrier between your hands and the surface, preventing any marks or smudges. 2. Thoroughly clean the surface: Before touching aluminum sheets, ensure that the surface is clean. Use a suitable cleaning agent or mild detergent to remove any dirt or oils. Dry the sheets completely with a lint-free cloth to minimize the chances of fingerprints sticking to the surface. 3. Apply a protective coating: Prevent fingerprints by applying a protective coating on the aluminum sheets. Clear lacquer or a clear protective film designed for this purpose are viable options. These coatings create a barrier that reduces the visibility of fingerprints and makes them easier to clean off. 4. Handle with care: Minimize direct contact with aluminum sheets to reduce the likelihood of fingerprints. Fingerprints are more likely to occur when pressure is applied or when the surface is repeatedly touched. Whenever possible, use tools or gloves to manipulate the sheets instead. 5. Proper storage: Ensure that aluminum sheets are stored in a clean and dust-free environment, away from potential contaminants. Consider using protective sleeves or covers to shield the sheets from fingerprints and other marks. By implementing these preventive measures, you can significantly decrease the occurrence of fingerprints on aluminum sheets, maintaining their cleanliness and visual appeal.

- Q: Can 101 aluminum sheets be used in the production of sporting goods?

- Yes, 101 aluminum sheets can be used in the production of sporting goods. Aluminum is a versatile material that offers several benefits for sporting equipment. It is lightweight, which is crucial for many sports equipment like bicycles, tennis rackets, and baseball bats, as it allows for easier handling and maneuverability. Additionally, aluminum is corrosion-resistant, ensuring the longevity of the sporting goods even when exposed to various weather conditions. It also provides excellent strength-to-weight ratio, making it suitable for high-performance equipment that requires durability without adding unnecessary weight. Therefore, 101 aluminum sheets can be a viable choice for manufacturing various sporting goods, providing the desired properties needed for performance, longevity, and user experience.

- Q: How much weight/people can a 12ft aluminum boat hold?and if anyone knows how much weight can a 6.5hp motor push around

- You should have a small metal plate that is riveted into the rear transom that will tell you what the max. capacity, persons and weight. If this is absent, I would answer the question by saying that if your boat is of the John boat variety, (square front end) and pretty shallow sides, I would think twice about 2 large people that weigh 225+. If your boat is of the deep-V variety with deeper sides, then two people with gear would probably be fine. Any way you look at it, a 10 boat is a maximum of twp persons.

- Q: If you're familiar with some of my previous questions, you'll know I have a thing for DC-3's, and I'd like to buy one and fix it up at some point in my life. I was looking at pictures on Google for my desktop background and saw several with shiny chrome/aluminum bodies. Well, first of all, is it chrome or polished aluminum? Second, would I be able to buy a DC-3 painted this God-awful forest green and put whatever it is (chrome/aluminum) on said plane? Or is it something that the plane has to be built with originally?

- The polished aluminum that DC3's carried (actually any airplane) is the unfinished aluminum that they were built with. It takes lots and lots of work to remove old paint and then polish to get the shine you want. You can not chrome the aircraft, It has to be polished then kept polished and that isn't easy. PS - a repaint is much easier and protects the raw materials much better. However, I agree that a polished aluminum aircraft is very pretty.

- Q: Can aluminum sheet be used for electronic components?

- Yes, aluminum sheet can be used for electronic components. Aluminum is a commonly used material in the electronics industry due to its lightweight, corrosion resistance, and good thermal conductivity. It is often used for heat sinks, casings, and electrical connectors in various electronic devices.

Send your message to us

Aluminum Sheets in New Jersey - Prepainted Aluminum Coils for Outer Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords