Pre-painted Rolled Coil for Construction Roof

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 25 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Prepainted Rolled steel Coil for Construction Roofing

Description of Prepainted Rolled steel Coil for Construction Roofing

Prepainted Rolled steel Coil is a kind of coated steel coil/sheet. With the cold rolled steel of different strength and thickness as substrate, it is produced through applying Al-Zn coat on both faces by hot dip process. In its coating, Al accounts for about 55%, Si 1.6%, while the remaining is Zn. Aluminum zinc coils enjoys both the physical protective feature and durability of Al and the electrochemical protective property of Zn. And its surface has bright silver color and regular embossed-like figure, which are highly decorative.

Main Feature of Prepainted Rolled steel Coil for Construction Roofing

1.Corrosion resistance: It mainly depends on the aluminum protection. When the zinc being worn, the aluminum will form a dense layer of aluminum oxide, resist corrosion material to prevent further corrosion inside.

2. Heat resistance: Aluminum zinc alloy steel sheet has excellent heat resistance, can withstand high temperatures over 300 centigrade, and is similar with aluminized steel high temperature oxidation resistance. It often used in chimney pipes, ovens, fluorescent lighting device and the device cover.

3. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials.

4. Economy: Because density of 55% AL-Zn is smaller than the density of Zn, so in the same weight and thickness of Galvanized zinc layer, aluminum-zinc steel plate is larger area more than 3% of galvanized steel sheet.

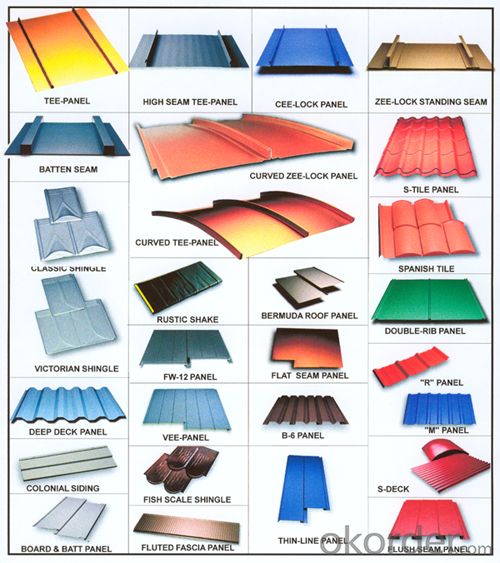

Applications of Prepainted Rolled steel Coil for Construction Roofing

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; road sign; etc.

4.Agriculture:barn; etc.

5.Others:vending machine; game machine; etc.

Specifications of Rolled steel Coil for Construction Roofing

Product | Prepainted Rolled steel Coil for Construction Roofing |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.2-3.0mm |

Width | 600-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | AZ40-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM |

Coil weight | 10MT max |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Prepainted Rolled steel Coil for Construction Roofing

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What are the different types of surface defects in steel coils?

- Some common types of surface defects in steel coils include scratches, pits, rust, scaling, laminations, and waviness.

- Q: What are the different methods of uncoiling steel coils?

- There are several methods used for uncoiling steel coils, including hydraulic uncoiling, motorized uncoiling, and manual uncoiling. Hydraulic uncoiling involves using hydraulic cylinders to unwind and release the tension in the coil. Motorized uncoiling utilizes a motorized mandrel or decoiler to unwind the coil. Manual uncoiling, on the other hand, requires physical effort to unwind the coil by hand. Each method has its own advantages and is chosen based on the specific requirements and capabilities of the uncoiling process.

- Q: What are the different types of steel coil storage systems used during processing?

- There are several types of steel coil storage systems used during processing, including coil racks, coil cradles, coil saddles, coil cars, coil turnstiles, and coil transfer cars.

- Q: steel structure

- Disadvantages Of Steel

- Q: How do steel coils compare to aluminum coils?

- Steel coils and aluminum coils possess distinct characteristics that render them suitable for varying purposes. Firstly, steel coils are renowned for their robustness and durability. They can endure high temperatures and exhibit greater resistance to damage in comparison to aluminum coils. Consequently, steel coils are an ideal choice for heavy-duty industrial applications necessitating sturdy materials, such as construction, automotive manufacturing, and the oil and gas industries. Additionally, steel coils boast heightened corrosion resistance, enabling their usage in outdoor environments characterized by harsh conditions. On the contrary, aluminum coils are lighter in weight and possess a higher strength-to-weight ratio than steel coils. This renders them exceptionally well-suited for industries wherein weight serves as a critical factor, such as aerospace and transportation. Furthermore, the malleability of aluminum coils facilitates easier shaping and forming, thereby proving advantageous in industries like packaging and consumer electronics. Moreover, aluminum coils exhibit superior thermal conductivity when compared to steel coils, rendering them more efficient in heat transfer applications. This particular attribute proves beneficial in industries such as HVAC (heating, ventilation, and air conditioning) and refrigeration, where the achievement of efficient heat exchange is of utmost importance. Concerning cost, steel coils generally prove more affordable due to the lower cost of raw materials. However, aluminum coils can yield long-term cost savings as they require less maintenance and possess a longer lifespan owing to their resistance to corrosion. In conclusion, the selection between steel coils and aluminum coils hinges on the specific requirements of the application at hand. Steel coils are favored for their strength, durability, and corrosion resistance, while aluminum coils excel in lightweight applications, heat transfer, and malleability.

- Q: I'm trying to buy a Survival,tactical knife but don't know what steel is better

- Depends on the grade of metal and how it is tempered. Poor grade or any steel is worthless. Poor temper on quality steel is worthless. I have several 440 Stainless Steel knives that hold a edge very well. But I to have several carbon steel knives that also hold a fine edge. It pretty much boils down to you get what you pay for, top quality don’t come cheap. I prefer name brands like Puma, Buck, S.O.G, Gerber and Old Timer. These brands have never failed me yet. A $5.00 knife is a $5.00 knife , where as S.O.G, and Puma can run you a couple hundred dollars easy. But I have field dressed 5 deer and that was cutting through the pelvic bone of all 5 deer before dulling my Puma, but back in 1978 that puppy cost me $65.00. For Tactical knives S.O.G is my favorite. Don’t be fooled by the cheesy Rambow survival knives, remember the key word is survival so your life may some day rest on the quality knife you buy. It don’t have to have a cheap compass or hollow handle to hold fish hooks and matches. It needs to be a knife you can bet your life on. Look at the knives that the military special forces use today S.O.G makes up most of them Either the S.O.G “Seal pup” used by the Army Rangers or the full sizes “Seal” used by other military special forces teams. ( my son was a trainer for the U S Army Rangers and he was issued a S.O.G Seal Pup) I would suggest you invest in a high quality knife, you can always make up a small survival kit using quality hooks and matches and a quality compass. Remember your life may some day rest on what you invest in. You would not buy cheesy health insurance, now would you? D58 Hunting with Rifle, Pistol, Muzzle loader and Bow for over 3 decades. Reloading Rifle, Pistol and shotgun for over 3 decades.

- Q: How are steel coils annealed for improved properties?

- Steel coils are annealed for improved properties by heating them to a specific temperature and then slowly cooling them down. This process, known as annealing, helps to relieve internal stresses in the steel, increase its ductility, and improve its machinability.

- Q: ex: boat hull made out of steel

- Galvinized means steel with a zinc coating. It is the best. For boats at port, and other fixed objects this can be supplimented with cathodic protection, an electrical method that substitutes corrosion of a sacrificial anode for the rusting of the steel. Epoxy and other coatings tend to be very temporary as they wear and scratch with use and lose all effectiveness if they cannot exclude seawater from contacting the bare metal. Zinc responds to abuse and can 'heal' over minor dings. The zinc is refreshed by periodic painting with a high zinc content paint or by electroplating.

- Q: Can anyone tell me what that means. I have seen it on knife blades an such. I am assuming it's a formula for the strength of the metal. who does that scale work, and please keep it simple.

- 440 is an AISI (American Iron and Steel Institute) material specification. It specifies the precise quantities of carbon and other elements present in the alloy. Here are the constituents of AISI 440 steel: Carbon - 0.6 to 0.75% Chromium - 16 to 18% Manganese - less than 1% Molybdenum - less than 0.75% Phosphorus - less than 0.04% Silicon - less than 1% Sulfur - less than 0.03% Iron makes up the remainder. AISI 440 is a heat-treatable, precipitation-hardening stainless steel.

- Q: what is the porpose of preheating mild steel prior to welding

- ok dont listen to bob the builder down there, u preheat thicker steels to draw moisture out of them. take a propane torch to something exposed to just atmospheric air around 3 inches thick and the water will literally pour out of it. do u want that in ur weld? no. so u preheat to draw any moisture or contaminates out of the base metal. good luck.

Send your message to us

Pre-painted Rolled Coil for Construction Roof

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 25 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords